A method for large-scale production and application of anaerobic granular sludge

An anaerobic granular sludge and granular sludge technology, which is applied in the direction of anaerobic digestion and treatment, can solve the problems of synchronously realizing the improvement of methane production efficiency and the difficulty of large-scale cultivation of anaerobic granular sludge, so as to achieve methane production efficiency, The effect of promoting the improvement of methane production efficiency and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

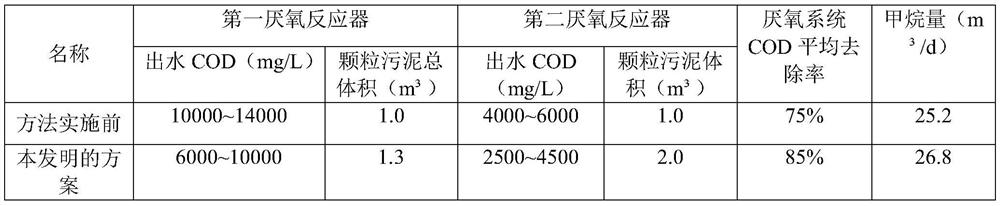

[0038] In this example, two anaerobic reactors (UASB small test device) are used to process high-concentration organic wastewater, and the treatment scale is 0.2m 3 / h, the effective volume of the reactor is 4m 3 , the COD concentration of the reactor influent is 20000mg / L, the pH value is 6.5, the sludge load is 0.8kgCOD / kgVSS·d, the rising flow rate is 2m / h, the temperature in the reactor is 38±2℃, and the two anaerobic reactors have Mature anaerobic granular sludge A is formed, and the volume of granular sludge is 1.0m 3 ; The effluent COD concentration of the two anaerobic reactors before treatment is 10000-14000mg / L, the average COD removal rate is 75%, and the effluent pH value is 6.8.

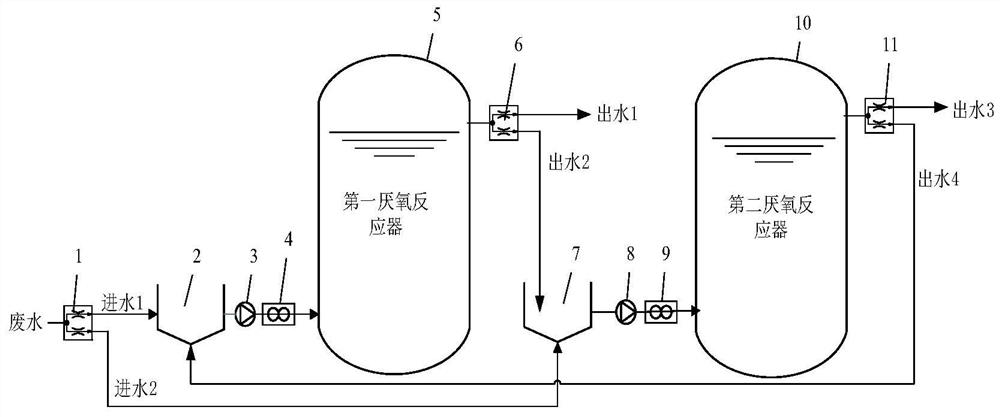

[0039] Use the above two reactors to form a wastewater treatment system, such as figure 1 As shown, the system includes an influent separator 1, a first anaerobic reactor 5, a second anaerobic reactor 10, a first intermediate tank 2, a second intermediate tank 7, a first inlet pump 3 a...

Embodiment 2

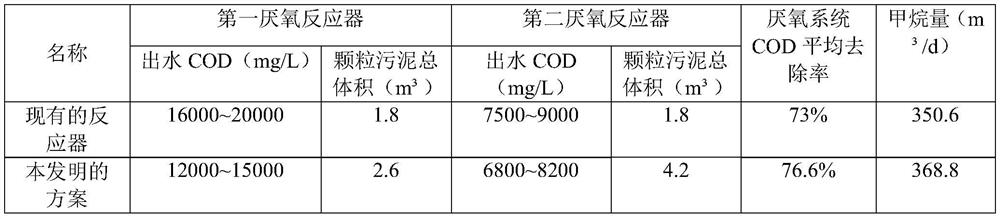

[0056] Aiming at the treatment of high-concentration organic wastewater in a pharmaceutical company, the existing pilot plant has a treatment scale of 2m 3 / h, the anaerobic system consists of two UASB reactors, and the effective volume of a single anaerobic reactor is 6m 3 , the system has been running continuously and stably for one year, and mature anaerobic granular sludge A has been formed in both reactors. The influent COD concentration of the existing two anaerobic reactor systems is 16000-20000 mg / L, the effluent COD concentration is 7500-9000 mg / L, and the effluent pH value is 7.2-7.8.

[0057] Above-mentioned reactor is formed anaerobic system according to the mode of embodiment 1, takes the following steps to process:

[0058] (1) Control the rising speed of the water flow in the second anaerobic reactor 10 to 5-8m / h, and disintegrate the mature granular sludge A in the second anaerobic reactor through closed circulation for 5-10 hours, and add 0.3-0.5 mg / L cation...

Embodiment 3

[0068] The high-concentration organic wastewater produced by a Chinese medicine production enterprise adopts the technical solution provided by the present invention. The anaerobic system is composed of two UASB reactors, and the effective volume of a single anaerobic reactor is 300m 3 , the wastewater treatment capacity is 10m 3 / h, the COD concentration of wastewater is 12000mg / L, and the pH value is 6.2.

[0069] Above-mentioned reactor is formed anaerobic system according to the mode of embodiment 1, takes the following steps to process:

[0070] (1) Control the rising speed of the water flow in the second anaerobic reactor 10 to be 5-8m / h, and disintegrate the mature granular sludge A in the second anaerobic reactor 10 through closed circulation for 5-10h, and add 0.3-8m / h Cationic polyacrylamide of 0.5 mg / L and composite conductive medium with effective volume of 0.05% to 1% of the reactor are added for 10 to 30 minutes to prepare sclerotium; the preparation method and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com