Discharging claw

A material claw and shaft technology, applied in the field of unloading claws, can solve the problems of production line shutdown, increase of galvanized wire processing cost, high labor intensity, etc., and achieve the effect of continuous wire collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

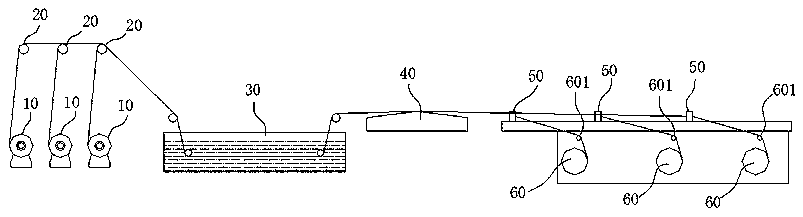

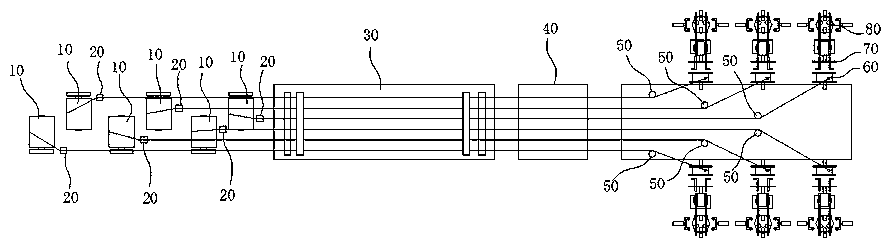

[0032] Such as figure 1 , 2 Shown, a kind of galvanized wire production system comprises the discharging device 10 arranged in sequence, the upstream guiding device 20, the electroplating tank 30, the downstream guiding device 50, and the unloading device; The discharging device 10 is used for raw material wire Released to the downstream of the production line, the upstream guiding device 20 is used to guide the raw material wire output from the feeding device 10 into the electroplating tank 30, and the electroplating tank 30 is used to electroplate the raw material wire, and the downstream guiding device 50 uses The galvanized wire output from the electroplating tank 30 is transported to the unloading device, and the unloading device is used for winding and collecting the galvanized wire.

[0033] preferred, such as figure 1 , 2 As shown, the discharge device 10 includes a discharge roller, and a discharge drive motor for driving the discharge roller to rotate; the dischar...

Embodiment 2

[0057] A method for processing galvanized wire using the system shown in embodiment 1, comprising the steps:

[0058] Step 1: Place the raw material wire on the galvanizing production line, and manually pull the raw material wire to the end of the production line;

[0059] Step 2: inject electrolyte solution into the electroplating tank 30 of the production line, and start the production line;

[0060] Step 3: After the production line has been running for a period of time, cut and recycle the raw material wire and the initial galvanized wire at the discharge end of the production line; then wind the galvanized wire on the unloading device to collect the galvanized wire;

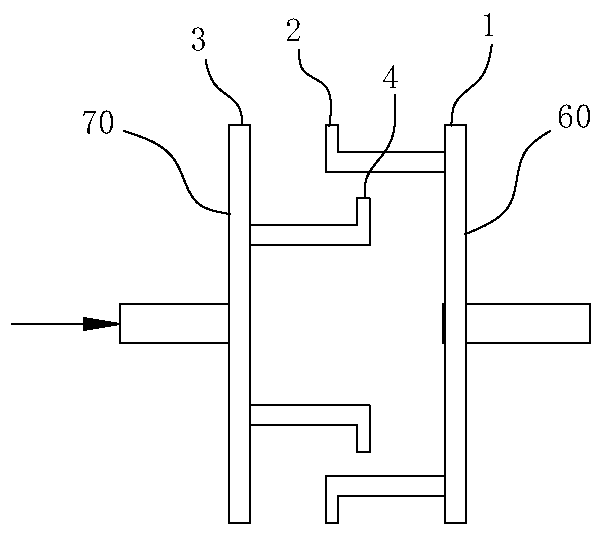

[0061] Step 4: After the galvanized wire on the wire winding roller 60 is wound to a preset length or number of turns, use the unloading claw 70 to unload the galvanized wire coil from the wire winding roller 60, and unload the unloading claw 70 Cut the galvanized wire between the winding roller 60, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com