Anti-scratch structure of roller table for industrial heating furnace

A heating furnace and anti-scratch technology, applied in the field of roller table accessories, can solve the problems of roller table scratches, anti-scratch structure damage, affecting service life, etc., to avoid damage, facilitate loading and unloading, and widely The effect of the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

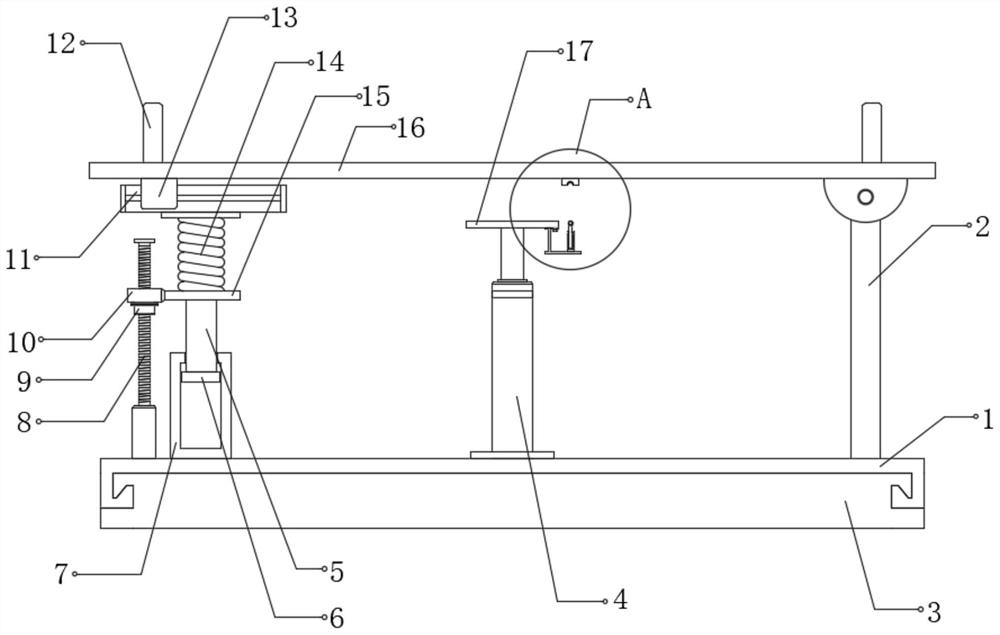

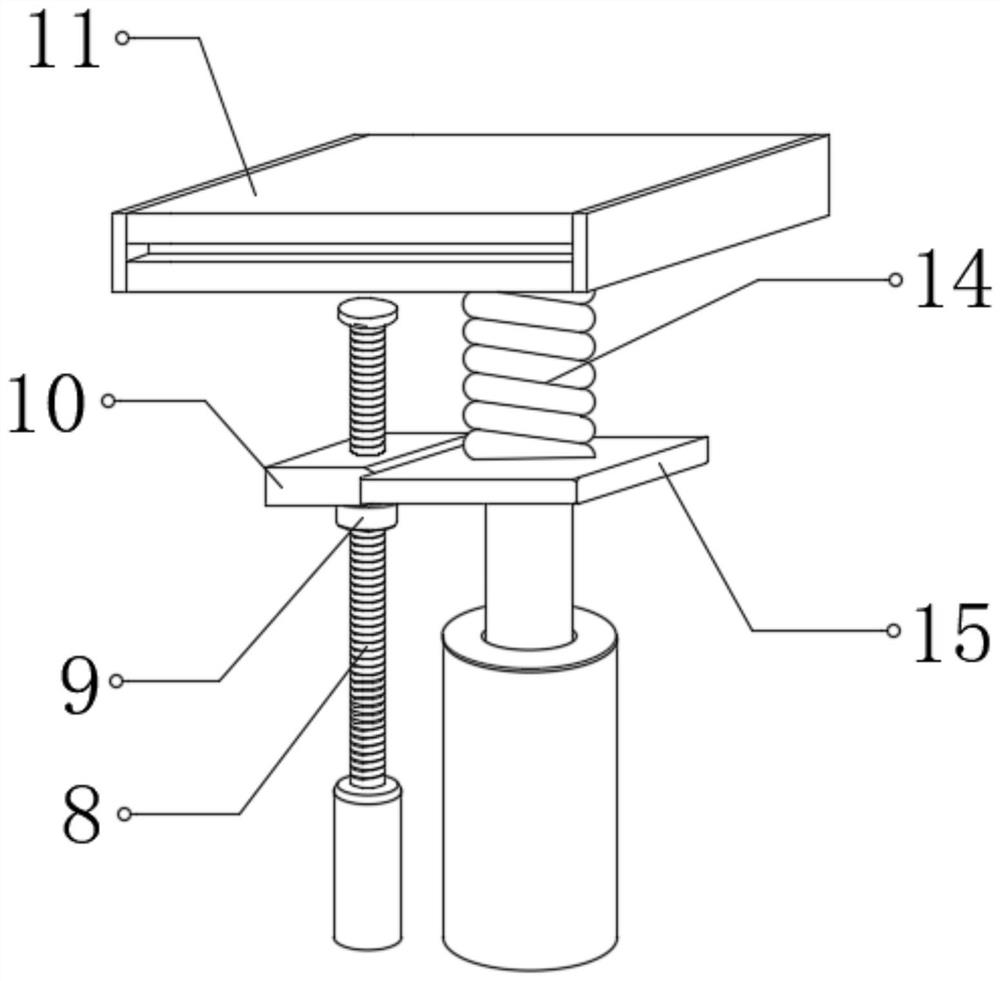

[0028] refer to Figure 1-3 , a roller table anti-scratch structure for industrial heating furnaces, including a base 1, a support plate 2, a tray 16 and a baffle 12, the support plate 2 is fixedly connected to one side of the top of the base 1, and the tray 16 is hinged to the support plate 2 Two baffles 12 are respectively welded on the two sides of the top of the tray 16, the top of the base 1 away from the support plate 2 is fixedly connected with the insertion socket 7, and the top of the insertion socket 7 is inserted with the insertion rod 5, the insertion rod 5 is fixedly connected to the top of the pressure plate 15, and the top of the pressure plate 15 is fixedly connected to the spring 14, the spring 14 is in a tightened state, the top of the spring 14 is fixedly connected to the slide rail 11, and the bottom of the tray 16 near the side of the slide rail 11 is fixed A slider 13 is connected, and the slider 13 is slidably connected to the top of the slide rail 11, a...

Embodiment 2

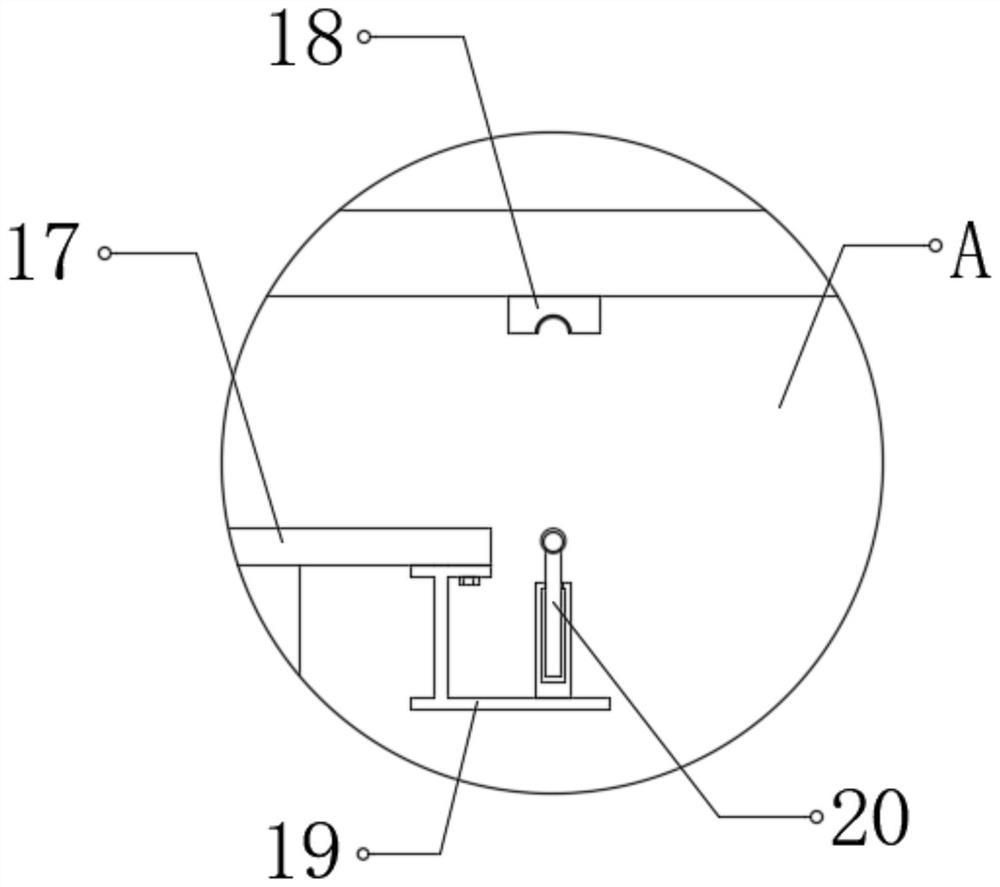

[0037] refer to Figure 4 , a roller table anti-scratch structure for industrial heating furnaces. Compared with Embodiment 1, this embodiment has two horizontal grooves on the top of the tray 16, and two baffles 12 are respectively clamped inside the two horizontal grooves. The sides of the two baffles 12 that are close to each other are welded with first sleeves 21, the insides of the two first sleeves 21 are inserted with pins 22, and the bottoms of the two pins 22 are inserted with second sleeves 23 , the two second sockets 23 are welded to the top of the tray 16 .

[0038]Working principle: the baffle 12 is fixed on the top of the pallet 16 by the pin 22, and the pin 22 is pulled out of the first socket 21 and the second socket 23, and the baffle 12 can be disassembled, which is convenient for loading and unloading of workpieces .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com