Full-section precast concrete pouring method

A prefabricated concrete and full-section technology, applied in construction, manufacturing tools, artificial islands, etc., can solve problems such as difficult maintenance of cracks, high pouring maintenance costs, immature pouring technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with test examples and specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

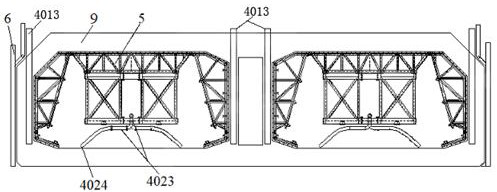

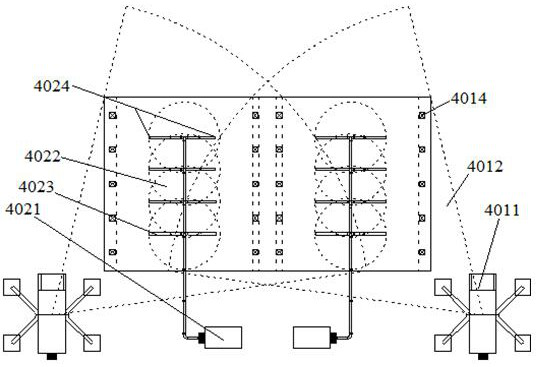

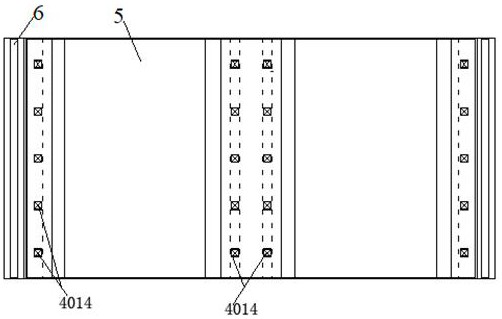

[0041] Specific examples are as follows, such as figure 1 as shown, figure 1 is the front view of the full-section precast concrete pouring of the immersed tube segment segment 7, figure 1 The pouring of the immersed tube segment 7 is shown. The formwork system applied to the outer formwork 6, the outer formwork 6 and the end form forms an immersed tube segment with the same shape as the immersed tube segment 7 after the setting is completed. section space;

[0042] Among them, the immersed tube segment 7 can be formed into a single immersed tube segment alone, or a single immerse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com