Explosive-handling vehicle for community

A kind of community and car body technology, which is applied in blasting, motor vehicles, goods transport vehicles, etc., can solve the problems of gas tank overheating, indoor gas leakage and explosion, and cannot guarantee damage, so as to reduce the momentum capacity and avoid excessive damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

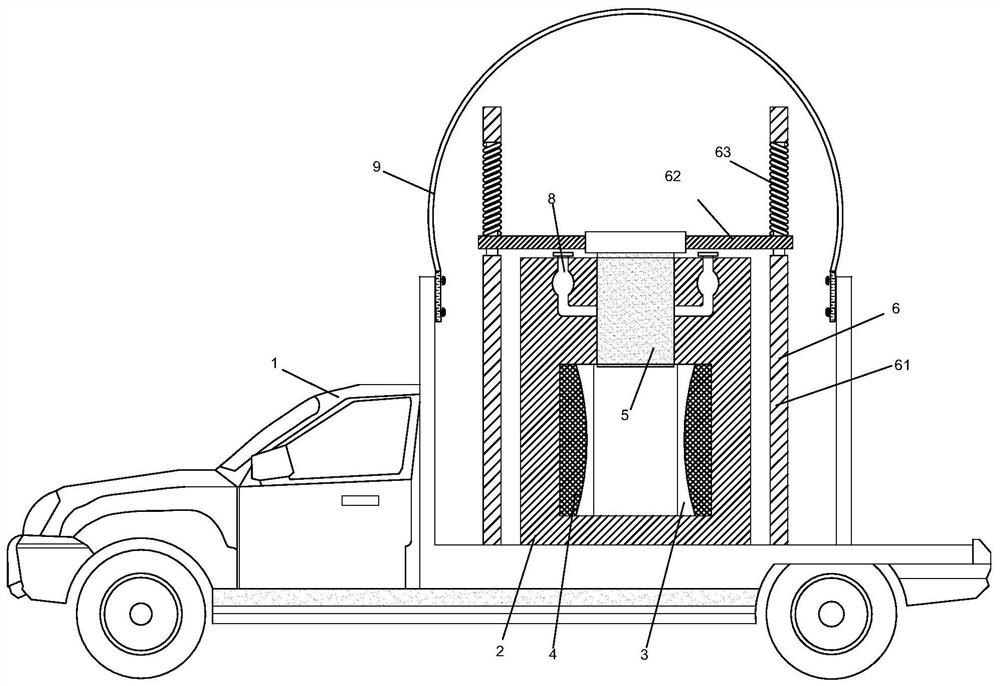

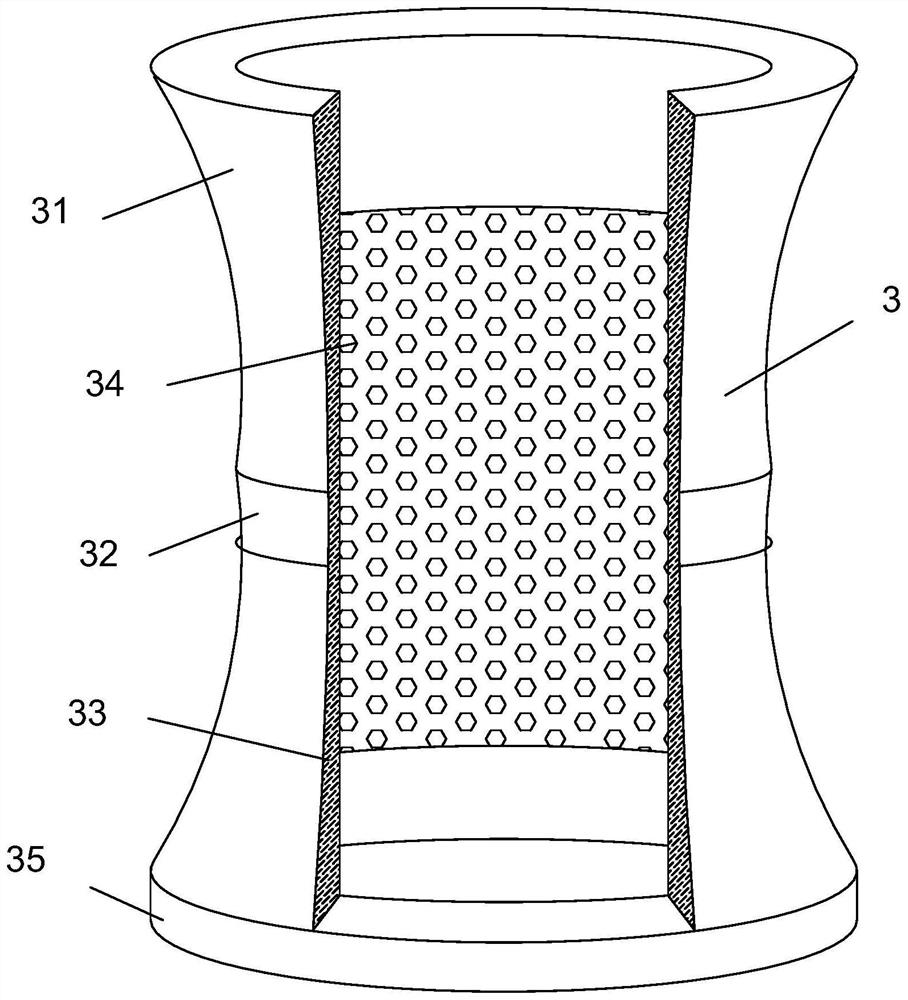

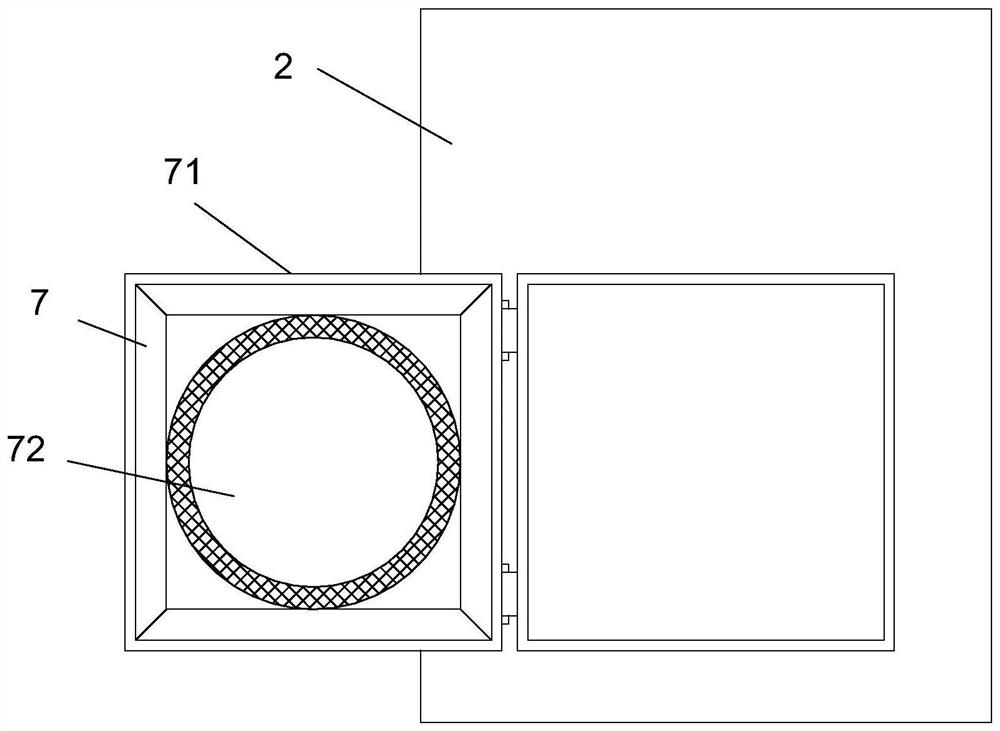

[0018] Please refer to figure 1 , figure 2 and image 3 , an explosion-proof vehicle for a residential area, comprising a vehicle body 1, an installation box 2, an explosion-discharge mechanism 3, a metal column 5 and a decompression mechanism 6, the installation box 2 is fixedly installed on the loading plate of the vehicle body 1, and the exhaust The explosion-proof mechanism 3 is installed in the installation box 2, and the explosion-proof mechanism 3 includes an explosion-proof tank 31, a memory metal ring 32, and a reinforcement tube 33. The explosion-proof tank 31 is fixedly installed in the installation box 2, and the explosion-proof tank 31 and the installation There is a material inlet at the corresponding place of the opening of the box 2. The middle part of the explosion-proof tank 31 is fixedly sleeved with a memory metal ring 32, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com