A Hydraulic Actuator with Cushioning at the Beginning of Stroke

A hydraulic actuator and stroke technology, applied in the direction of fluid pressure actuating devices, etc., can solve the problems of complex structure of the hydraulic system, large installation space, increased cost of use and maintenance of the hydraulic system, etc., to achieve convenient installation and maintenance, low cost of use Low, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0032] The invention relates to an actuator for reciprocating linear motion in a hydraulic system, in particular to a hydraulic actuator capable of realizing a buffer function at the initial end of a working stroke, that is, a hydraulic actuator for buffering at the initial end of a stroke.

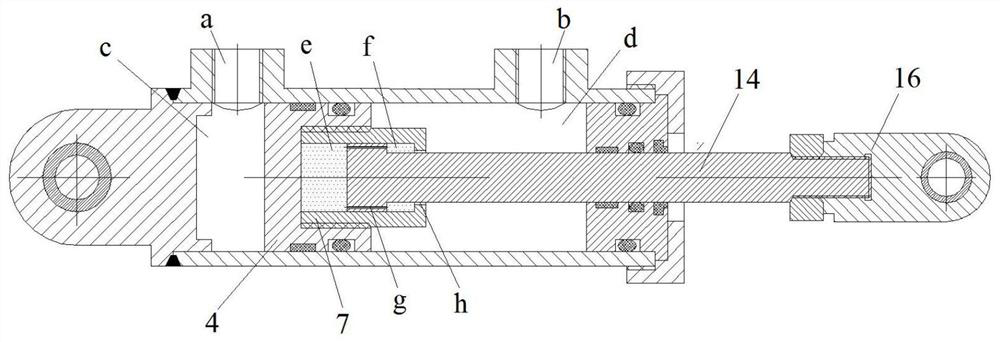

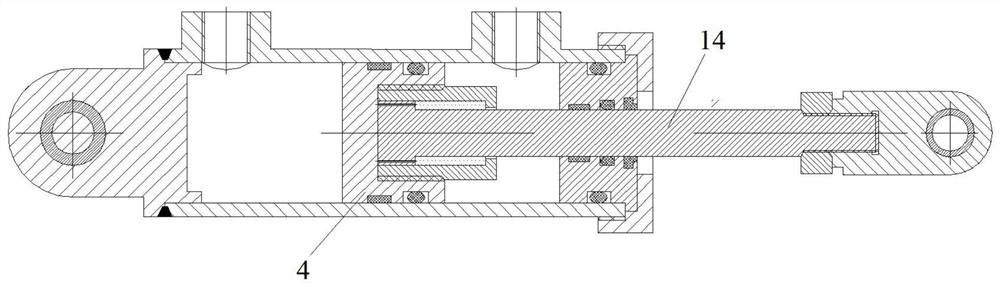

[0033] Such as Figure 1 to Figure 6 As shown, the hydraulic cylinder mainly includes a cylinder body 1, a cylinder bottom 2, a piston 4, a buffer piston 7, a guide sleeve 9, a static seal 10, a locking sleeve 11, a dust-proof ring 13, a piston rod 14, and a lock nut 15. Rod head 16 and bearings of different specifications, support rings and dynamic seals, etc., wherein the two ends of the cylinder 1 are respectively provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com