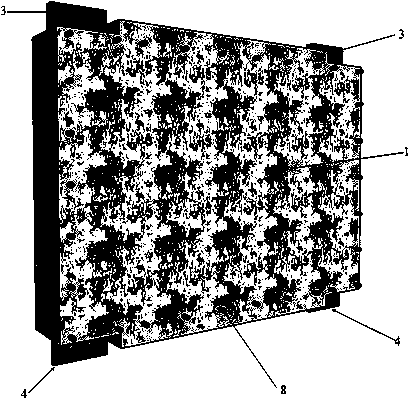

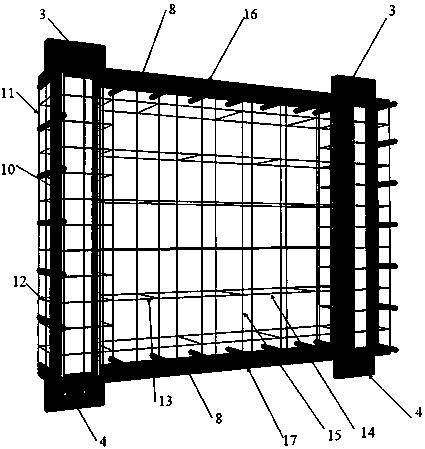

Prefabricated stiffness concrete shear wall plate with steel beam connecting keys, assembled stiffness concrete shear wall and manufacturing method

A concrete shear wall and connection key technology, which is applied in the field of prefabricated stiffened concrete shear wall, prefabricated stiffened concrete shear wall and its production, and assembled stiffened concrete shear wall, can solve the constraints of assembled shear wall The use of force wall structure can not reflect the advantages of shear wall structure, and the connection quality is difficult to control and guarantee, so as to achieve the effect of simple connection method, high bearing capacity and rigidity, and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the embodiments of the present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

[0051] In describing the present invention, it is to be understood that the terms "comprises / comprising", "consisting of" or any other variation thereof are intended to cover a non-exclusive inclusion such that a product, device, A process or method includes not only those elements, but may also include other elements not expressly listed, or elements inherent in such a product, apparatus, process, or method, as required. Without further limitations, an element defined by the phrase "comprising / comprising...", "consisting of... does not exclude the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com