Full-automatic assembling equipment for connector inserting pieces

An assembly equipment, fully automatic technology, applied in the assembly/disassembly of contacts, manufacturing of contacts, etc., can solve problems such as high cost, unstable product quality, affecting use, etc., to improve assembly quality and efficiency, and good market application. effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

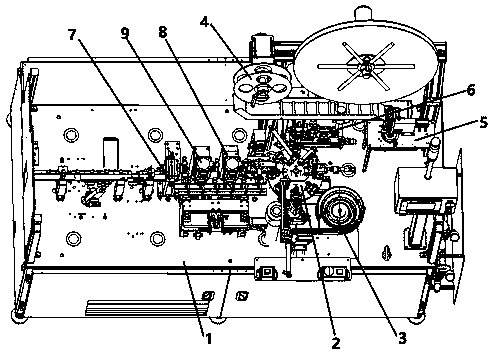

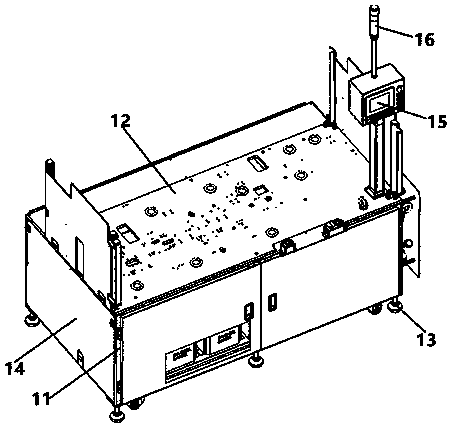

Method used

Image

Examples

Embodiment 2

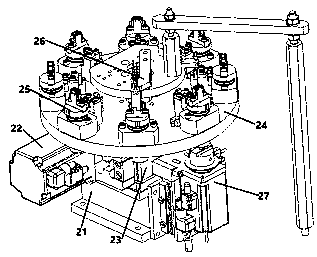

[0015] Embodiment 2, the difference between embodiment 2 and embodiment 1 is that the assembly pressing mechanism 65 is directly arranged above the jig rotation assembly 27, and at this time, there is no need to set the assembly pulling mechanism 64 in the insert assembly device 6, The device structure can be simplified.

[0016] Compared with the prior art, the beneficial effect is that, by adopting the above scheme, the present invention automatically bends the inserts being transported through the conveying bending device, and automatically assembles the bent inserts on the plastic parts through the insert assembly device, The product is conveyed through the indexing and rotating device and the conveying and dialing device, and the redundant insert is cut off by the insert shearing device, and the waste is sent away. The invention reduces manual participation, and fully automates the bending, assembly, and assembly of the insert. Compaction and shearing improve the assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com