Method for integrally and transversely moving high and large formwork through high and large trolley

A technology of tall templates and trolleys, applied in earthwork drilling, wellbore lining, tunnel lining, etc., can solve the problems of cumbersome construction work, consumption, and reduced work efficiency, so as to reduce the use of mechanical equipment and manual labor, and facilitate installation and disassembly operations , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The embodiment of the present invention provides a method for using a tall trolley to traverse a tall formwork as a whole, including the following steps:

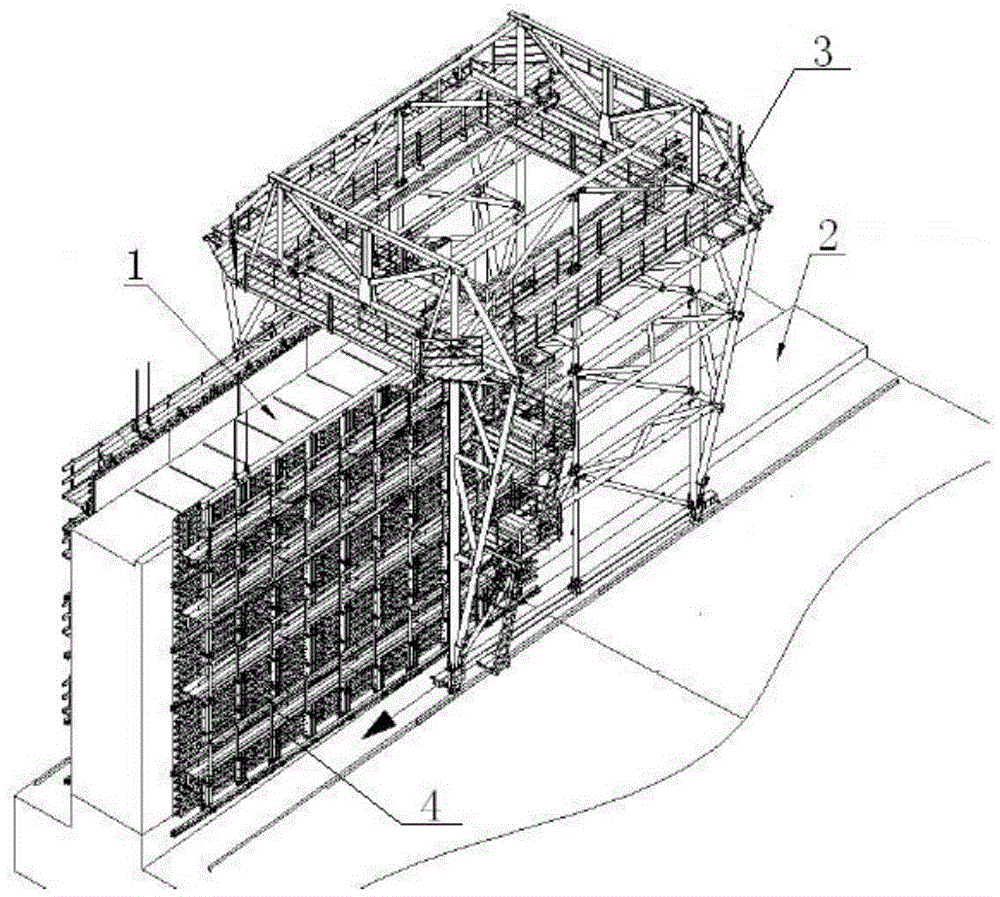

[0042] S1, such as figure 1 As shown, the slide rail is first installed on the tunnel floor, and the material of the slide rail is steel rail, and then the formwork is installed and reinforced on both sides of the wall of the first section of the tunnel. The formwork is the side formwork of the wall, and two The templates are arranged vertically and parallel to the wall, and then a trolley is installed on the slide rail of the bottom plate of the second section of the tunnel, and the trolley moves on the slide rail through the steel wheels at the bottom.

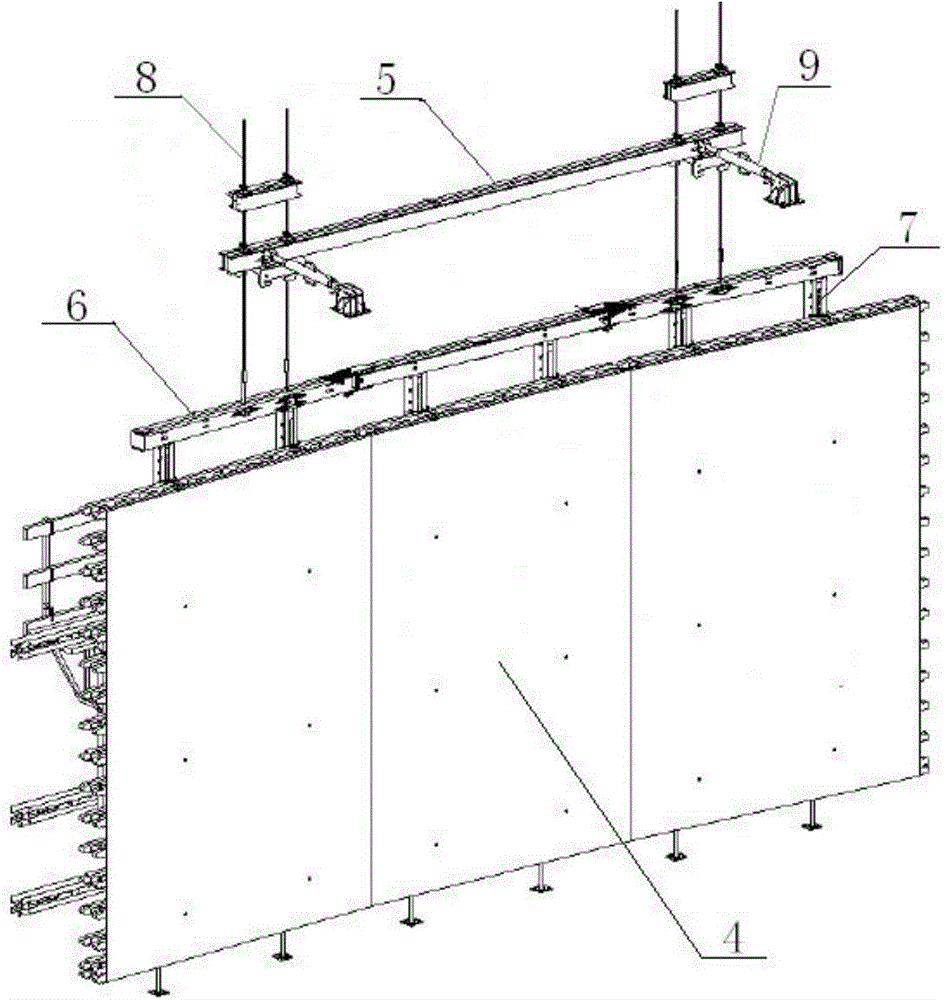

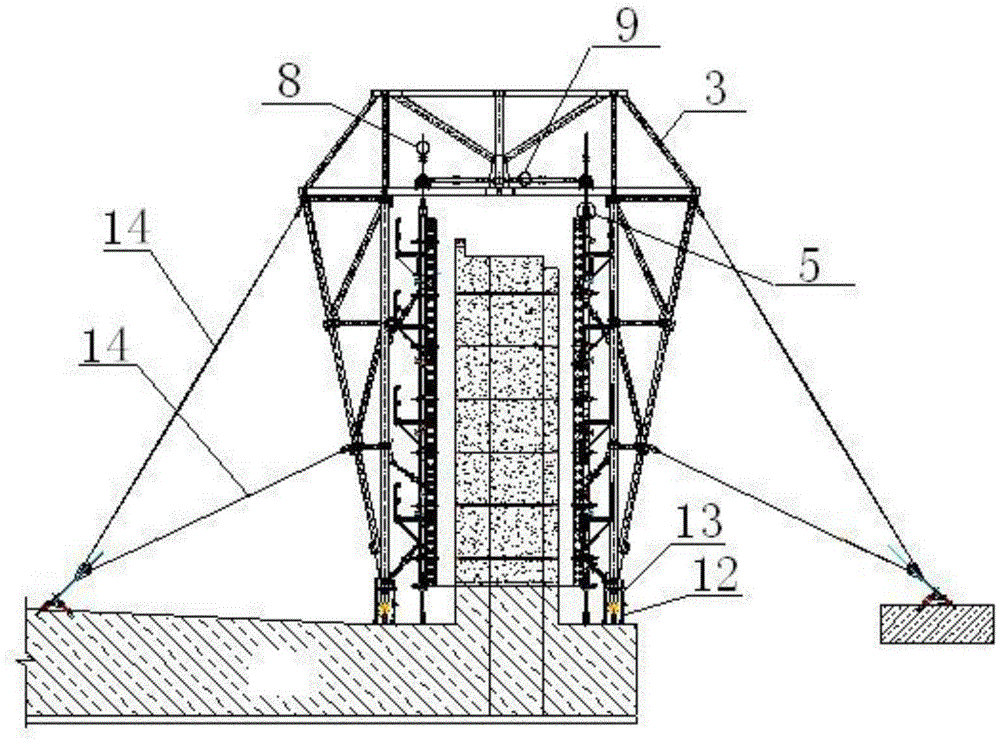

[0043] S2. Move the trolley to the first section of the tunnel through the slide rails. When the trolley completely covers the formwork, connect the trolley to the formwork, such as figure 2 , 3 As shown, the formwork is connected through the load-sharing beam a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com