An internal self-cleaning centrifugal fan

A centrifugal fan, self-cleaning technology, used in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problem of difficult to clean pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

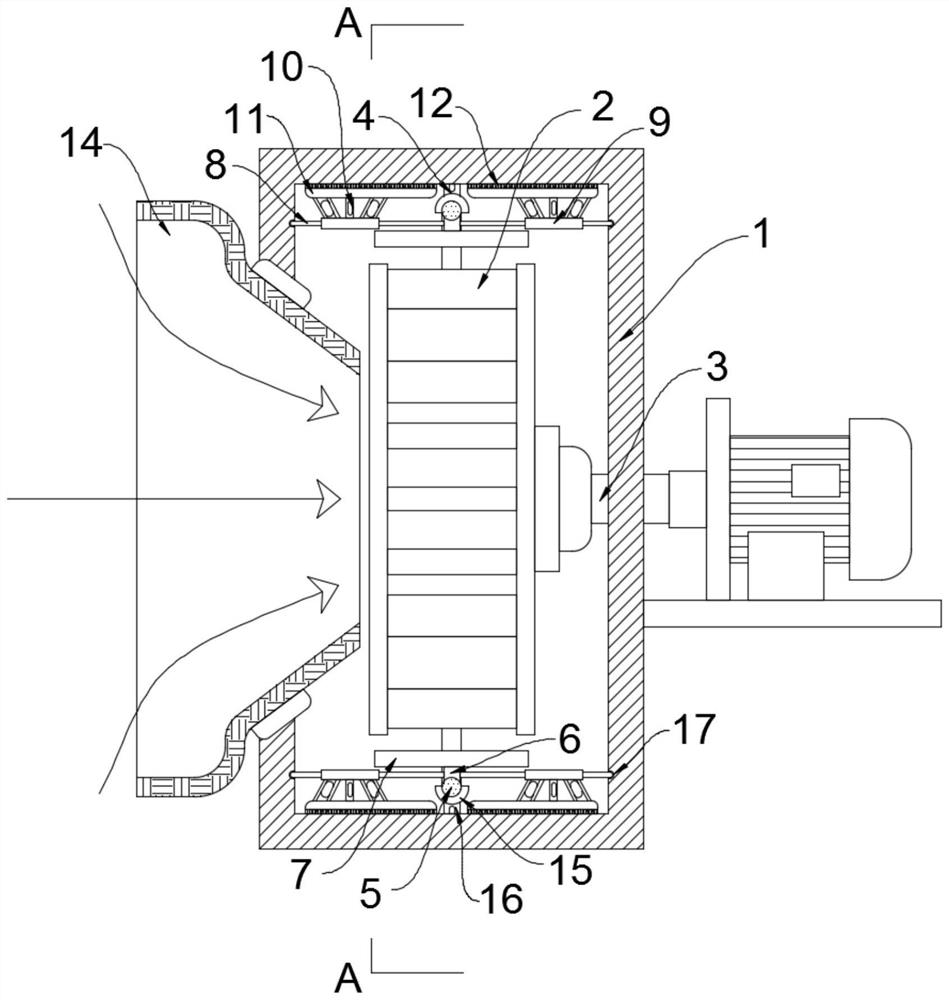

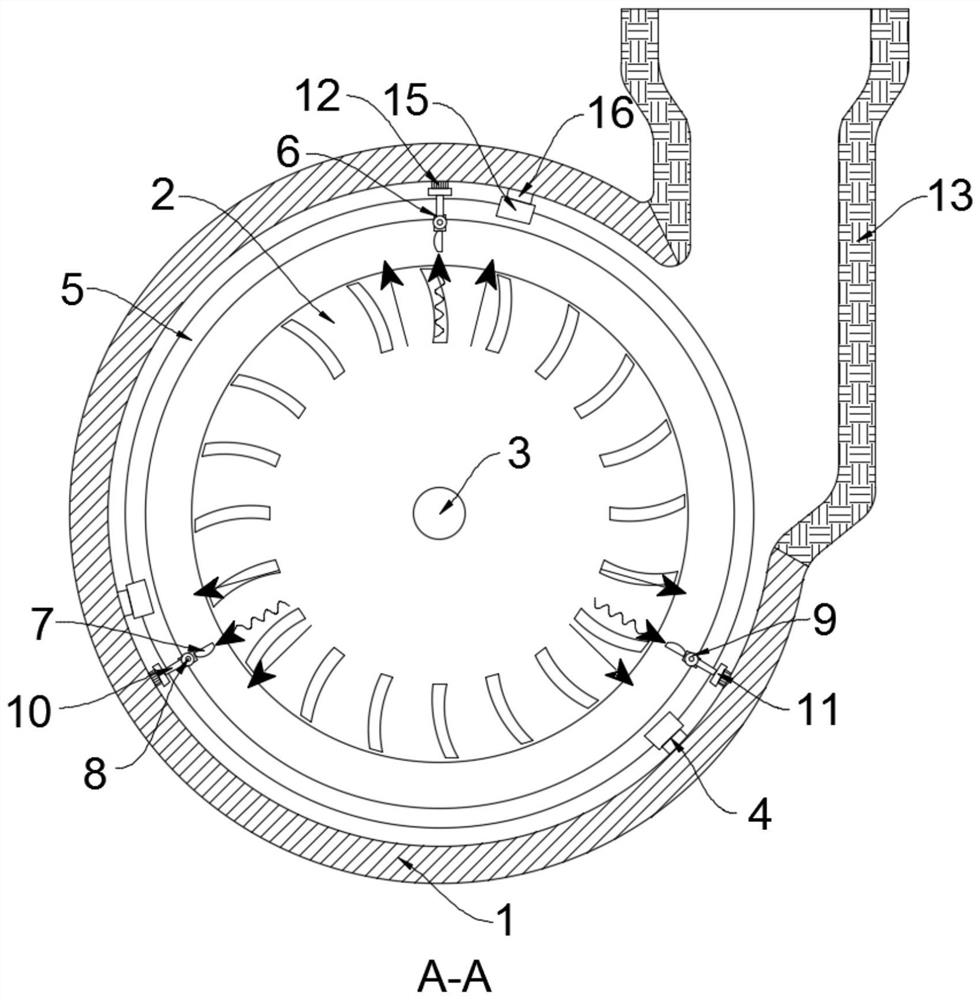

[0021] Such as Figure 1-2 As shown, an internal self-cleaning centrifugal fan includes a housing 1, the housing 1 is provided with an impeller 2, the outer wall of the housing 1 is provided with a driving mechanism, and the driving mechanism drives the impeller 2 to rotate through the rotating shaft 3, and the inner side of the housing 1 The position of the wall corresponding to the impeller 2 is fixedly connected with a plurality of support members 4, and the same slide ring 5 is slidably connected to the plurality of support members 4. Specifically, the support member 4 includes an arc-shaped support ring 15, and the support ring 15 and the slide ring 5 is slidingly connected, the lower end of the support ring 15 is fixedly connected to the inner side wall of the housing 1 through the support block 16, and the support ring 15 is slidably connected to the sliding ring 5 through a plurality of balls.

[0022] In this embodiment, the upper end of the sliding ring 5 is fixedly ...

Embodiment 2

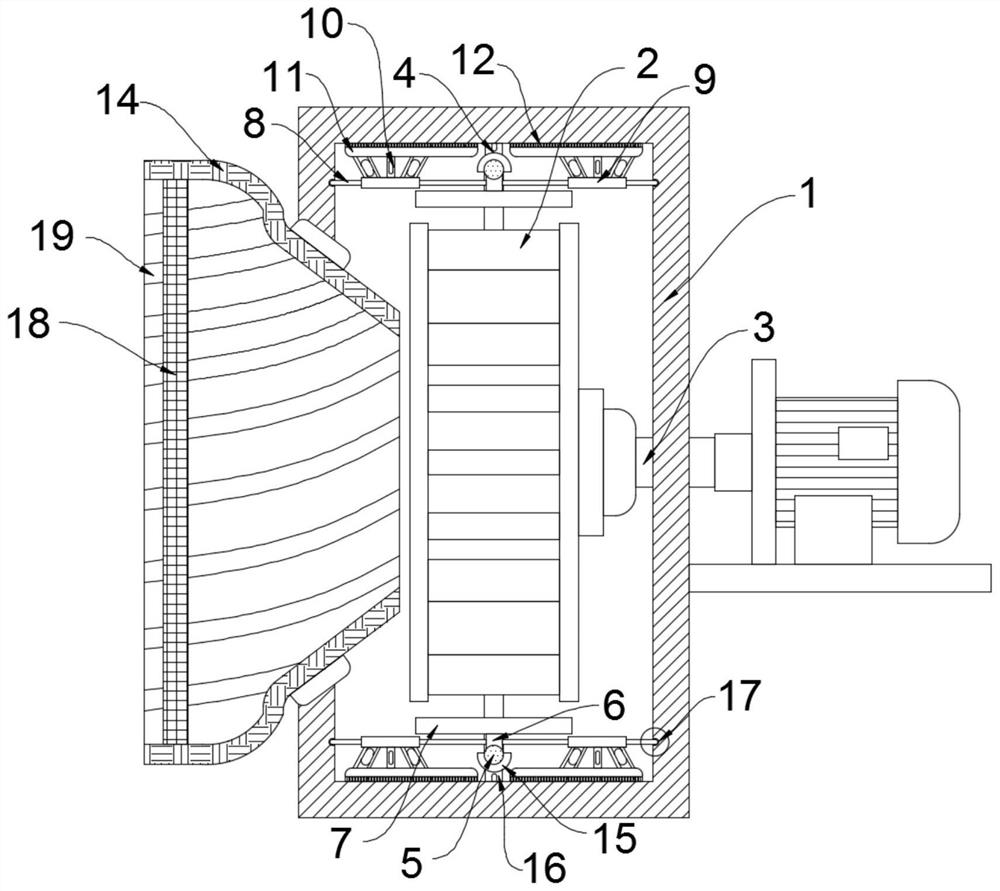

[0028] Such as Figure 3-4 As shown, the difference between this embodiment and Embodiment 1 is: the setting of the threaded bar 19, when the ventilator is working, a large amount of outside air is sucked from the air inlet tube 14, wherein a part of the air comes from the left and right sides of the air inlet tube 14 side rather than the direction facing the air inlet tube 14, this part of the air will be inclined in a certain direction after being sucked into the air inlet tube 14, and will continue to flow in the air inlet tube 14 until it hits the side wall of the air inlet tube 14 Finally, a part of the air is brought in by the horizontal wind of the mainstream, while the other part is reflected after the impact and continues to move in the air inlet tube 14 with an oblique attitude, which leads to the existence of multiple directions in the air inlet tube 14. The airflows collide or push each other to form a turbulent flow area, which causes the air intake efficiency of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com