Tuned liquid mass damper

A technology of liquid mass and damper, which is applied in the direction of building components, shockproof, building types, etc., can solve the problems of not having tuned liquid mass damper, bulky fire water tank, leakage of liquid damper, etc., and achieve excellent vibration reduction effect , Simple structure, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

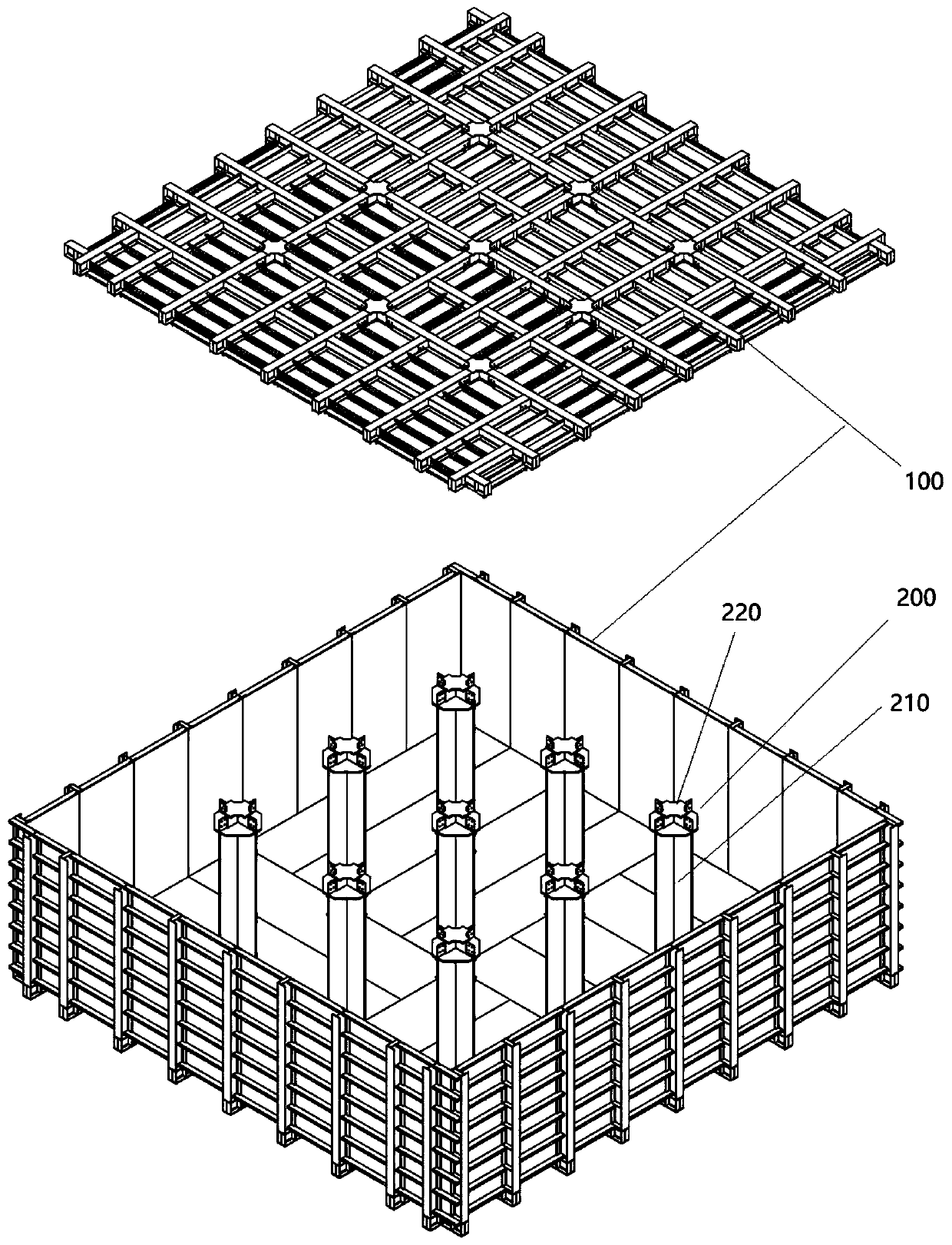

[0035] Such as figure 1 As shown, the present invention provides a tuned liquid mass damper, including: a liquid storage tank 100 and a liquid storage tank 100 arranged in the water storage tank 100 for adjusting the flow resistance of the liquid contained in the liquid storage tank 100 The liquid damping adjusting device 200 required for time;

[0036] The lower end surface and / or side wall of the liquid storage box body is provided with connecting pieces (not shown in the figure) required for the fast connection with the load-bearing wall and / or load-bearing beam of the building; The device 200 includes: a vertical column 210 with a cross-sectional shape perpendicular to the assembly axis direction, and a fastening kit 220 respectively arranged at both ends of the vertical column 210 for fixing the vertical column in the liquid storage tank The liquid damping adjusting device 200 is arranged in a plurality of numbers in the liquid storage tank 100, which are distributed in a ma...

Embodiment 2

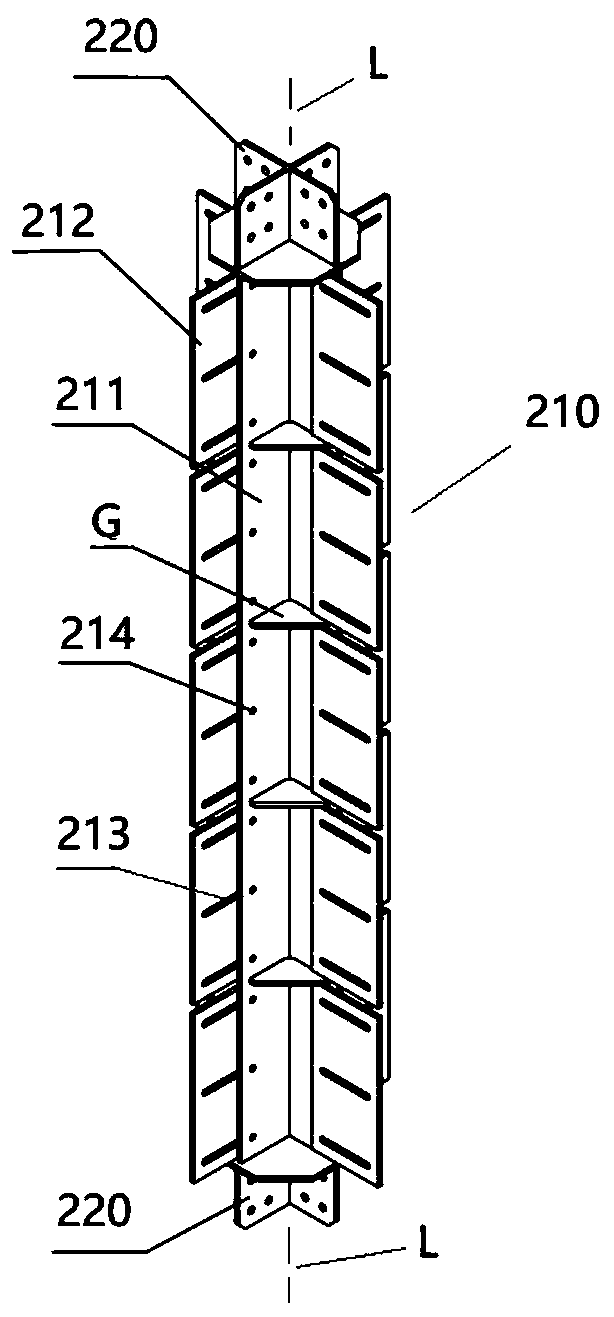

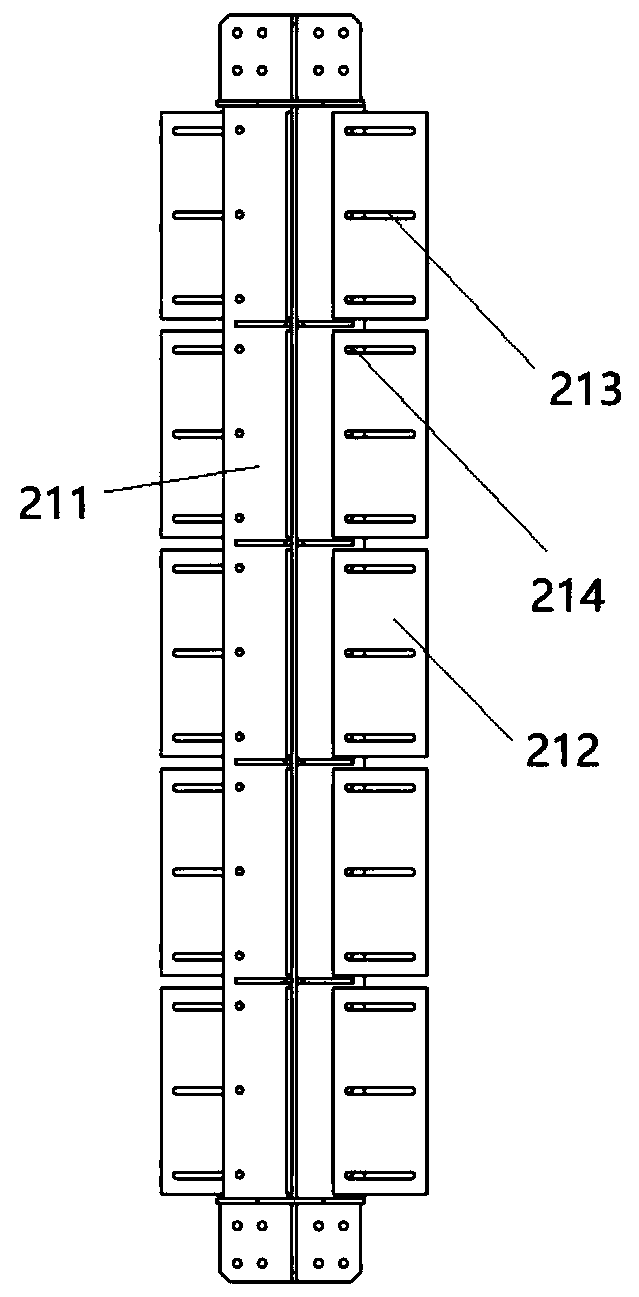

[0041] Such as Figure 2 to Figure 4 As shown, this embodiment is based on embodiment 1, the column 210 includes two vertically connected metal plates 211 and a plurality of wing plates 212; the metal plate 211 or the wing plate is provided with a transverse groove 213 The metal plate 211 and the wing plate 212 form a fixed connection with an adjustable relative position through the transverse groove 213 and the locking screw 214; the adjustment direction is perpendicular to the assembly axis L. When the above-mentioned column structure is applied to a fire water tank, the effect of adjusting the damping ratio can be achieved by adjusting the fastening position between the wing plate 212 and the metal plate 211.

[0042] Preferably, in figure 2 In the structure shown, in order to ensure that the cross structure connection formed by the two vertically connected metal plates 211 is more stable, a reinforcing rib G having a triangular shape shown in the figure can also be welded at...

Embodiment 3

[0047] Such as Figure 5 As shown, this embodiment is based on the above-mentioned embodiment, the structure of the fastening kit 220 includes: a base 222 provided with a cross slot 221 and a cross plug terminal 223 respectively provided at both ends of the column; The cross-sectional shape of the cross plug terminal 223 perpendicular to the direction of the assembly axis L is adapted to the shape of the cross slot; the connecting end 224 provided below the base 222 is used to connect to the bottom or top of the liquid storage tank. The lower end surface of the cover is fixedly connected by screws.

[0048] Preferably, such as Image 6 As shown, the connecting end provided under the base is provided with an arc-shaped slot 225 for adjusting the rotation angle of the cross slot 221 relative to the assembly axis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com