A kind of demoulding method of concrete pouring sample

A concrete and pouring mold technology, which is applied in the field of construction engineering, can solve problems such as air hole blockage, test piece performance changes, and difficulty in demoulding, and achieve the effects of preventing hole blockage, low failure rate, and preventing concrete quality from being affected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, realization goals and use functions of the present invention more clear and intuitive, the present invention will be explained in detail below in conjunction with specific embodiments.

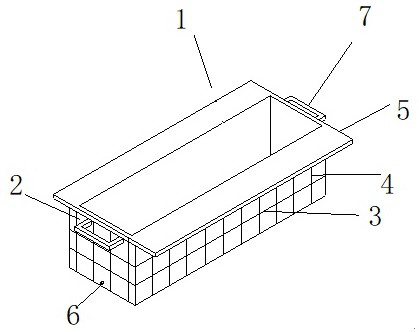

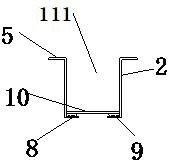

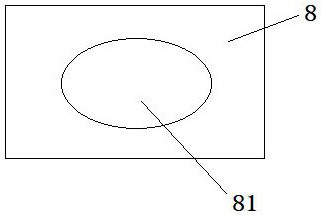

[0025] Please refer to the attached Figure 1~6 , The invention provides a concrete sample pouring mold and a matching sample demoulding device. A concrete sample pouring mold structure as attached Figure 1~3 . The pouring mold 1 is provided with a sample chamber 111 with an upward opening surrounded by four templates 2 and a bottom plate 8 . Lateral stiffeners 3 and vertical stiffeners 4 are installed in the horizontal and vertical directions on the outer wall of the template 2 to enhance the mechanical strength of the formed chamber. The top edge of the long side of the sample chamber 111 is provided with a constraining edge 5 that is turned outwards for demoulding and fixing. The formwork 2, bottom plate 8, transverse stif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com