Food safety credible tracing method based on QR code

A food safety, two-dimensional code technology, applied in the field of food safety, can solve the problems of consumers being unclear, users and merchants shirking each other, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

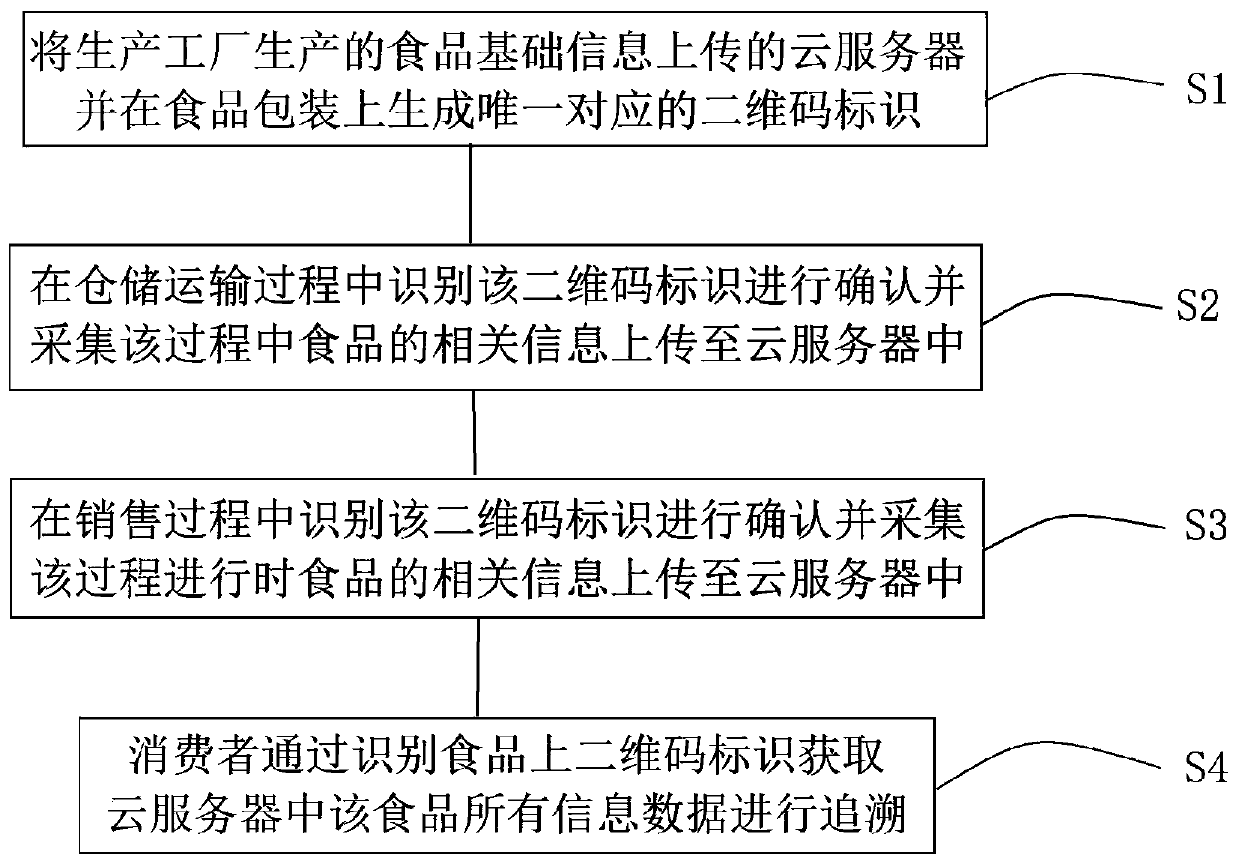

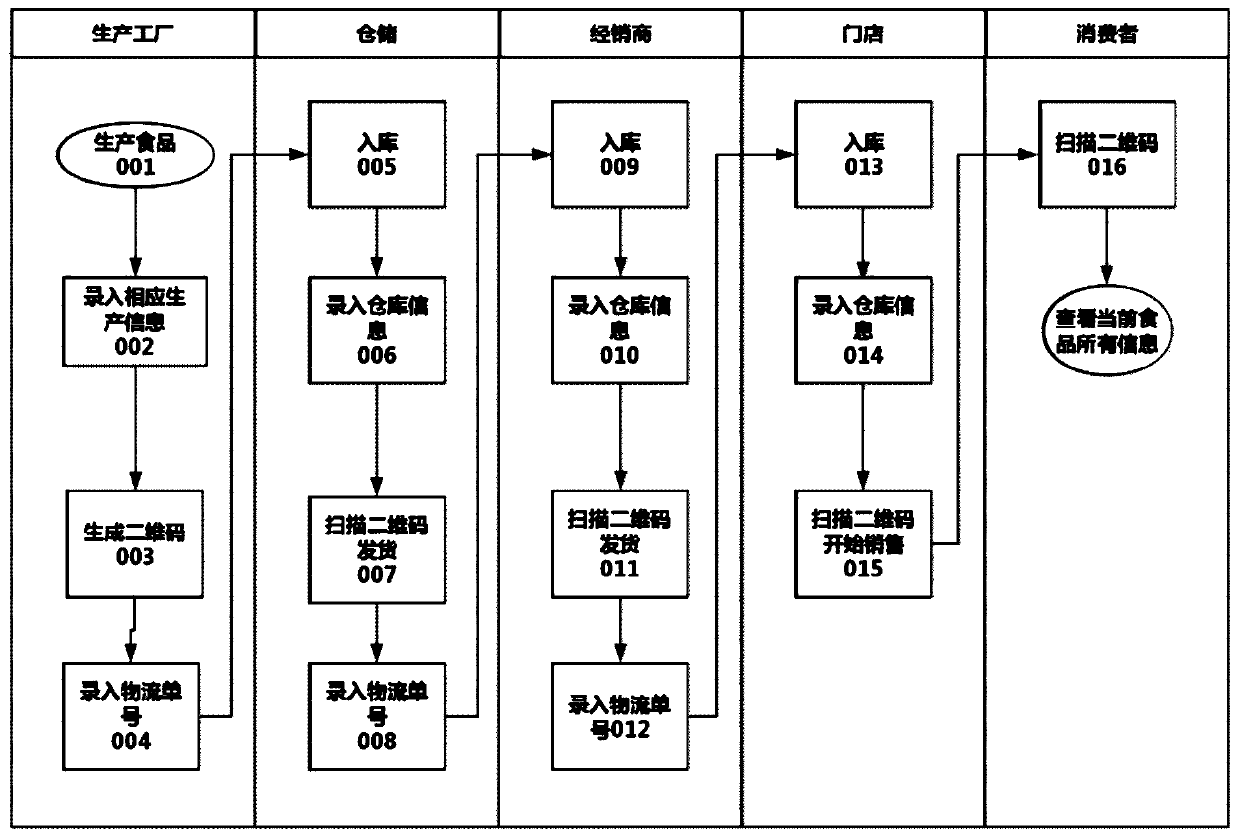

[0028] Such as figure 1 and figure 2 As shown, a method for food safety credible traceability based on two-dimensional code, the method for food safety credible traceability based on two-dimensional code comprises the following steps:

[0029] Step S1: upload the basic information of the food produced by the production factory to the cloud server and generate a unique corresponding two-dimensional code identification on the food packaging;

[0030] The basic unit of all production commodities will generate a unique QR code, which records all the production information of this product, such as production date, shelf life, raw material origin and other information. The factory uploads the batch of food reports to the server for re-inspection and review.

[0031] Step S2: Identify the QR code for confirmation during warehousing and transportation, collect relevant food information during the process and upload it to the cloud server;

[0032] In practical application, in the ...

Embodiment 2

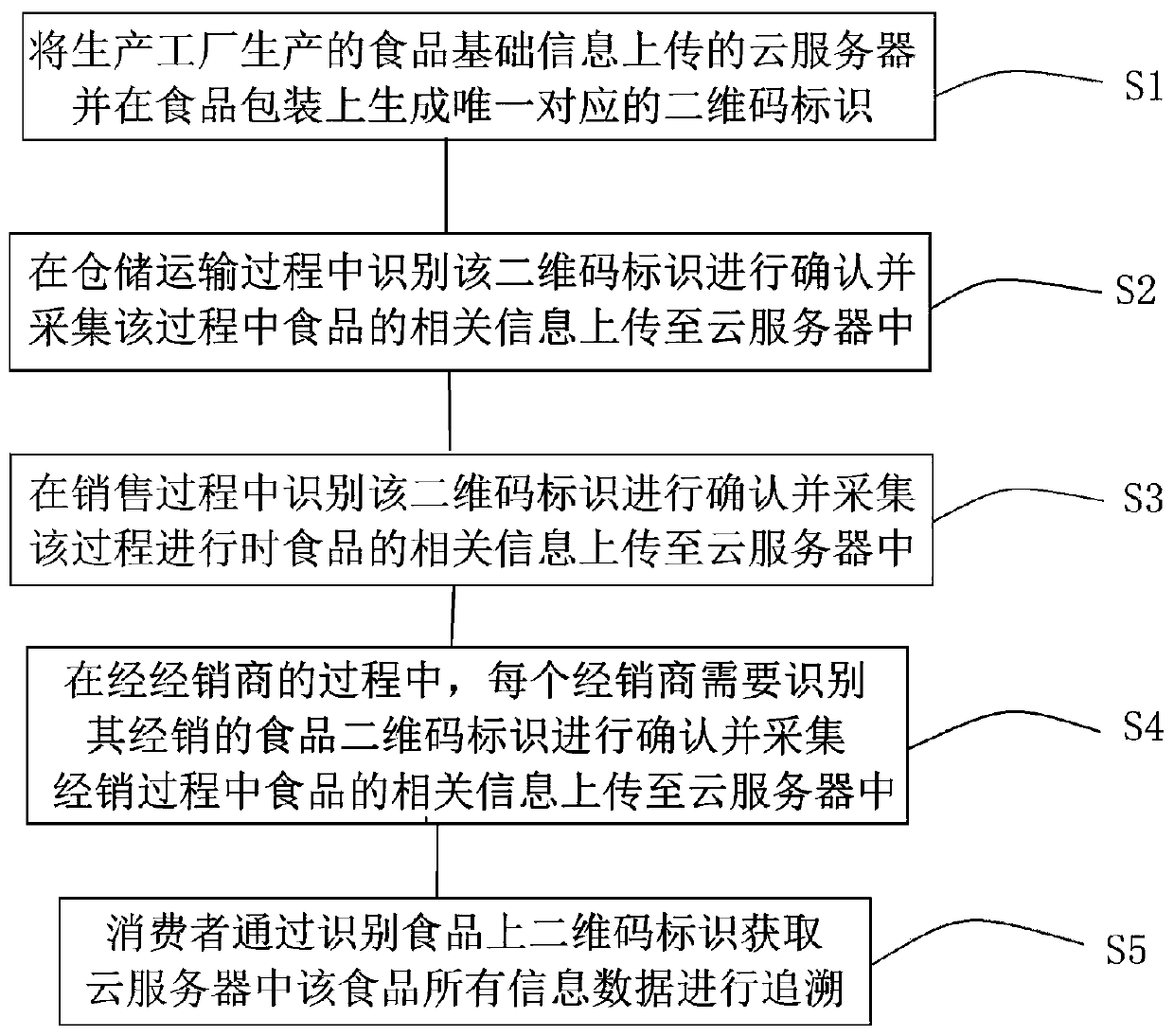

[0045] Such as figure 2 and image 3 As shown, a method for food safety credible traceability based on two-dimensional code, the method for food safety credible traceability based on two-dimensional code comprises the following steps:

[0046] Step S1: upload the basic information of the food produced by the production factory to the cloud server and generate a unique corresponding two-dimensional code identification on the food packaging;

[0047] The basic unit of all production commodities will generate a unique QR code, which records all the production information of this product, such as production date, shelf life, raw material origin and other information. The factory uploads the batch of food reports to the server for re-inspection and review.

[0048]Step S2: Identify the QR code for confirmation during warehousing and transportation, collect relevant food information during the process and upload it to the cloud server;

[0049] In practical application, in the p...

Embodiment 3

[0064] Such as Figure 4 and Figure 5 As shown, a method for food safety credible traceability based on two-dimensional code, the method for food safety credible traceability based on two-dimensional code comprises the following steps:

[0065] Step S1: upload the basic information of the food produced by the production factory to the cloud server and generate a unique corresponding two-dimensional code identification on the food packaging;

[0066] The basic unit of all production commodities will generate a unique QR code, which records all the production information of this product, such as production date, shelf life, raw material origin and other information. The factory uploads the batch of food reports to the server for re-inspection and review.

[0067] Step S2: Identify the QR code for confirmation during warehousing and transportation, collect relevant food information during the process and upload it to the cloud server;

[0068] In practical application, in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com