Preparation method of hot-dip galvanized sheet, and hot-dip galvanized sheet

A technology of hot-dip galvanized sheet and hot-dip galvanizing, which is applied in the direction of heat treatment equipment, hot-dip galvanizing process, heat treatment process control, etc., can solve the problems of affecting product yield and cost increase, and achieve the elimination of mixed crystal defects and good matching , simple and easy-to-implement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

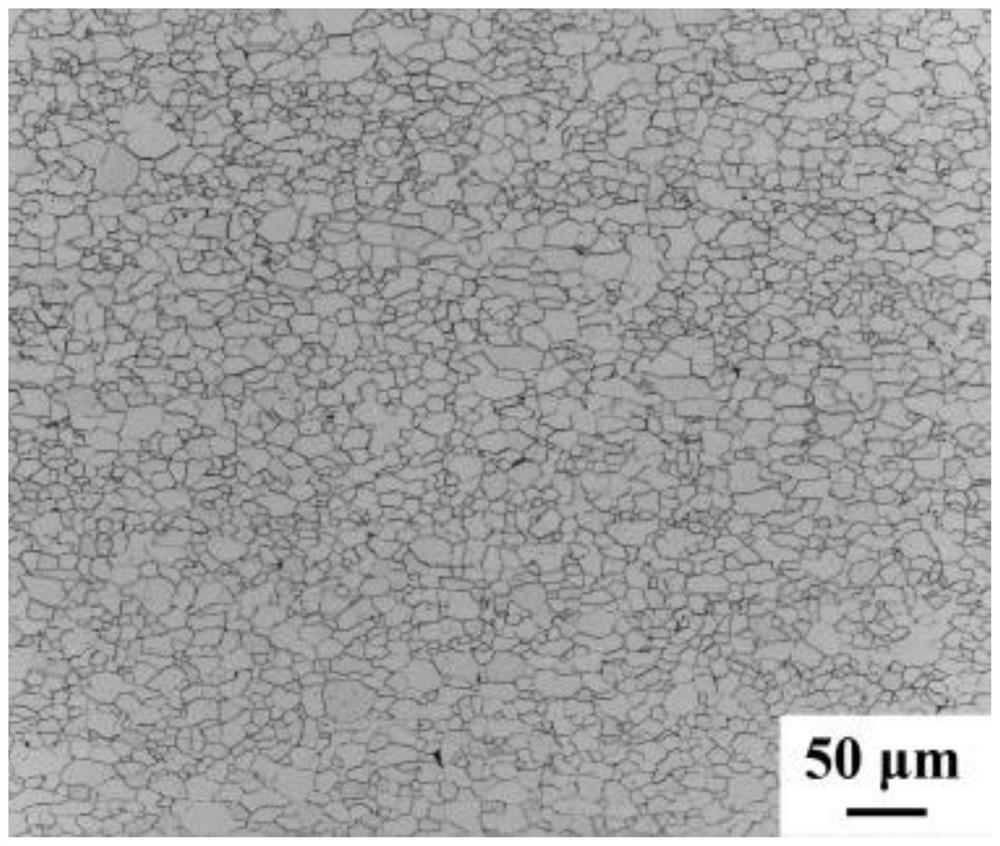

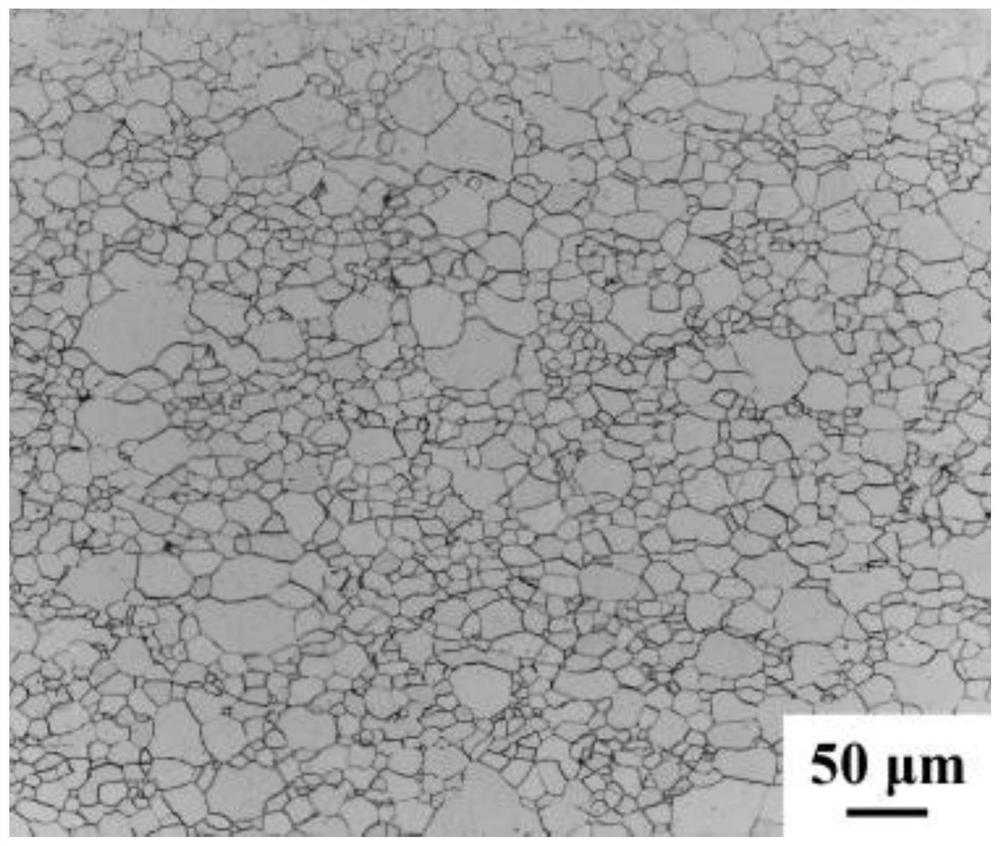

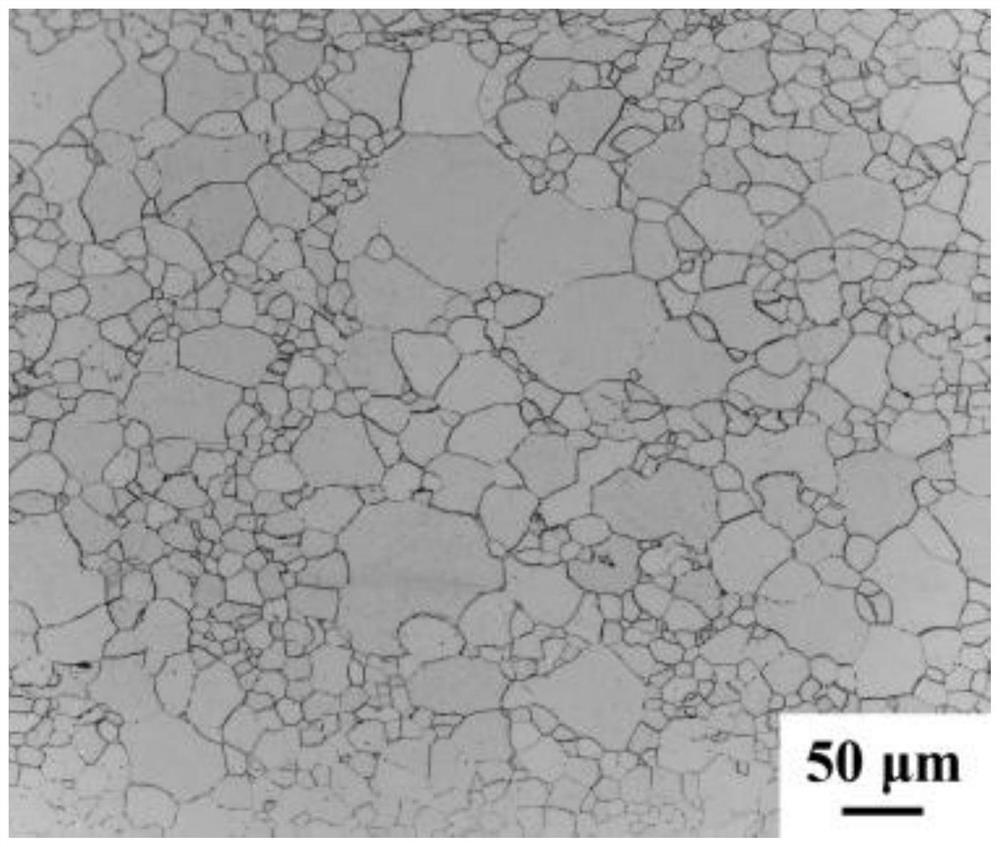

[0045] Generally speaking, the preparation method includes: according to the parameters of the cold-rolled strip, query the target annealing temperature T0 of the annealing furnace used in the annealing process, and the target strip running speed U0 of the annealing furnace; adjust the When the strip running speed U of the annealing furnace changes from the state satisfying U0-Ub≤U≤U0+Ua to satisfying U

[0046] That is, when the running speed U of the strip steel satisfies U0-Ub≤U≤U0+Ua, the annealing temperature T=T0 is controlled, and it is determined through research that the microstructure and grain size uniformity of the hot-dip galvanized sheet obtained is good; and when the When the strip running speed U is adjusted downward to be below U0-Ub, the annealing temperature T<T0 is regulated synchronously, and by contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com