Sheet-pile wall structure and roadbed structure

A technology for pile-slab walls and subgrades, applied to sheet pile walls, foundation structure engineering, roads, etc., can solve problems such as not being able to meet the vertical protection height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

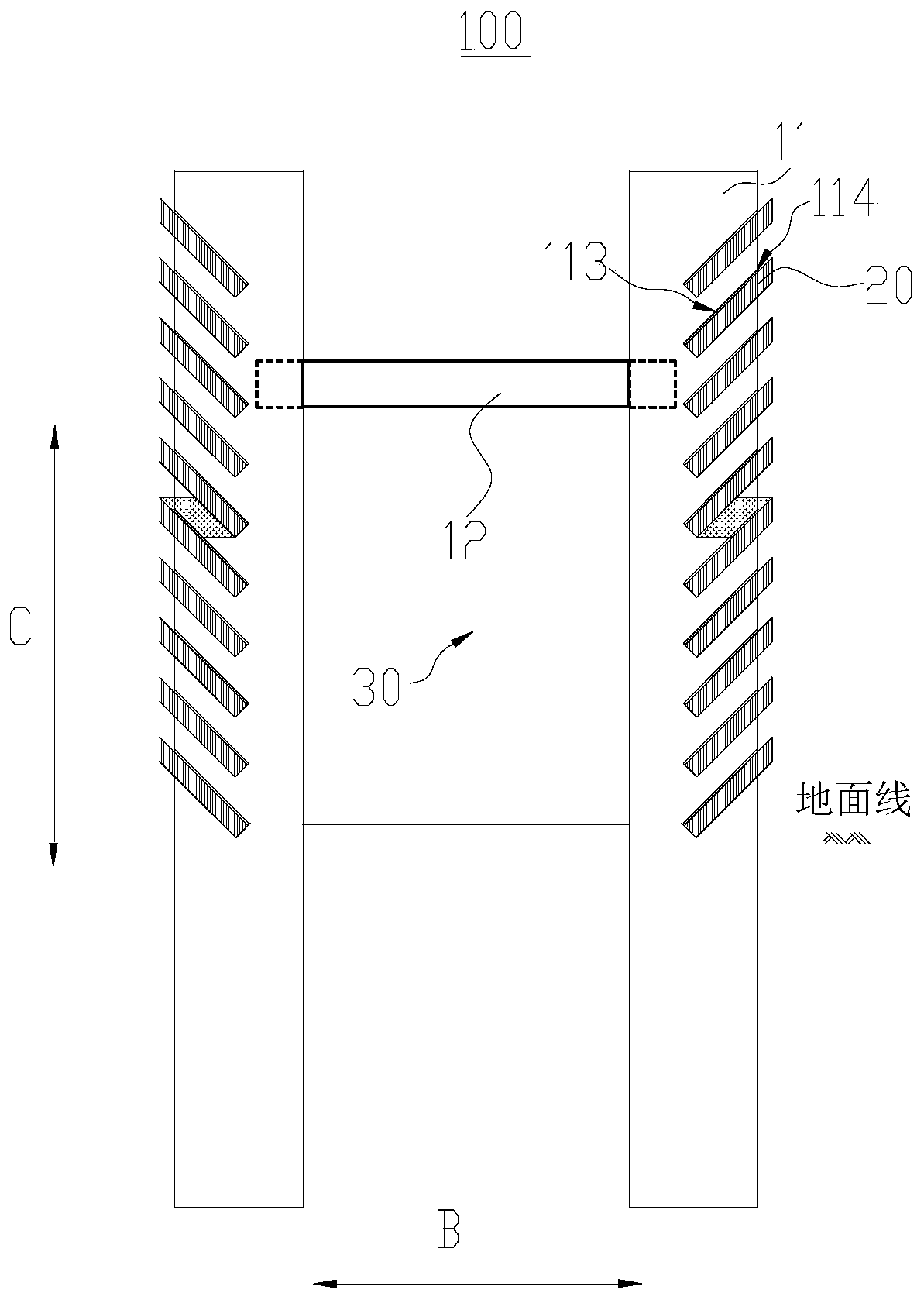

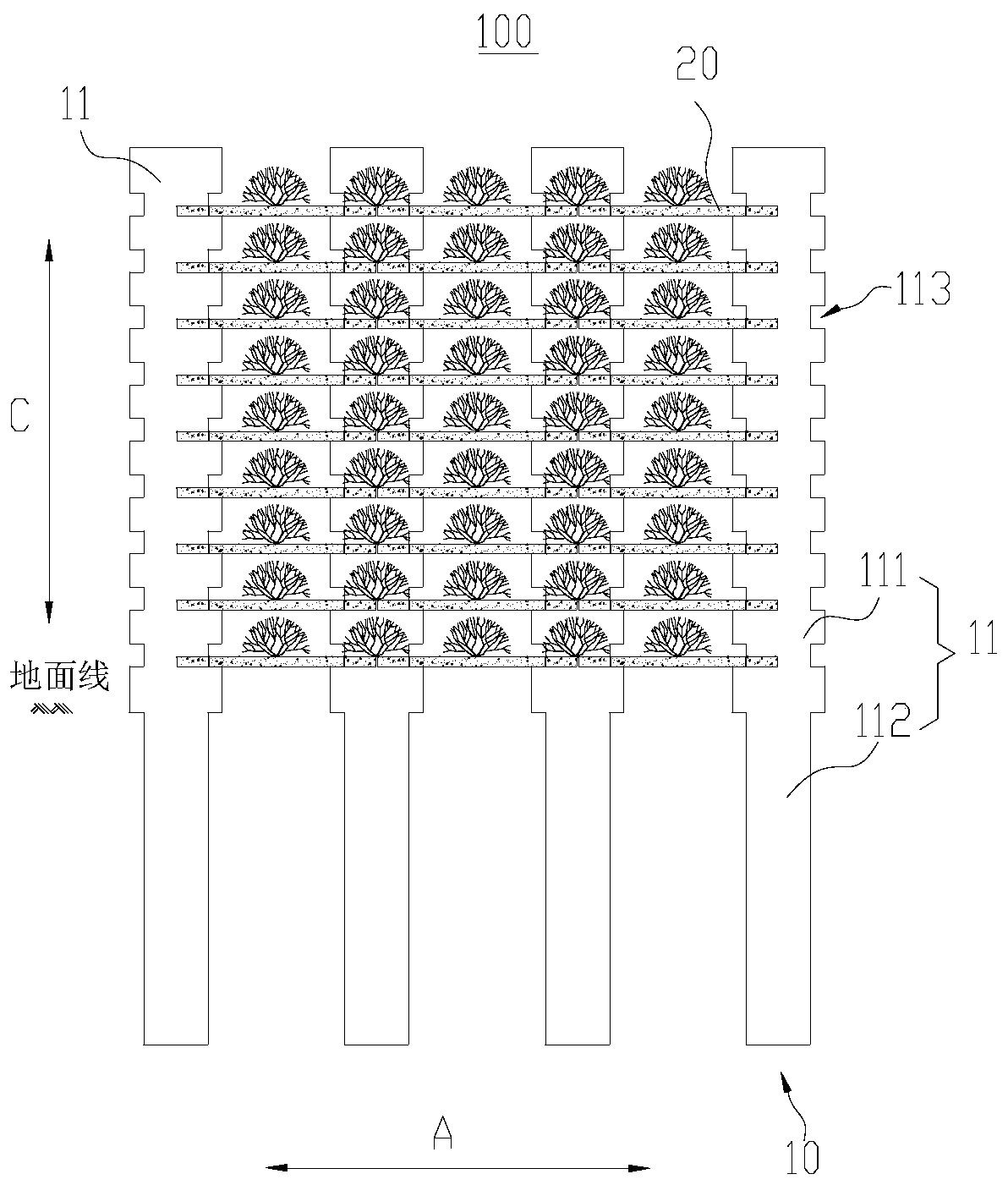

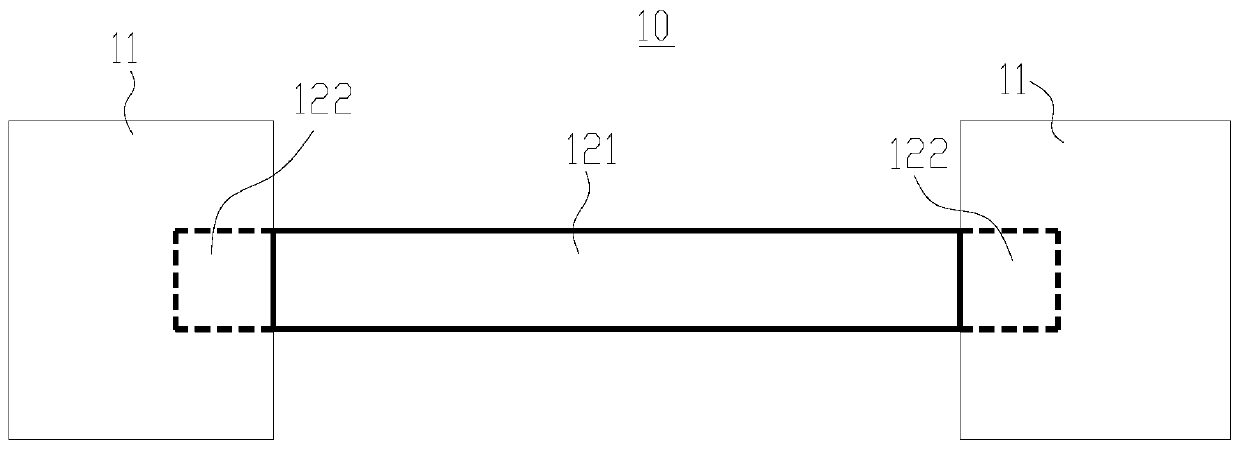

[0042] like figure 1 , figure 2 As shown, the embodiment of the first aspect of the present application provides a pile-slab wall structure 100. The pile-slab wall structure 100 includes a plurality of anti-sliding pile structural units 10 and soil retaining panels 20 arranged at intervals along the front-back direction A. Each anti-slide pile structural unit 10 includes a beam 12 and two anti-slide piles 11 arranged at intervals along the left-right direction B, and the two anti-slide piles 11 are connected by the beam 12 . Every two adjacent anti-slide piles 11 in the front-rear direction A are connected by at least one soil retaining plate 20 . All the anti-slide piles 11 and the earth retaining board 20 jointly define the filling space 30 filled with the reinforced soil subgrade 200 . The two anti-slide piles 11 facing each other in the left-right direction B are connected by a beam 12 , which can ensure the relative stability of the two anti-slide piles 11 . In some spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com