Coal mining process including prop type mining and prop recovery

A coal pillar and pillar-type technology, which is applied in the field of coal mining technology, can solve the problems of waste of resources and low coal recovery rate, and achieve the effects of less investment, less technical work and high safety factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

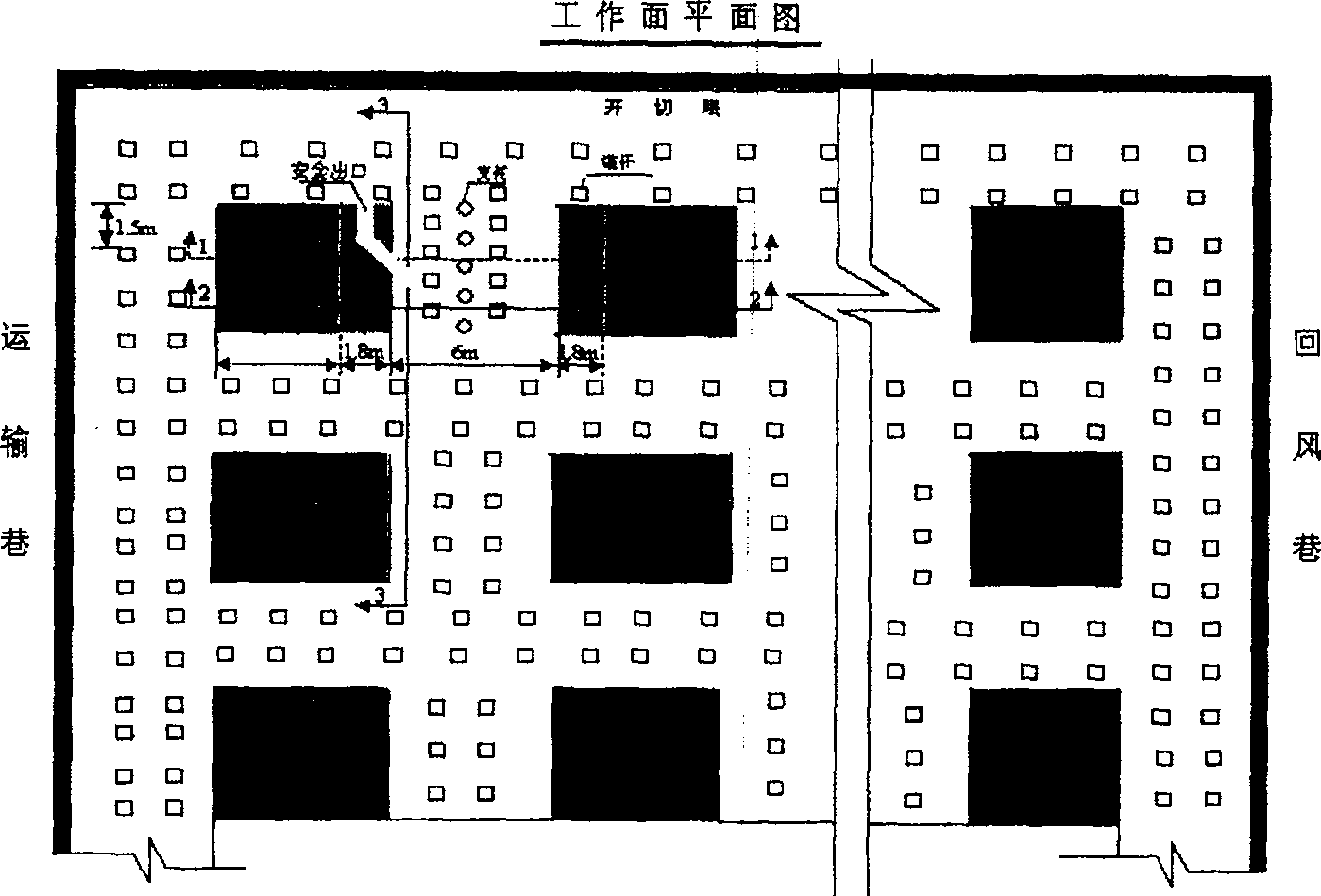

[0032] Embodiment 1: The geological situation of the coal mine is as follows: the average thickness of the coal seam is 8 meters, and the mining height is 3.2 meters; the horizontal coal seam; low gas; the direct roof is sandy mudstone, sandy shale; no false roof and old roof; no water spray.

[0033] The coal mining process of pillar mining recovery coal pillar includes the following steps:

[0034] (1), hit the bolt; (2), hit the pillar; (3), drop the coal; (4), hit the bolt again; (5), load the coal, transport the coal; (6), return the pillar, put the roof Coal and coal pillars; of which

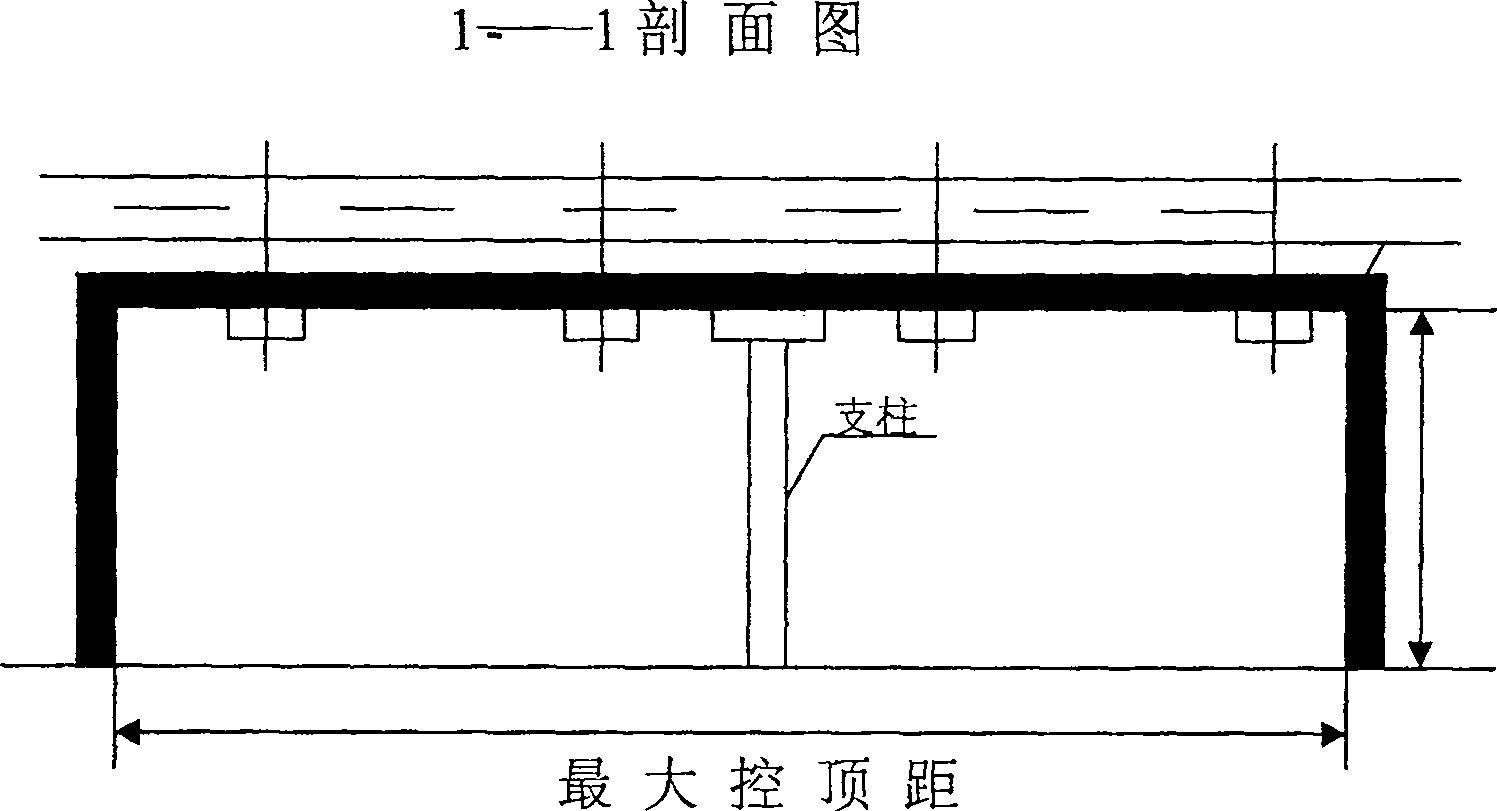

[0035] (1), bolting: at first hit the bolt on the roof in the roadway that has been mined; the bolting is manual bolting. The distance between rows and columns between every two anchors is 2.0m, the length of the anchors is 1.5m, and the diameter of the anchors is 0.16m.

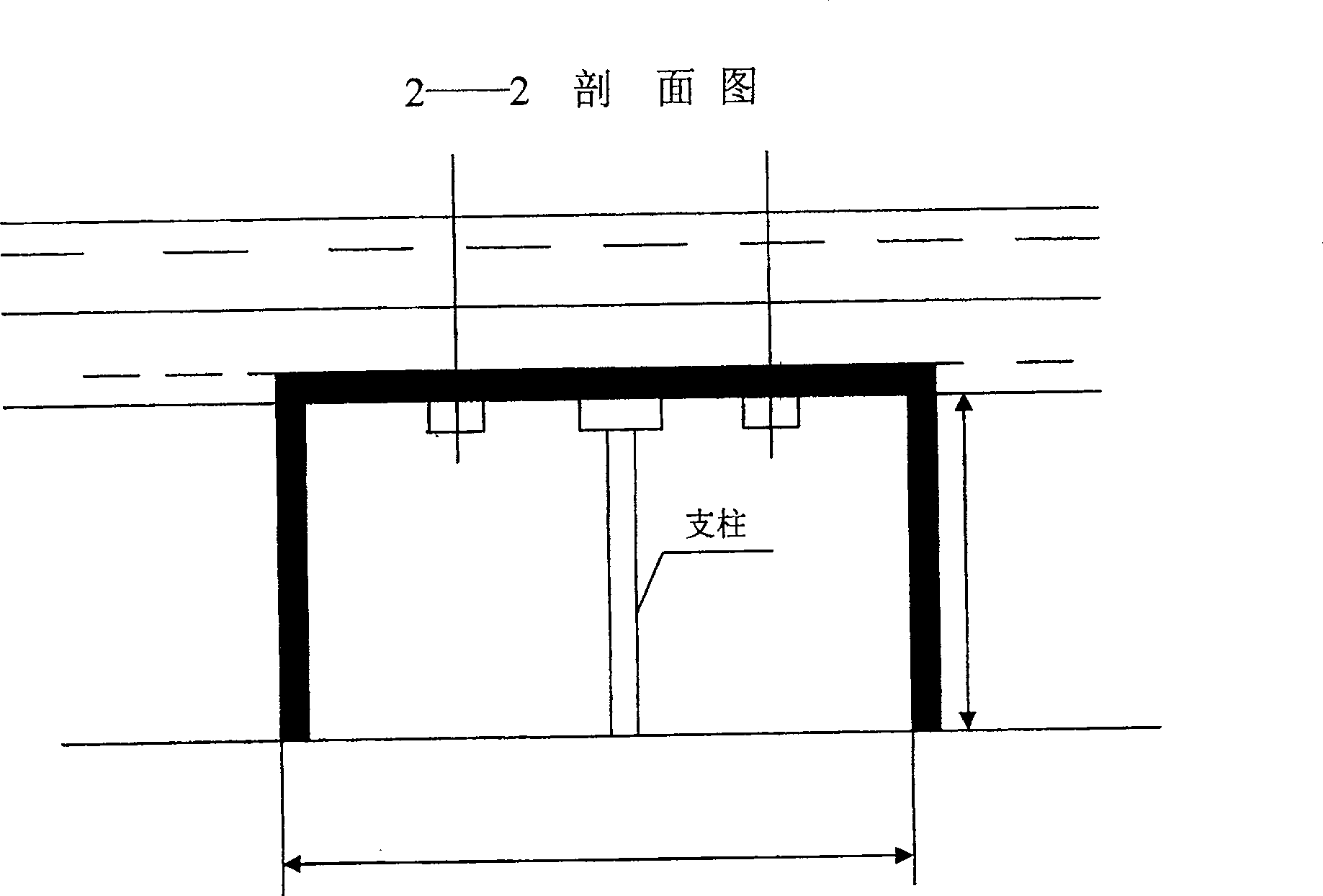

[0036] (2), hit the pillars: hit the pillars in the middle of the roadway after the bolt is hit; the pillars are th...

Embodiment 2

[0041] Embodiment 2: Geological overview of the coal mine: the average thickness of the coal seam is 2.2 meters, and the mining height is 2.2 meters; the horizontal coal seam; low gas; the direct roof is hard sandstone, sandy shale; no false roof; no water spray.

[0042] The coal mining process of pillar mining recovery coal pillar includes the following steps:

[0043] (1), hit the bolt; (2), hit the pillar; (3), drop the coal; (4), hit the bolt again; (5), load the coal, transport the coal; (6), return the pillar, put the roof and broken coal pillars;

[0044] (1) Bolting: firstly hit the bolt on the roof of the roadway that has been mined; hit the bolt for the bolter to hit the bolt. The distance between rows and columns between every two bolts is 1.0m, the length of the bolt is 2.2m, and the diameter of the bolt is 0.18m.

[0045] (2) Playing pillars: Playing pillars in the middle of the roadway after bolting; playing pillars is metal friction pillars. The distance bet...

Embodiment 3

[0050] Embodiment 3: Coal mine geology general situation: average thickness of coal seam is 4.2 meters, mining height is 3.8 meters; horizontal coal seam; low gas; direct roof is sandy mudstone, sandy shale; there is old roof; no watering.

[0051] The coal mining process of pillar mining recovery coal pillar includes the following steps:

[0052] (1), bolting; (2), pillars; (3), falling coal; (4), bolting again; (5), coal loading, coal transportation; (6) back column, caving and broken coal pillar;

[0053](1) Bolting: firstly hit the bolt on the roof of the roadway that has been mined; hit the bolt for the bolter to hit the bolt. The distance between rows and columns between every two anchors is 1.5m, the length of the anchors is 1.8m, and the diameter of the anchors is 0.16m.

[0054] (2), hit the pillars: hit the pillars in the middle of the roadway after the bolt is hit; the pillars are the wooden pillars. The diameter of the wooden pillar is 0.12m, and the distance be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com