Conveyer and automatic marking press

A transmission device and creasing machine technology, applied in the direction of sending objects, transportation and packaging, thin material processing, etc., can solve the problems of belt deviation, affecting the transmission of paper by the transmission device, shaft and wheel misalignment, etc., to achieve good transmission effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

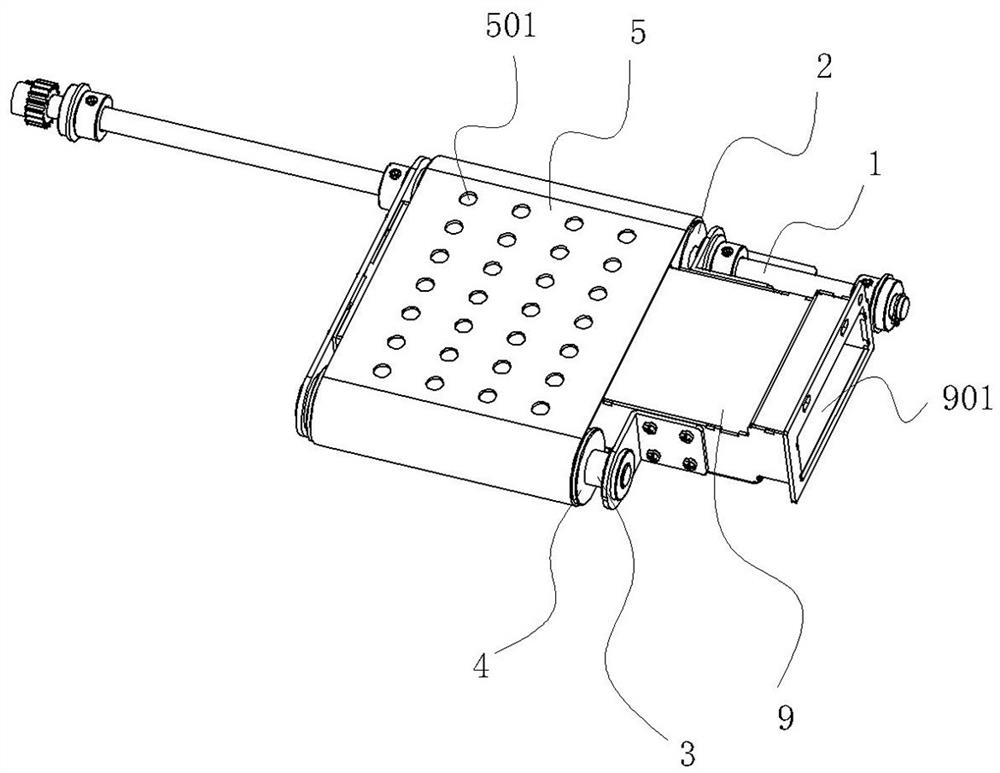

[0031] The invention discloses a conveying device comprising a driving shaft 1, a driving wheel 2, a driven shaft 3, a driven wheel 4 and a conveyor belt 5.

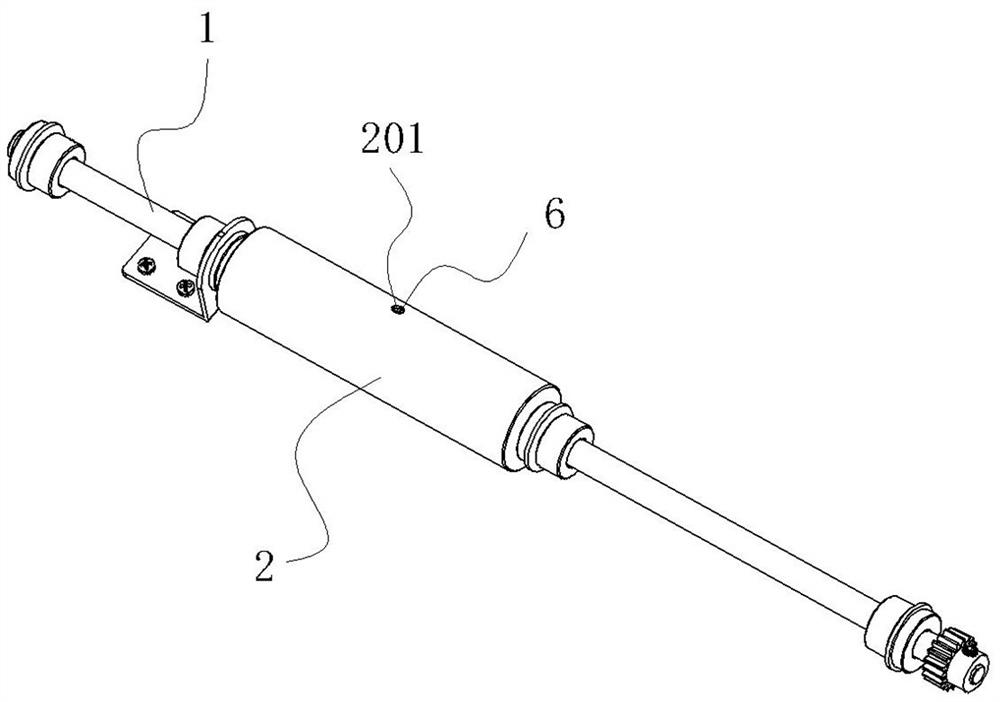

[0032] The driving shaft 1 is provided with a positioning hole 101 or a positioning groove. In this specific embodiment, the driving shaft 1 is provided with a positioning hole 101, and the positioning hole 101 is radially arranged. The driving wheel 2 is a hollow cylindrical structure. The driving wheel 2 is provided with a mounting hole 201 at a position corresponding to the positioning hole 101. The inner wall of the mounting hole 201 is provided with an inner wall. Thread. The driving wheel 2 is sleeved outside the driving shaft 1, and a gap is left between the driving wheel 2 and the driving shaft 1. The driving wheel 2 and the driving shaft 1 are connected by a connecting component, and the connecting component includes a connecting piece 6. The connecting member 6 has a cylindrical structure, one end of the connect...

Embodiment 2

[0036] Compared with the transmission device of the first embodiment, the transmission device disclosed in this embodiment has the following differences: the structure of the driving shaft and the driving wheel of the transmission device of this embodiment is different from that of the driven shaft and the driven wheel of the transmission device of the first embodiment. The structure is the same; the structure of the driven shaft and the driven wheel of the transmission device of this embodiment is the same as the structure of the driving shaft and the driving wheel of the transmission device of the first embodiment.

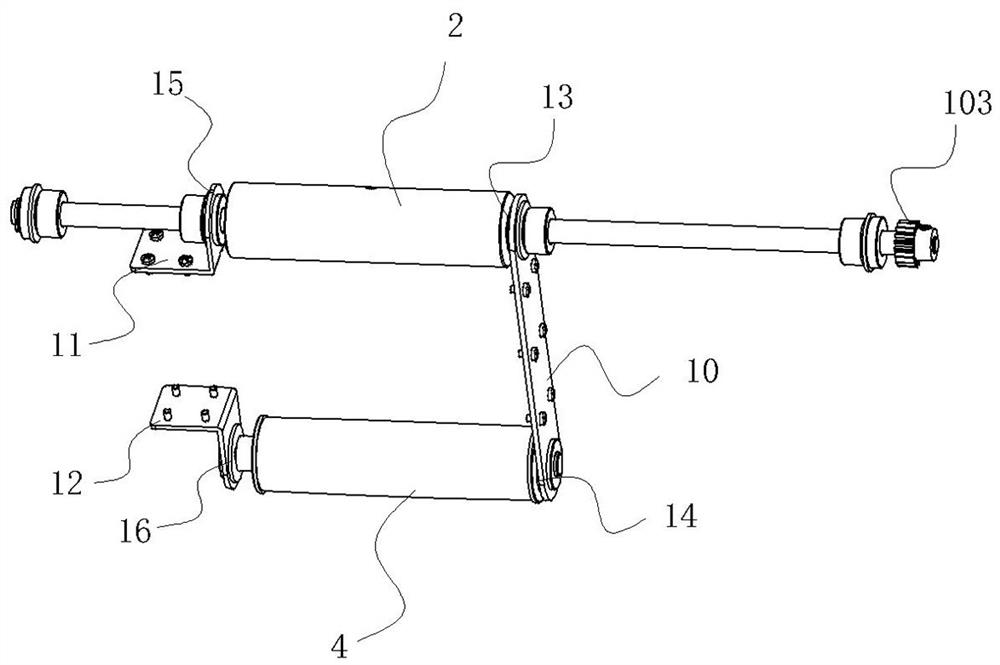

[0037] The conveyor belt is connected between the driving wheel and the driven wheel. The rotation of the driving shaft will drive the driving wheel to rotate. The driven shaft and the driven wheel are driven by the driving wheel and the conveyor belt to rotate. The driving wheel will float a little at the beginning under the action of centrifugal force, and it will...

Embodiment 3

[0039] Compared with the transmission device of the first embodiment, the transmission device disclosed in this embodiment has the following differences: the structure of the driven shaft and the driven wheel of the transmission device of this embodiment is different from that of the driving shaft and driving wheel of the transmission device of the first embodiment. The structure is the same. That is, the structure of the driving wheel and the driving shaft and the structure of the driven wheel and the driven shaft of the transmission device of this embodiment are all movably connected.

[0040] The conveyor belt is connected between the driving wheel and the driven wheel. The rotation of the driving shaft will drive the driving wheel to rotate. The driven shaft and the driven wheel are driven by the driving wheel and the conveyor belt to rotate. The driving wheel and the driven wheel will fluctuate a little at the beginning due to the centrifugal force. The shaft keeps coaxial ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap