Control method for balancing sintering air volume

A control method and air volume technology, which is applied to the furnace control device, furnace type, furnace, etc., can solve the problems of changing local wind resistance, main pipe negative pressure, air volume influence, heat removal in high temperature areas, etc., to achieve balanced control and reduce inefficiencies The effect of air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings, through the description of the embodiments, to help those skilled in the art to have a more complete, accurate and in-depth understanding of the inventive concept and technical solutions of the present invention.

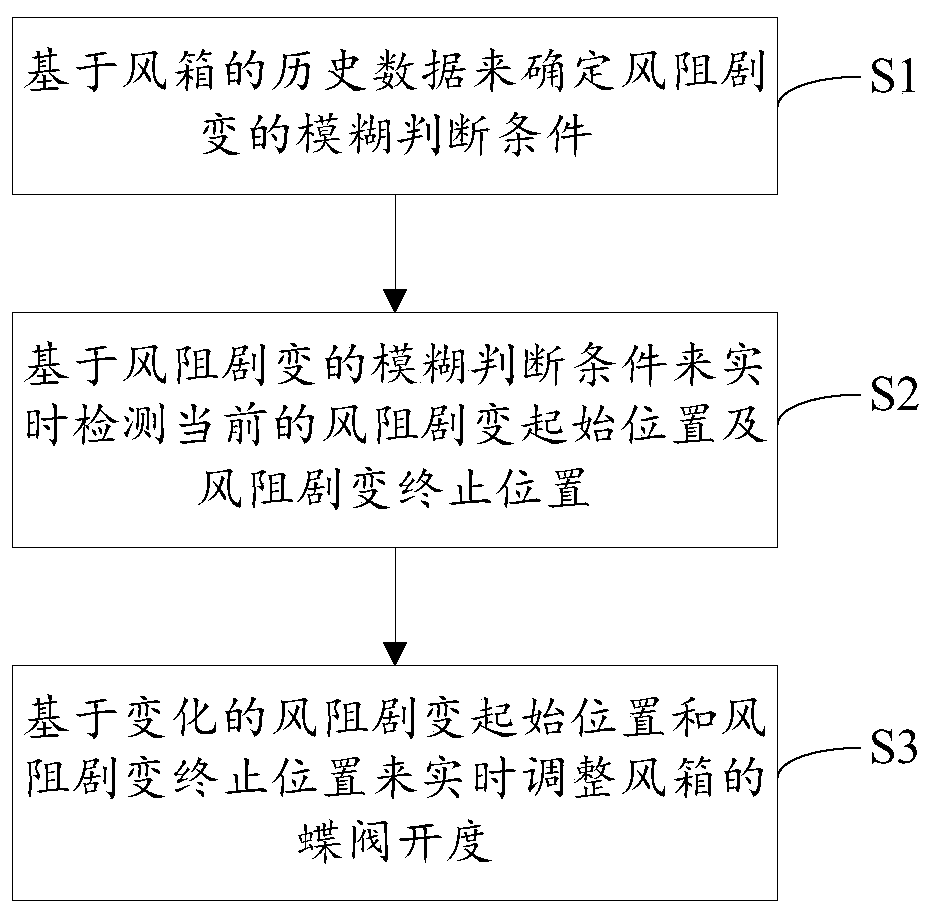

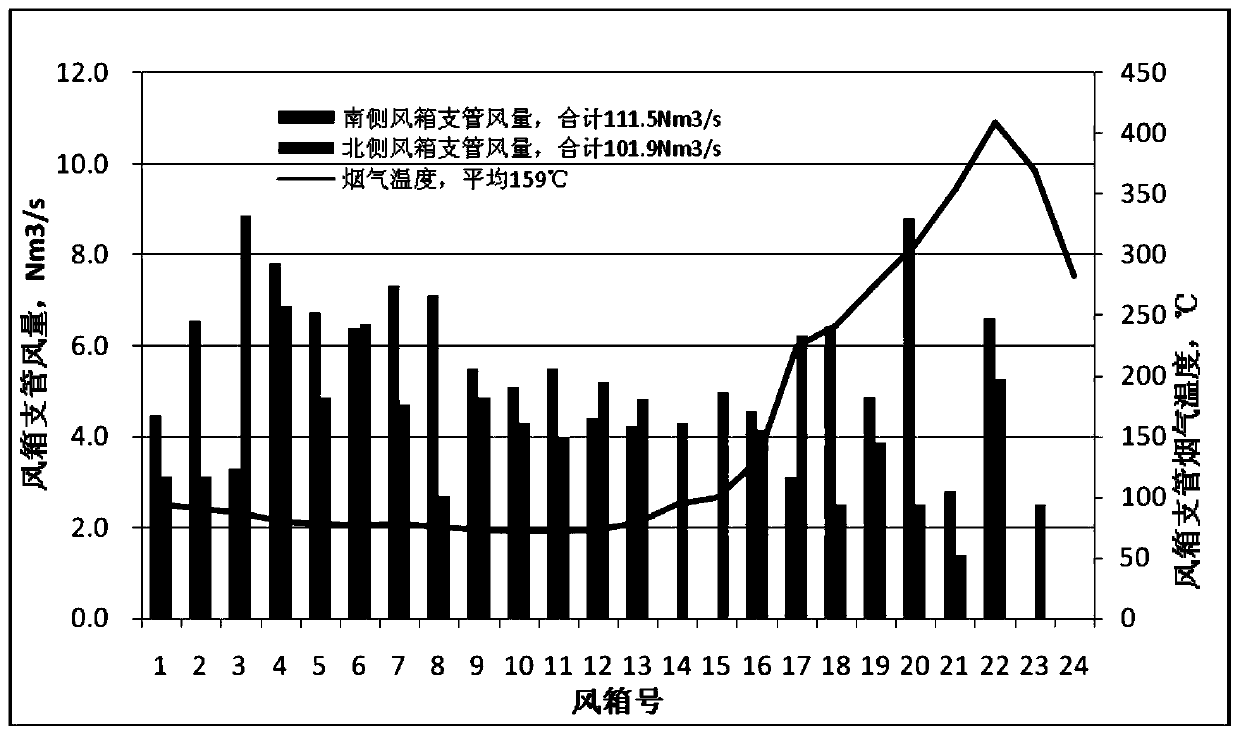

[0027] The invention automatically tracks the drastic change position of wind resistance, and gives the recommended differential pressure value of this position relative to the main pipe according to the historical data of the bellows, finds out the appropriate opening degree of the butterfly valve of the bellows as the target opening degree of the butterfly valve, and the target butterfly valve opening degree based on the drastic change of wind resistance is real-time. Adjust the butterfly valve of the subsequent bellows, dynamically adjust the opening of each bellows butterfly valve, dynamically adjust the air volume of each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com