A hydraulic processing method for glass fiber reinforced plastic products

A technology of hydraulic processing and glass fiber reinforced plastics, applied in manufacturing tools, punching machines, presses, etc., can solve problems such as slow heavy load speed, single slide down speed, and pause.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

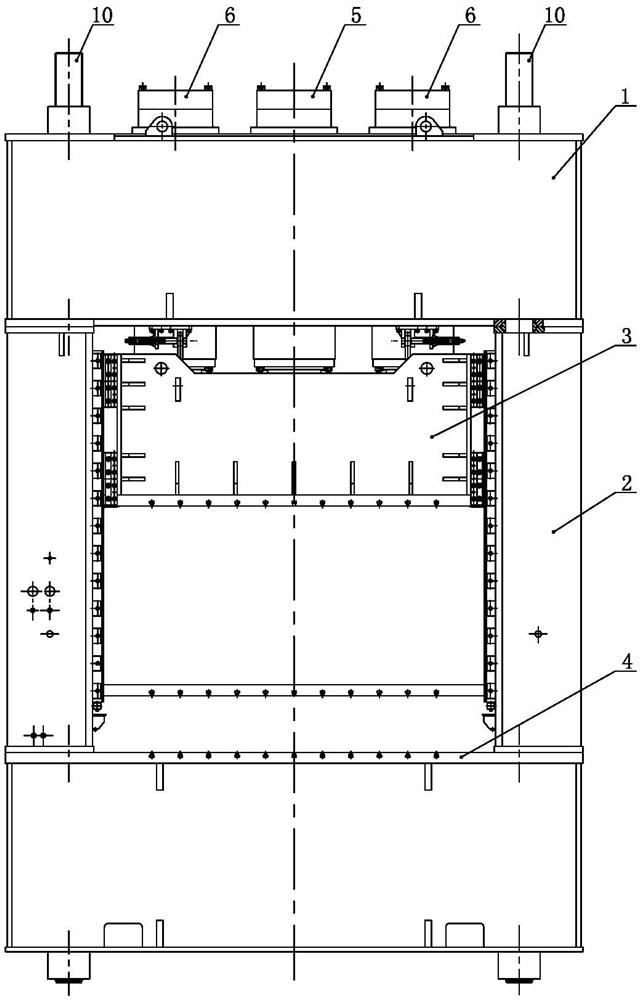

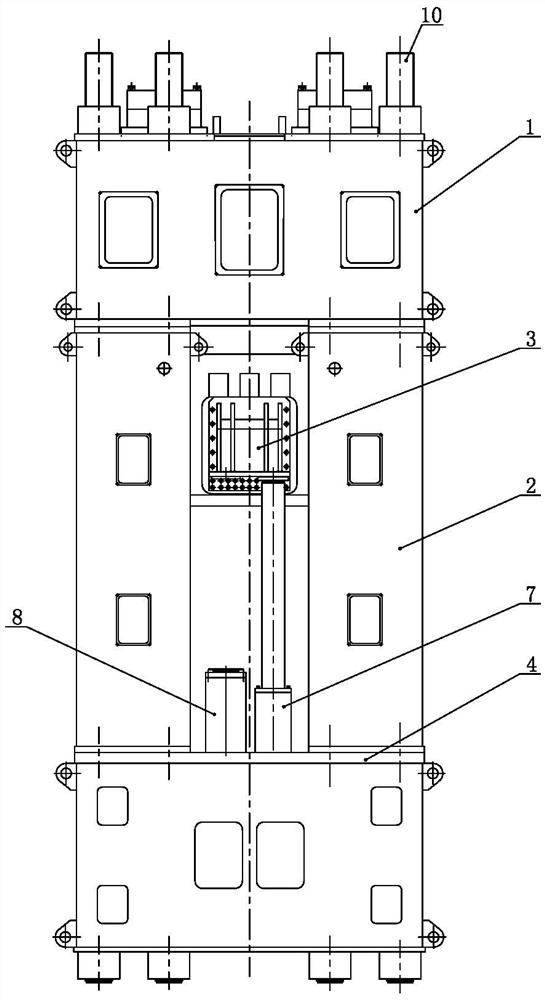

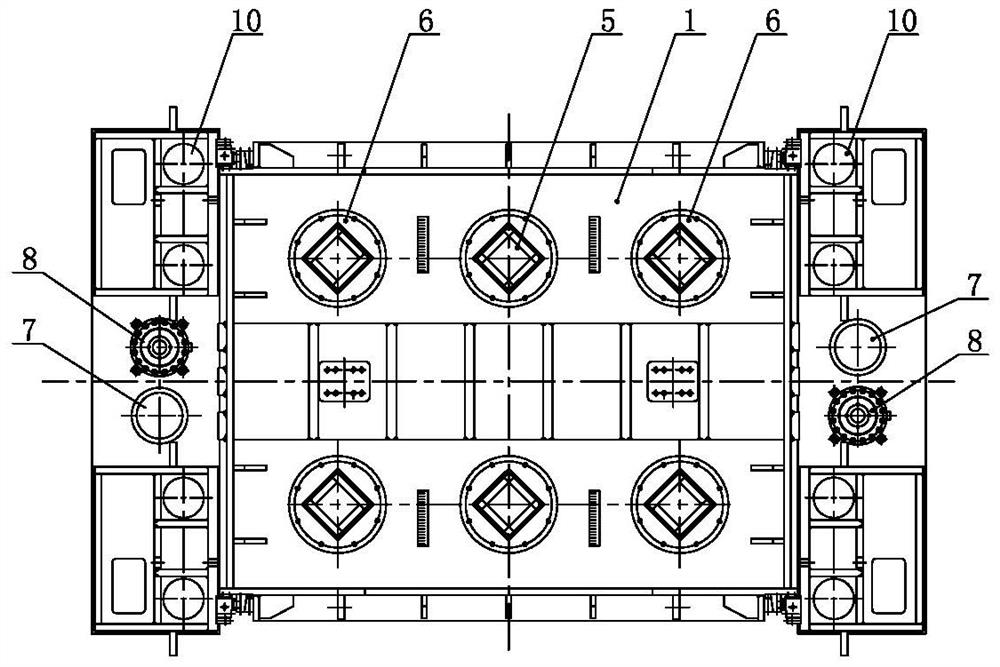

[0022] Such as Figure 1 to Figure 4 As shown, the hydraulic machine used in the present invention includes a workbench 4, four corners of the workbench 4 are equipped with columns 2, and the tops of the front and back rows of columns are connected to each other by the upper beam 1 extending in the left-right direction respectively, and each column's The front part and the rear part are respectively plugged with pull rods 10, and the upper ends of each pull rod 10 pass through the top of the upper beam 1 and are fixed on the upper beam 1 by upper nuts, and the lower ends of each pull rod 10 pass through the bottom of the workbench 4 respectively. and fixed on the workbench by the lower nut; the middle part of the upper crossbeam 1 is respectively equipped with middle cylinders 5, and the left and right sides of the middle cylinder 5 are respectively symmetrically installed with side cylinders 6, and the lower ends of the plungers of each middle cylinder 5 and side cylinder 6 B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com