Air-fuel ratio control method reflecting brake booster inflow flow rate

A technology of brake booster and air-fuel ratio, applied in the direction of brake, engine control, fuel injection control, etc., can solve problems such as preventing misfire, achieve stable air-fuel ratio control, suppress the occurrence of misfire, and reduce the problem of exhaust gas Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

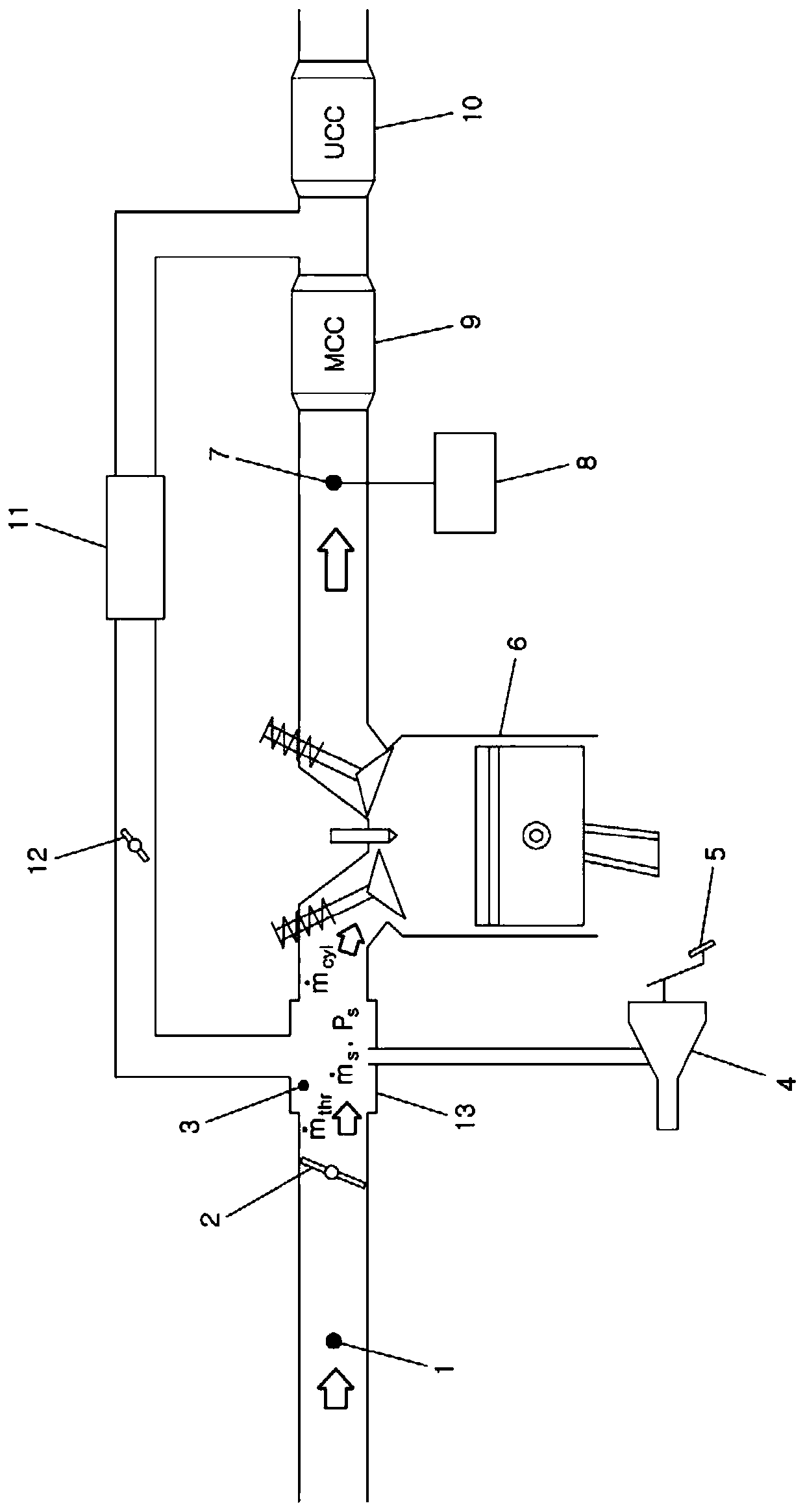

[0037] The following description is merely exemplary in nature and is not intended to limit the invention, application or uses. It should be understood that throughout the drawings, corresponding reference numerals indicate like or corresponding parts and features.

[0038] However, detailed descriptions of known functions and configurations that may unnecessarily obscure the subject matter of the present invention will be omitted.

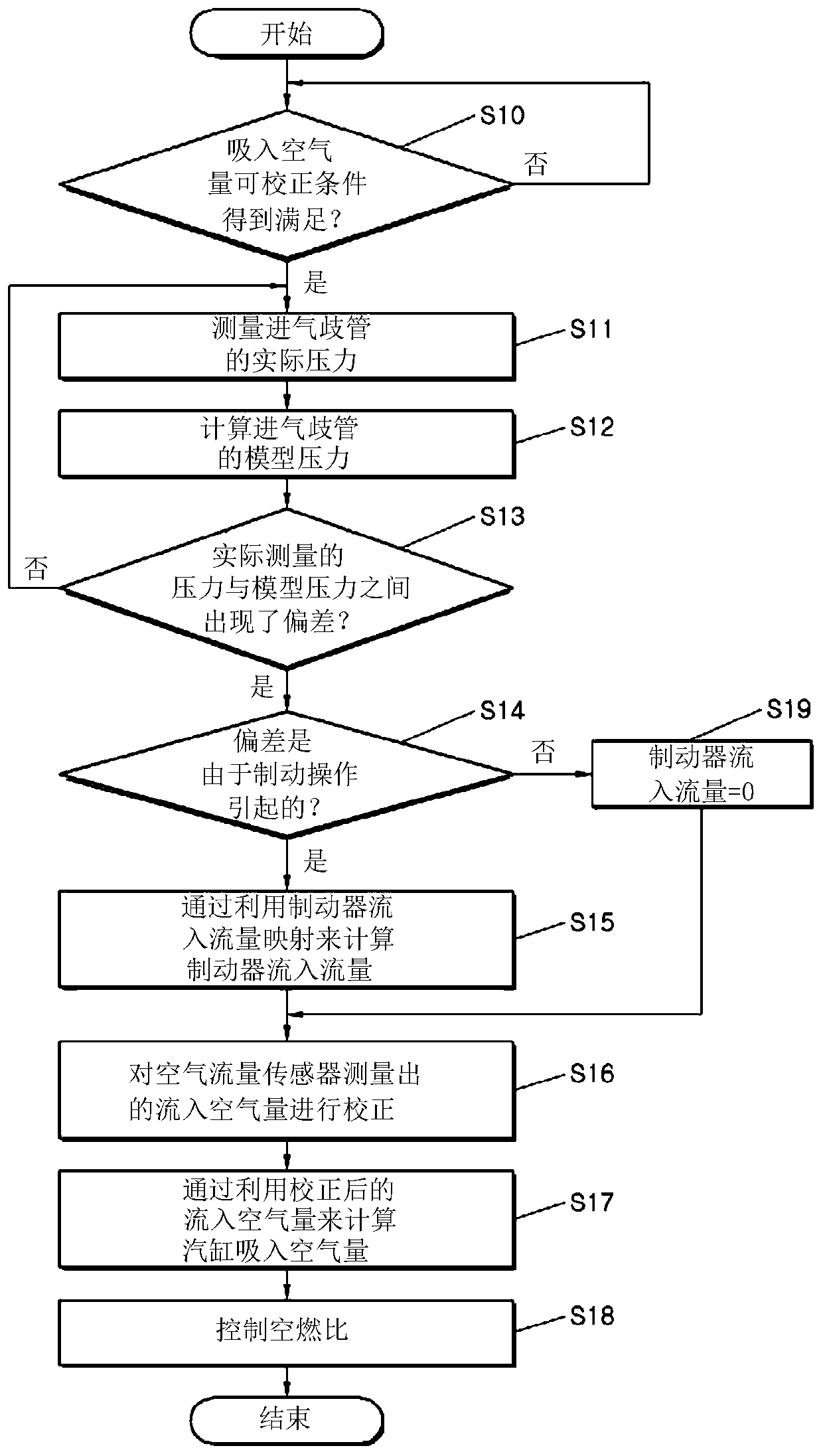

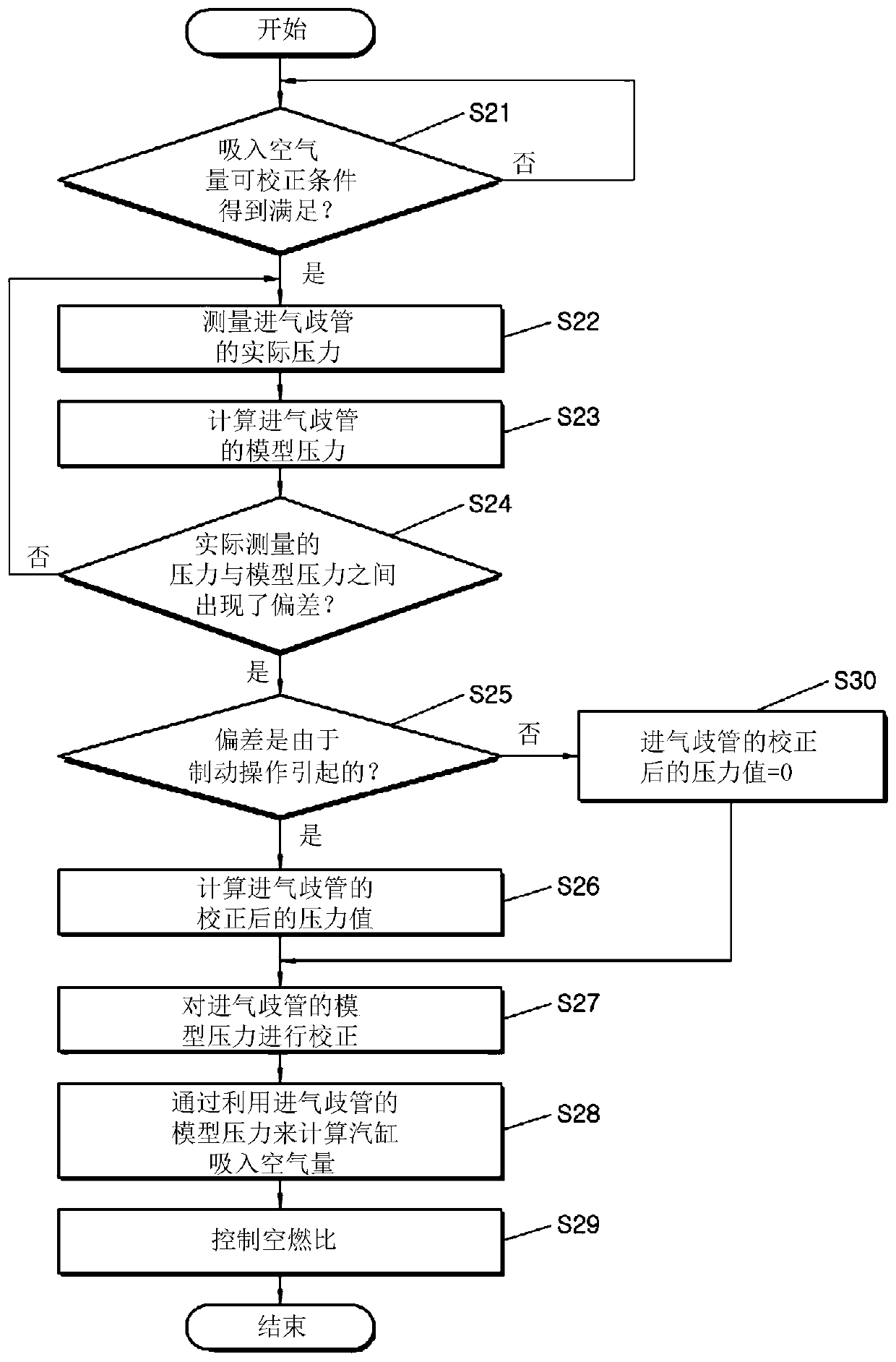

[0039] figure 2 is a flowchart showing an air-fuel ratio control method according to an embodiment of the present invention.

[0040] Such as figure 2 As shown, when the air-fuel ratio control method is executed, it is firstly determined in step S10 whether the intake air amount correctable condition has been satisfied. The intake air amount correctable condition is a condition for determining whether or not it is an operating state of the engine suitable for applying the air amount flowing into the intake manifold 13 from the brake booster 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com