New energy vehicle fuel cell storage device

A technology of new energy vehicles and fuel cells, which is applied in the direction of secondary batteries, battery pack components, and isolation of batteries from their environment. Avoid wear and other problems, achieve the effect of easy installation and disassembly, reduce frictional resistance, and avoid pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

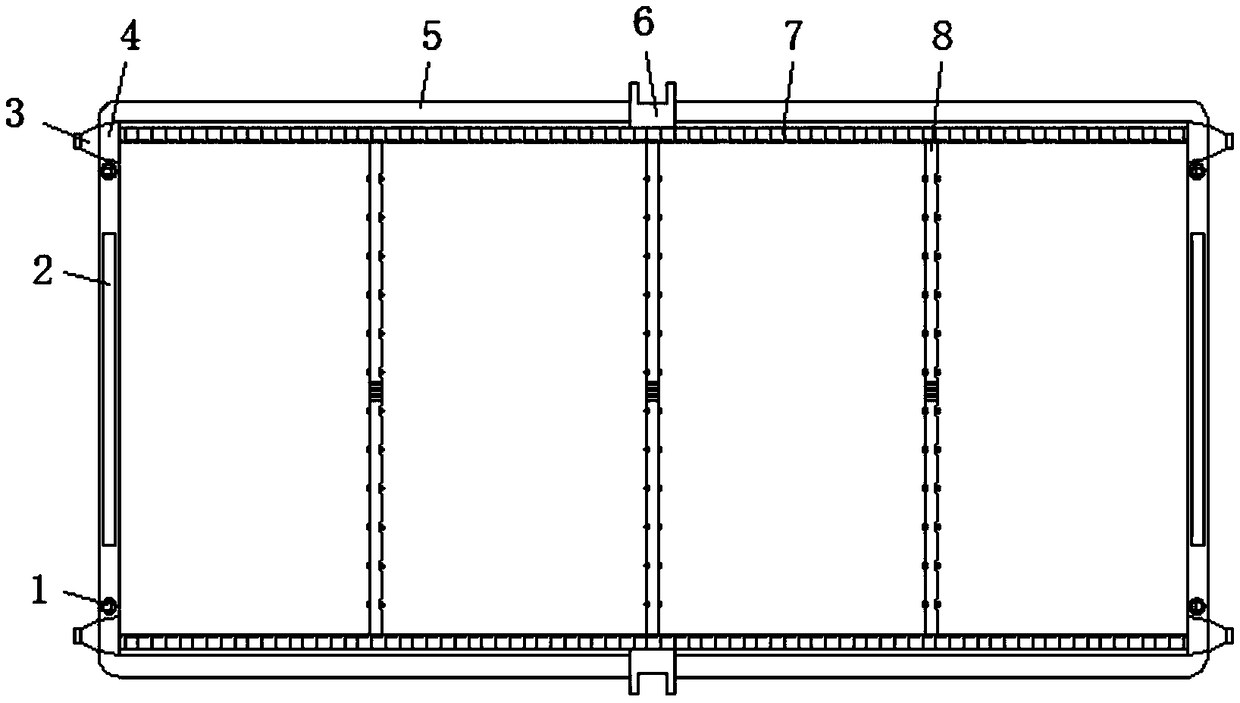

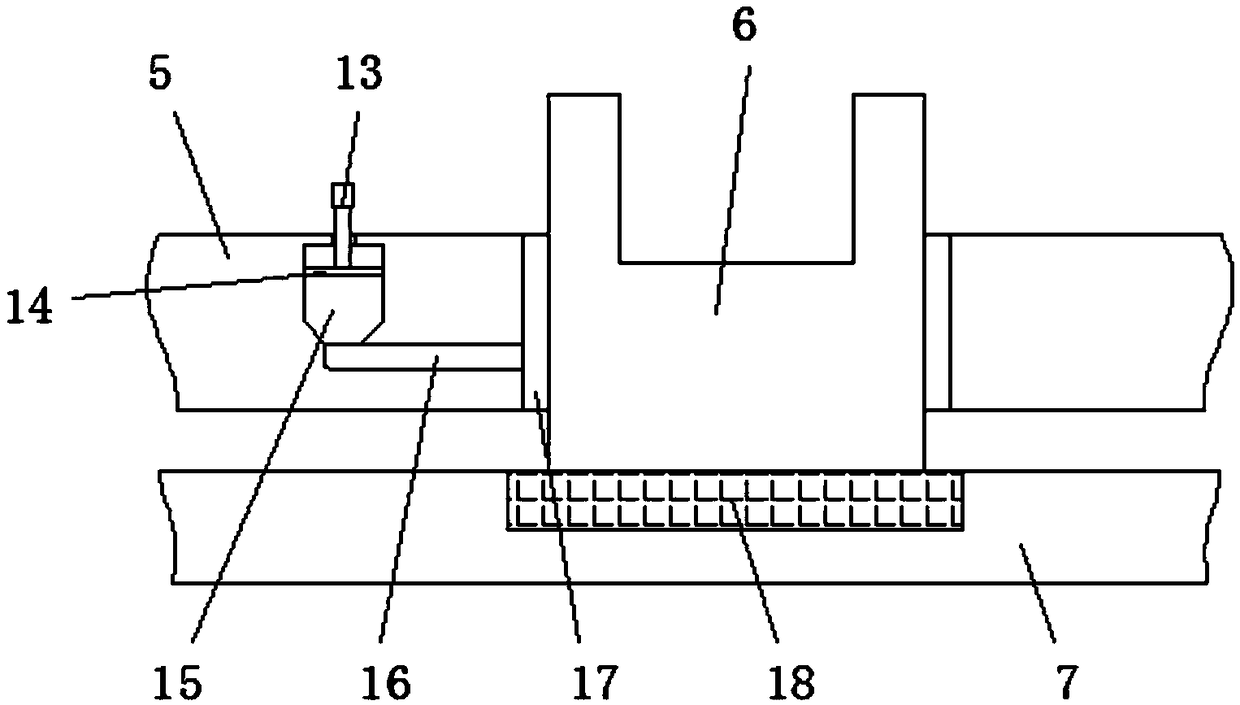

[0027] Embodiment one, with reference to figure 1 , image 3 and Figure 4 , a new energy vehicle fuel cell storage device, including a housing 5, a limiting groove 2 is opened at the center of the vertical end surfaces on both sides of the housing 5, and the vertical end surfaces on both sides of the housing 5 are located in the limiting groove 2 There are positioning grooves 1 on both sides symmetrically, the top of the housing 5 is clamped and fixed with the cover plate 20 through the positioning groove 1, the bottom of the housing 5 is clamped and fixed with the bottom plate 21 through the positioning groove 1, and the two sides of the housing 5 are horizontal A transmission rod 6 is threaded inside the end, and a pressure plate 7 is movably connected to the inner side of the transmission rod 6 , and a bearing 18 is arranged at the inner center of the pressure plate 7 and on the surface of the transmission rod 6 .

Embodiment 2

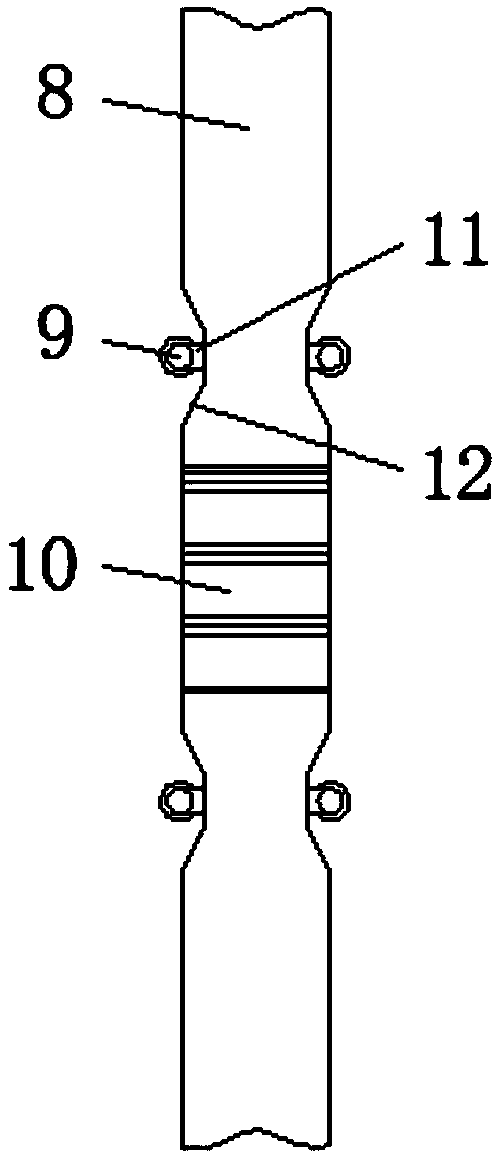

[0028] Embodiment two, refer to Figure 1-2 , the two pressure bearing plates 7 are connected by a partition plate 8, grooves 12 are symmetrically opened on both sides of the outer wall of the partition plate 8, and the inner surface wall of the vertical end of the groove 12 is welded with a connecting rod 11, connected The outer side of the rod 11 is rotatably connected with rollers 9, and the partition plate 8 with a parallel and equidistant structure can effectively separate the battery packs inside the casing 5, ensuring that the mutual independence between the battery packs is not affected, and at the same time, when the battery packs When the battery pack is embedded between the partition plates 8 to move, the rollers 9 will play a role of rolling friction on the outer walls of both sides of the battery pack, reducing the impact of frictional resistance when the battery pack moves, thereby facilitating the installation and disassembly of the battery pack .

Embodiment 3

[0029] Embodiment three, refer to figure 1 and Figure 4 , the opening end of the inner surface wall of the positioning groove 1 is provided with an elastic mesh cover 19, and the center of the surface of the elastic mesh cover 19 is provided with a round hole, the inner surfaces of the top plate 21 and the cover plate 20 and the positions corresponding to the positioning groove 1 are all The positioning post is welded, so that the cover plate 20 and the bottom plate 21 can fix the storage device as a whole through the mutual clamping of the positioning post and the positioning slot 1, and when the positioning post is embedded in the positioning slot 1, the positioning post will pass through the elastic net The circular hole on the surface of the cover 19, and extrudes the elastic mesh cover 19, so that the inner diameter of the circular hole on the surface of the elastic mesh cover 19 becomes larger, and then plays a role of sealing protection for the connection between the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com