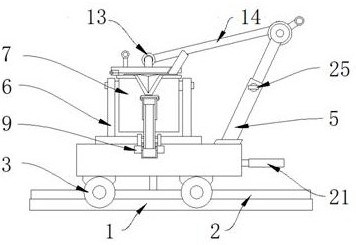

A sand mold rail casting device

A rail-type, casting-mold technology, applied in the control of pouring molten metal from the ladle, casting equipment, casting molten material containers, etc., can solve problems such as waste of manpower and safety hazards, and achieve increased safety, ease of movement, and positioning. The effect of convenient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

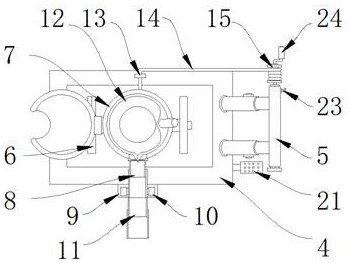

Embodiment 2

[0033] refer to Figure 8-10 , and the difference from Example 1 is that the sand mold rail-type pouring device also includes a positioning rail 2, the bottom of the pouring car is provided with a positioning device for fixing the position of the pouring car on the bottom rail 1, and the positioning device and the positioning rail 2 cooperate to achieve Positioning function, the positioning device includes a positioning cavity 16 arranged inside the vehicle floor 4 and a number of positioning holes 17 on the upper surface of the positioning rail 2. The positioning cavity 16 is provided with a positioning column 18 that can move vertically up and down and can be inserted into the positioning hole 17. The positioning column 18 Magnetic blocks 19 are respectively provided on the top and surface of the positioning chamber 16. The inner top wall and the inner bottom wall of the positioning cavity 16 are all embedded with iron blocks 20 magnetically adsorbed to the magnetic block 19....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com