Automatic sensing and control method of friction stir welding trajectory for fillet joints

A technology of friction stir welding and fillet joints, which is applied to welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve the problems of small structural parts, scratched welding plates, and small contact area, so as to improve welding production efficiency and reduce The possibility of scratching the welding plate, the effect of reducing the sliding friction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing, the present invention will be further described

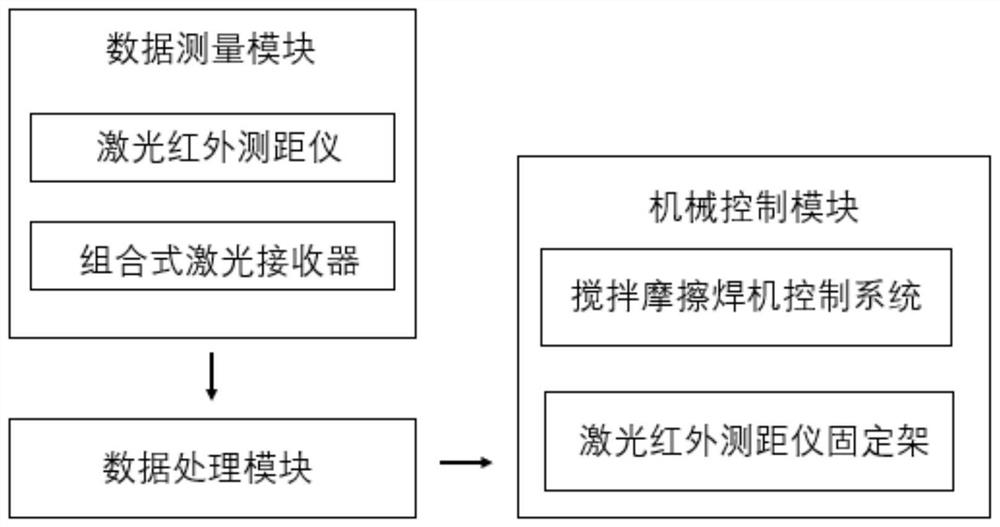

[0035] The method of the present invention utilizes as figure 1 The devices shown are:

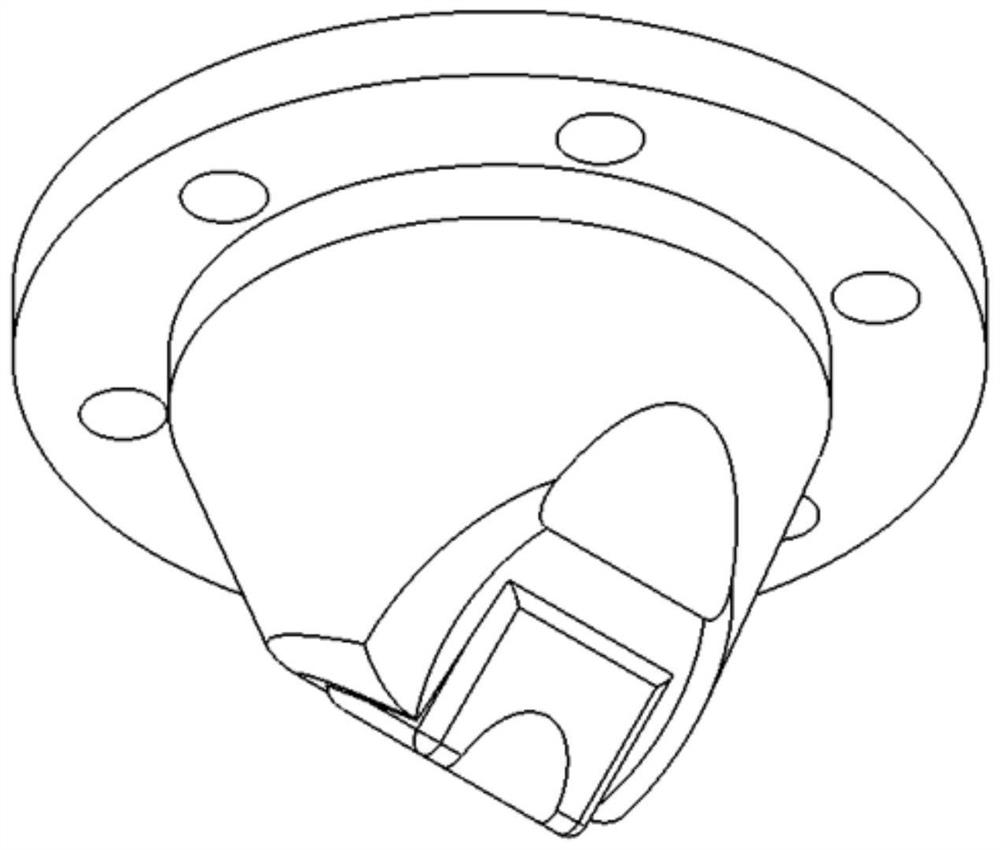

[0036]The data measurement module includes a laser infrared range finder, a laser receiver and a fixing frame, the laser infrared range finder and the laser receiver are used to measure the position change of the welding plate in real time, and send information to the data processing module; The frame is used to clamp a laser infrared rangefinder and a laser receiver above the welding plate; the data processing module is used to receive the measurement distance sent by the data measurement module in real time, and then make it according to the input in advance The parameter and algorithm obtain the distance that the stirring head needs to move up and down, and send the information to the mechanical control module; the mechanical control module is used to control the downward pressure o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com