Overflow valve

An overflow valve and overflow technology, which is applied in the field of sanitary ware, can solve the problems of reducing drainage speed, etc., and achieve the effects of improving overflow capacity, reducing noise, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

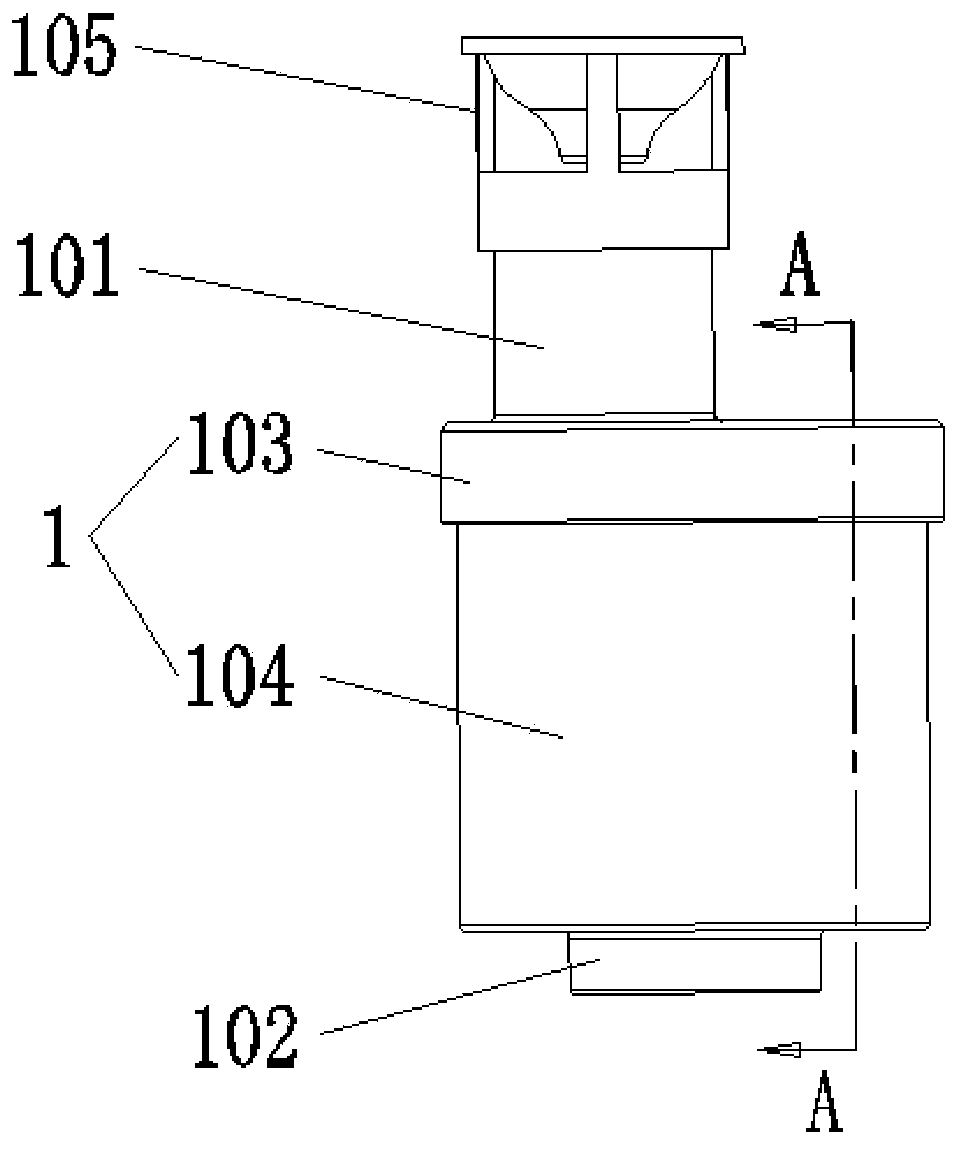

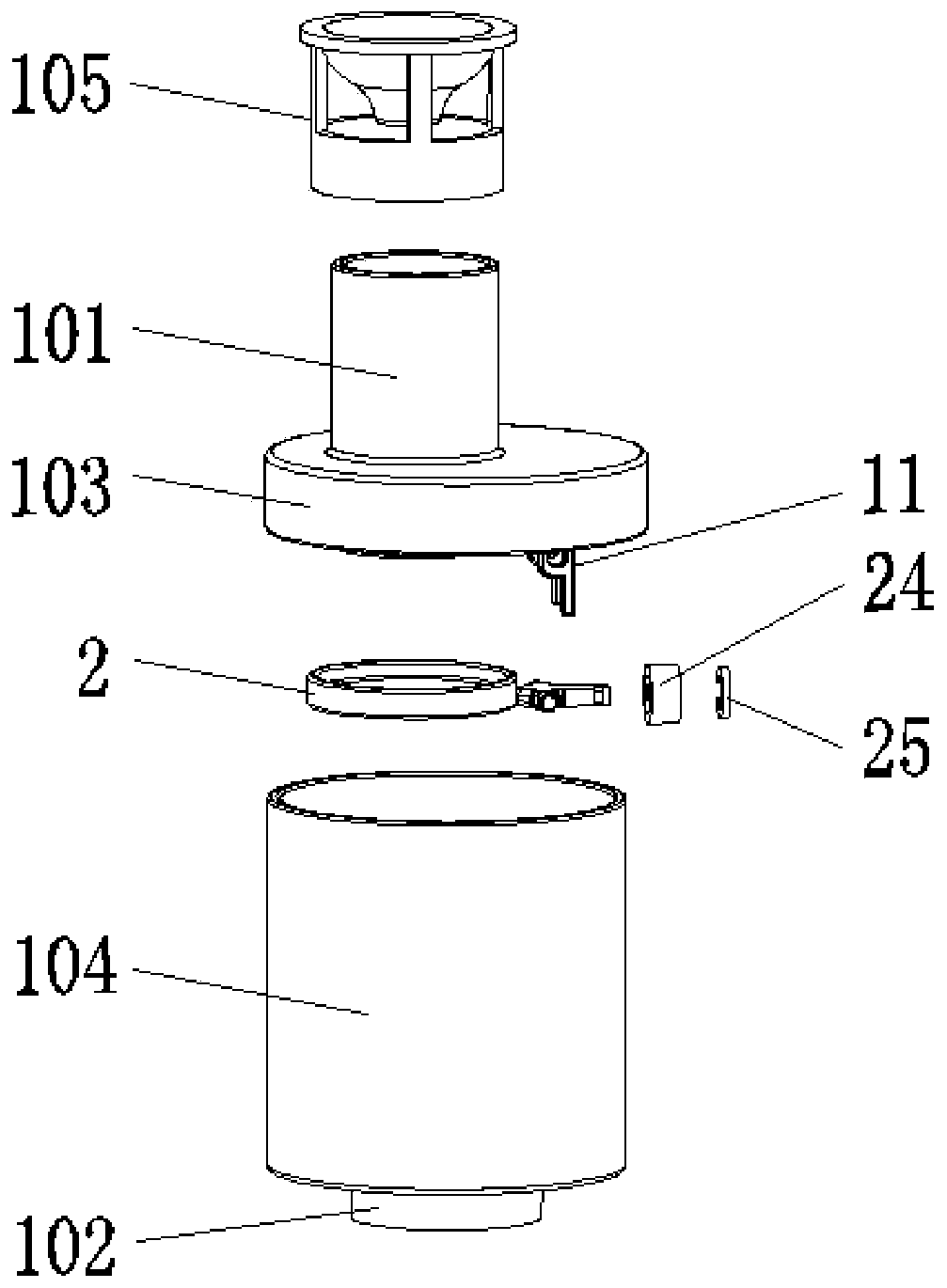

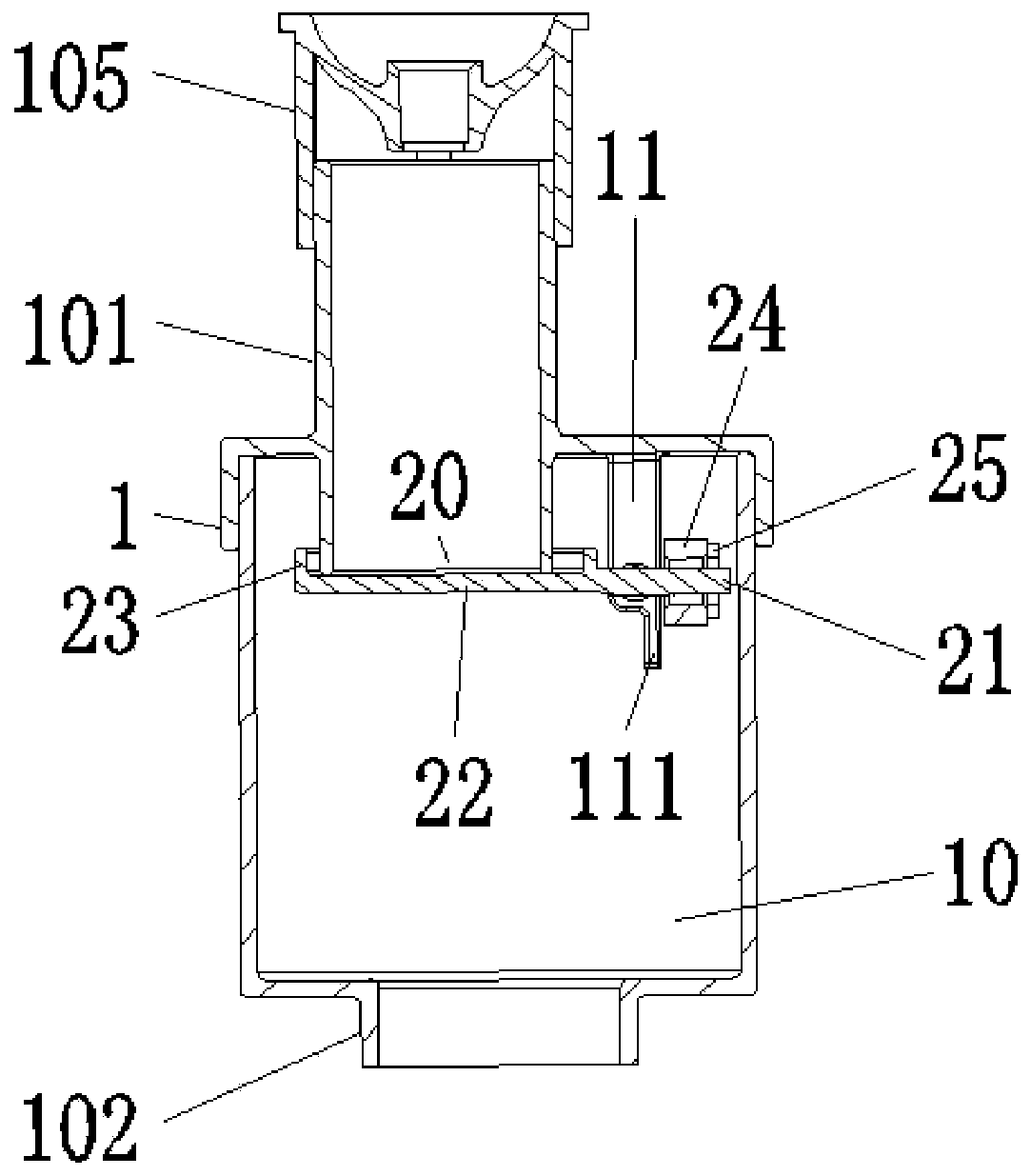

[0041] Such as Figure 1-6 As shown, an overflow valve includes a housing 1 and a swing lever assembly. A water guide chamber 10 is opened inside the housing 1. The top and bottom of the housing 1 are respectively provided with a water inlet pipe 101 and a The drain pipe 102 and the bottom of the water inlet pipe 101 extend into the water guiding cavity 10 . A support is fixed on the top of the water guide chamber 10 at the side of the water inlet pipe 101 . The support includes two support plates 11 arranged in parallel and spaced apart from each other. The support plates 11 are provided with positioning holes 110 .

[0042] The swing lever assembly 2 includes a lever guide column 21 whose middle part is hinged to the bottom of the support, a water seal structure fixed at one end of the lever guide column 21 close to the water inlet pipe 101, and a water seal structure fixed at the other end of the lever guide column 21 and used for sealing with the water. The structure form...

Embodiment 2

[0052] Such as Figure 14-16 As shown, the difference between this embodiment and Embodiment 1 is that the load is a spring 26, and the top wall of the water guide chamber 10 is fixedly provided with a connecting rod 12 on the side of the support, and the lower part of the connecting rod 12 is lower than the lever guide post. 21 A horizontal plate 13 is fixed on the position of the hinged fulcrum, the lower end of the spring 26 is fixed on the horizontal plate 13, and the upper end is connected with the bottom of the lever guide column 21 and is in a stretched state. The rest of the structure of this embodiment is the same as that of Embodiment 1.

[0053] Such as Figure 17 As shown, under normal circumstances, the lever guide post 21 is due to the pulling force of the spring 26, the moment M1 produced by the spring 26 is greater than the moment M2 at the other end of the lever guide post 21, and the lever guide post 21 is in a closed state ( Figure 17 a); when the water s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com