An industrial computer control system with the function of running track measurement and control

A technology of running trajectory and control system, applied in general control system, control/regulation system, program control, etc., can solve the problems of low measurement and control accuracy and high false alarm rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

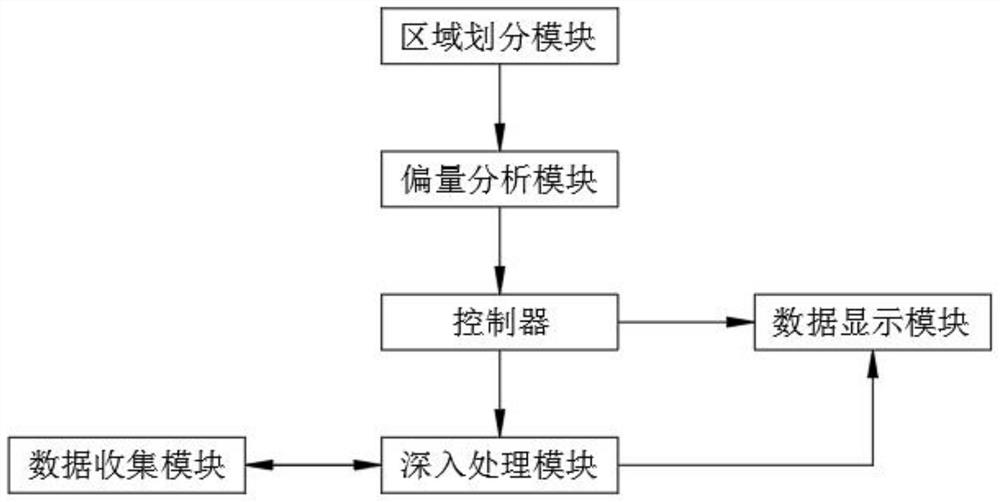

[0035] Such as Figure 1-2 As shown, an industrial computer control system with the function of running track measurement and control, including an area division module, an offset analysis module, a controller, an in-depth processing module, a data display module and a data collection module;

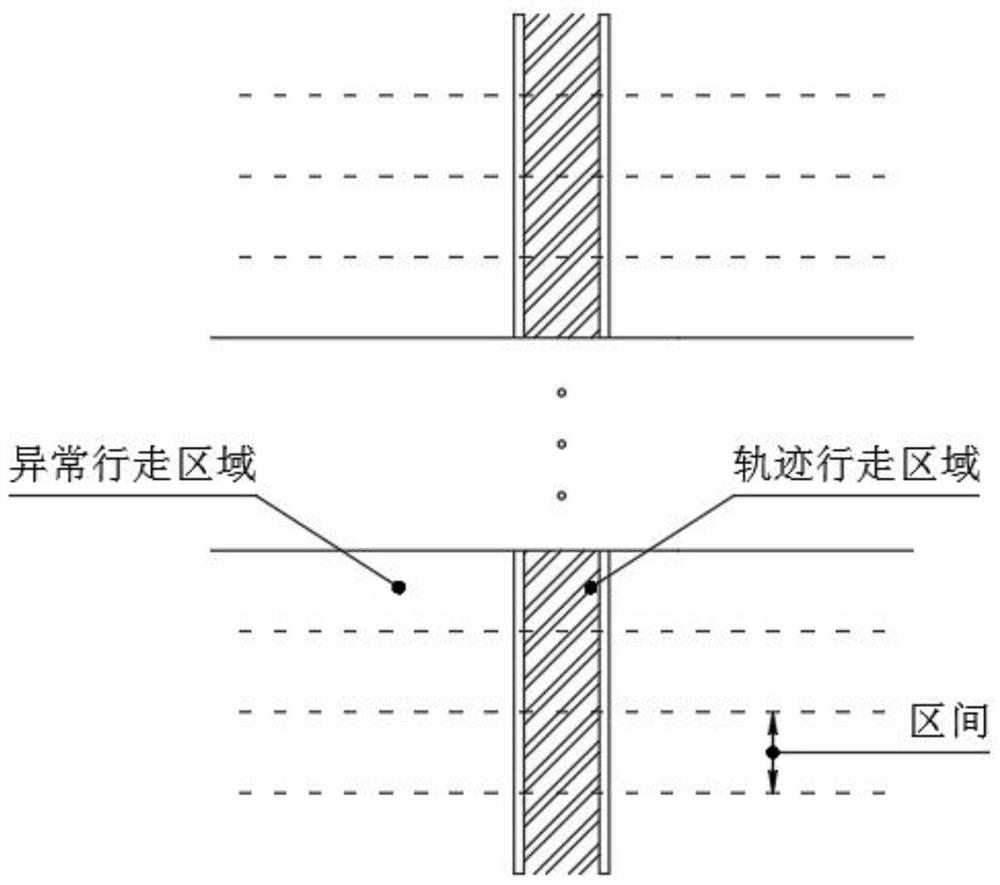

[0036] The area division module is used to divide the planar motion area of the logistics robot into trajectory walking area and abnormal walking area, and the trajectory walking area is derived according to the preset walking route of the logistics robot, and the abnormal walking area is through the periphery of the trajectory walking area Derived from the space, the trajectory walking area and the abnormal walking area are divided into each layer interval, and each layer interval in the two walking areas is in one-to-one correspondence with each other, and the industrial computer is embedded in the interior of the logistics robot;

[0037] The area division module also collects the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com