A material delivery system and delivery method thereof

A material and conveying vehicle technology, which is applied in the direction of casting molten material containers, manufacturing tools, casting equipment, etc., can solve the problems of resource waste and low resource utilization rate, and achieve the effect of reducing waste, reducing the amount of use, and improving resource utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The application will be described in further detail below in conjunction with all the accompanying drawings.

[0046] The processing equipment in this embodiment can be an automatic die-casting machine.

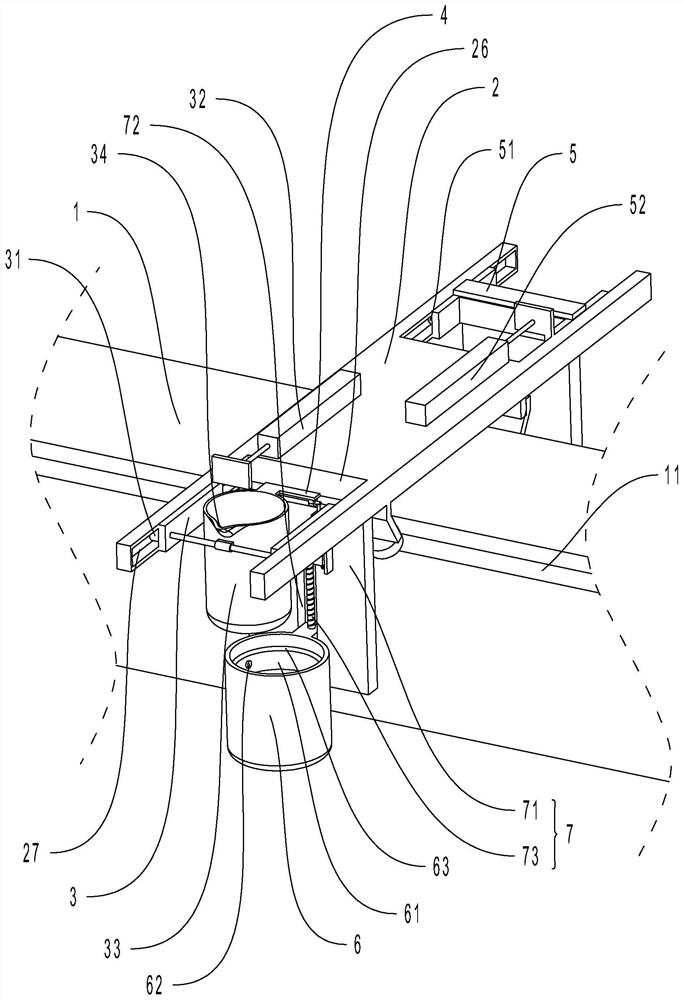

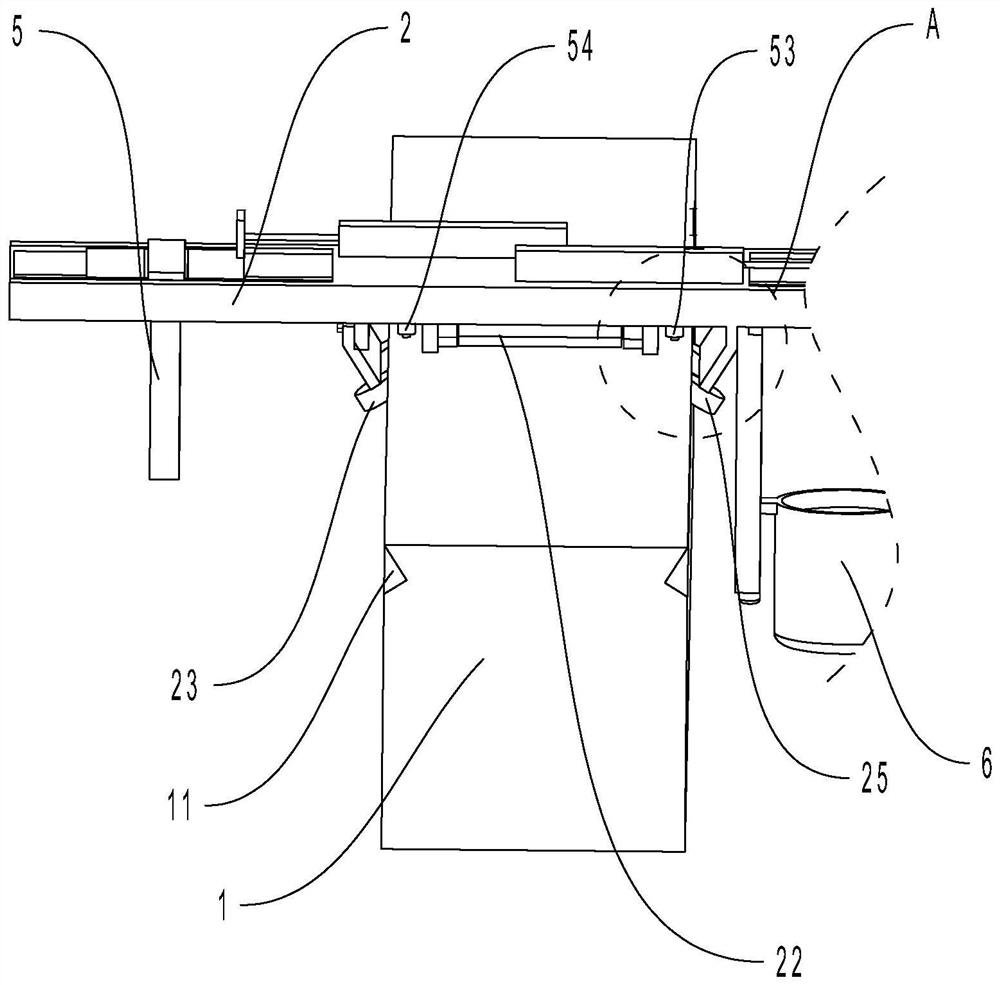

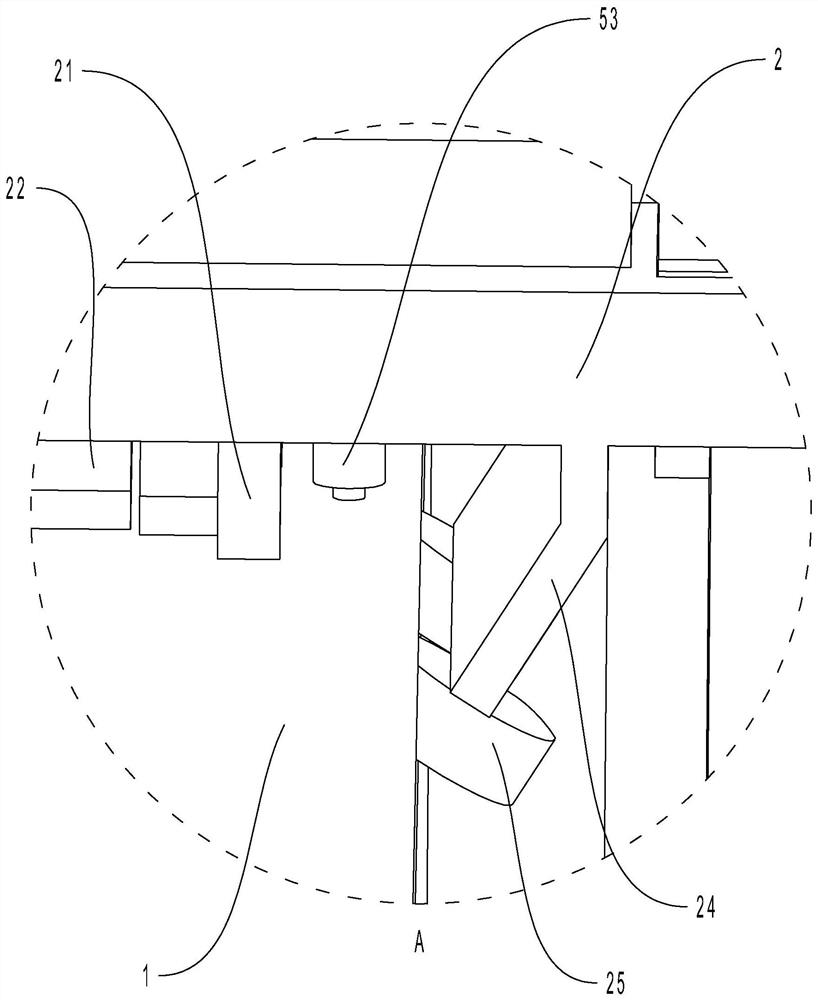

[0047] The embodiment of the present application discloses a material distribution system. refer tofigure 1 , figure 2 , the material distribution system includes a guide rail 1, a transport vehicle 2 slidingly connected to the guide rail 1, a driving mechanism 22 arranged on the guide rail 1 to drive the transport vehicle 2 to slide, a sliding seat 3 slidingly connected to the transport vehicle 2, and a sliding seat 3 Rotatingly connected hopper 33 and a discharge mechanism connected to the hot melting furnace for putting molten metal into the hopper 33, and the sliding seat 3 is provided with a rotating assembly 4 that drives the hopper 33 to rotate.

[0048] The hot melting furnace is set on one side of the guide rail 1, and the discharging mechanism puts the mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com