Brush disc structure and cleaning robot

A technology for cleaning robots and brushing disks, applied in cleaning machinery, robot cleaning machines, cleaning equipment, etc., can solve the problem of small operation space, difficult operation, and difficulty in directly observing the card connection between the brushing disk and the bottom of the cleaning robot. Position and other issues to achieve the effect of improving the docking accuracy and simplifying the installation and disassembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

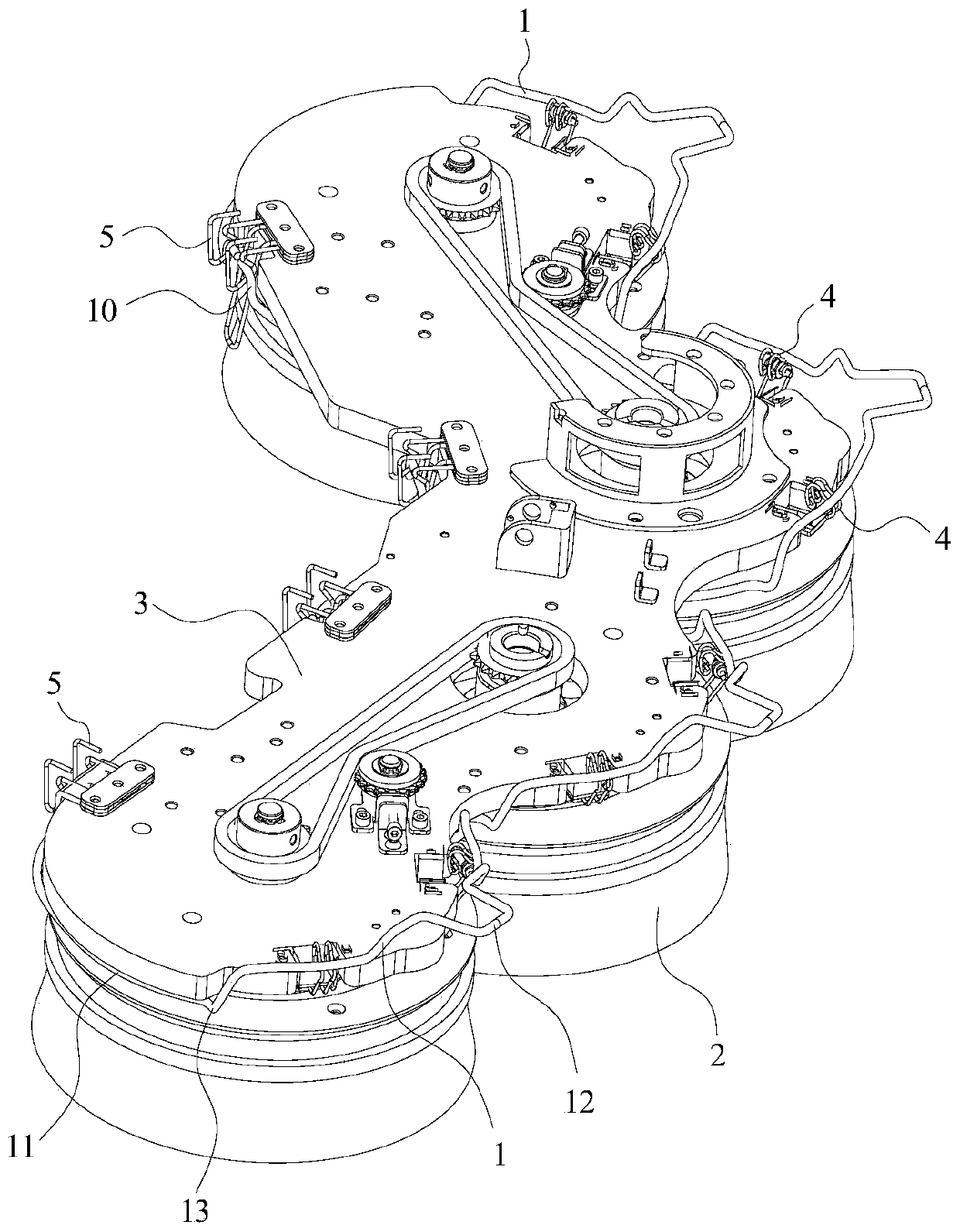

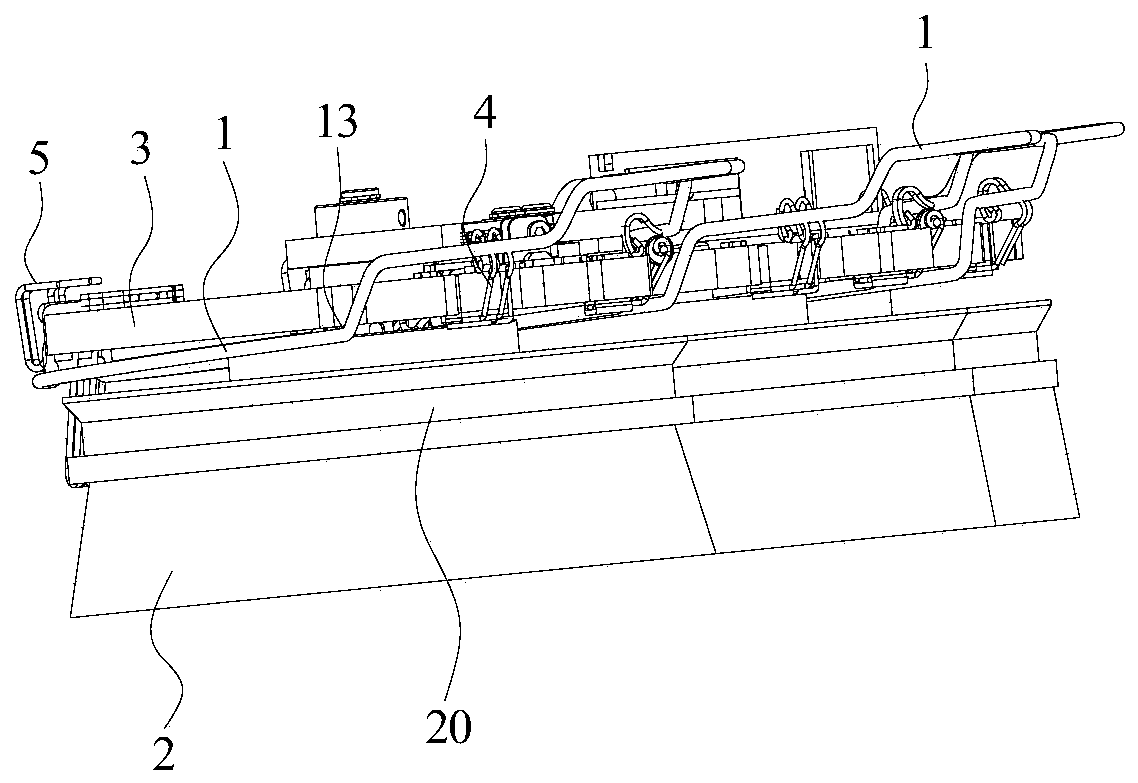

[0049] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the brush tray structure provided in this embodiment includes an installation and removal frame 1 and a brush tray 2, and the brush tray 2 can be clipped to the bottom of the cleaning robot. The installation and removal frame 1 is provided with a hinged part 10, and the hinged part 10 is hinged on the bottom of the cleaning robot. The installation and removal frame 1 can be connected with the brush plate 2, and the installation and removal frame 1 can be rotated with the hinge 10 as the rotation center to drive the brush plate 2 to be clamped on the bottom of the cleaning robot, or to drive the brush plate 2 from the bottom of the cleaning robot up and out.

[0050] When the brush tray 2 needs to be disassembled, first utilize the lifting mechanism on the cleaning robot to raise the brush tray 2, and leave an operation space for removing the brush tray 2 between the brush tray 2 and the ground. Then th...

Embodiment 2

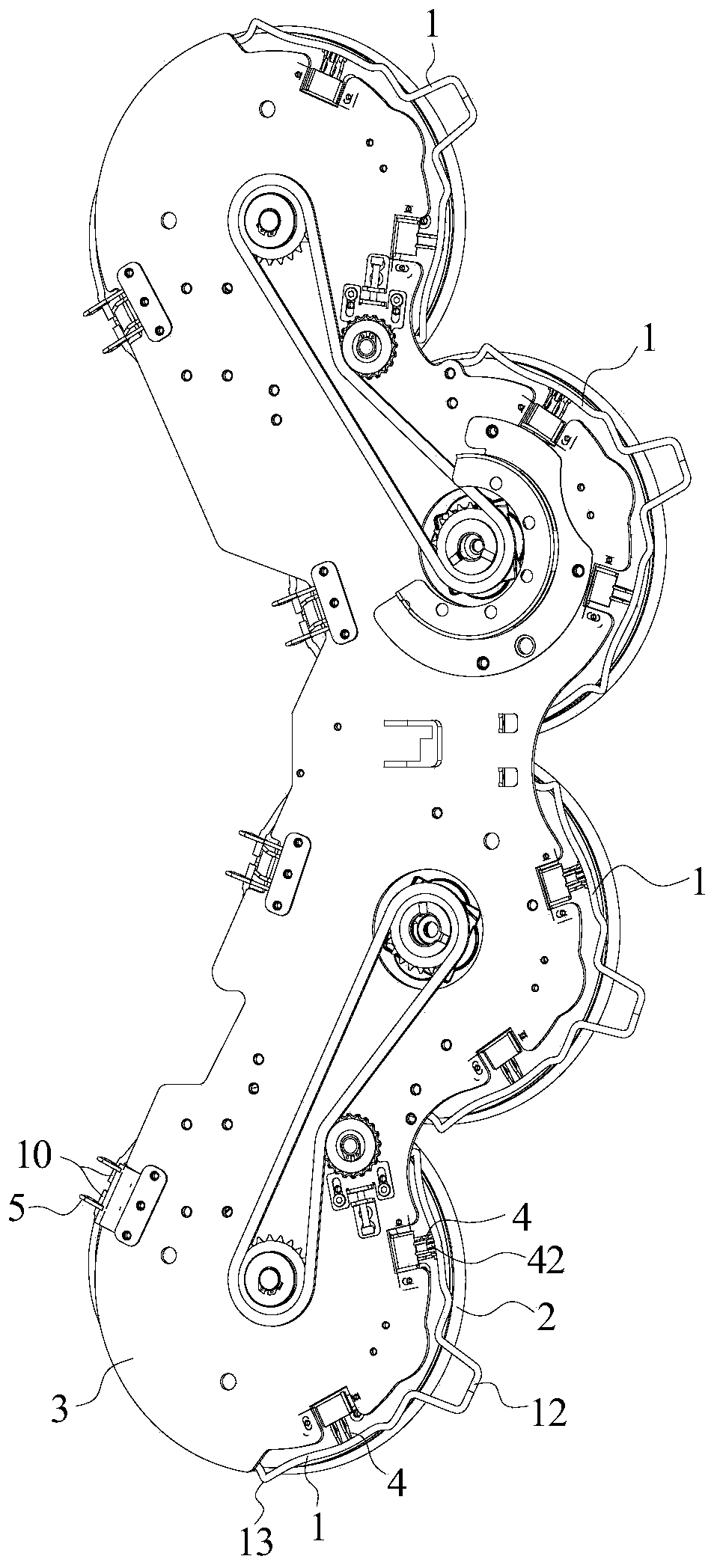

[0092] Such as Figure 7 As shown, the cleaning robot provided in this embodiment includes the brush plate structure in the first embodiment.

[0093] Further, such as Figure 7 As shown, the bottom of the cleaning robot is provided with a brush plate mounting plate 3 , and the brush plate 2 is clamped on the brush plate mounting plate 3 .

[0094] The cleaning robot provided in this embodiment includes the brush plate structure in the first embodiment, so the cleaning robot provided in this embodiment and the brush plate structure in the first embodiment can solve the same technical problems and achieve the same technical effect. The cleaning robot provided by this embodiment also alleviates the problem in the prior art that when the brush plate is installed and removed on the bottom of the cleaning robot, after the position where the bottom of the cleaning robot is engaged with the brush plate is raised, the distance between it and the ground The remaining operating space ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com