Structure and Construction Method of Negative Pressure Isolation Ward in Modular Prefabricated Hospital

A negative pressure isolation and construction method technology, which is applied in hospitals, heating methods, lighting devices, etc., can solve the problems of long construction period, many wet operations, and many welding operations, and achieve the effects of rapid construction, accelerated efficiency, and easy upgrades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

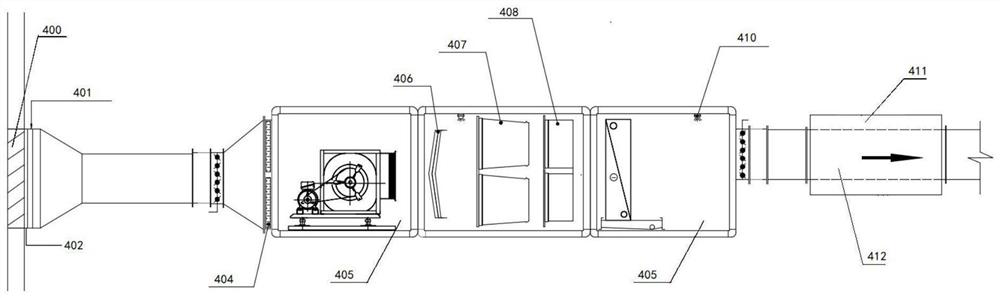

Embodiment 1

[0055] Such as Figure 12 As shown, this embodiment provides a modular assembly type hospital negative pressure isolation ward structure and construction method, including: measuring and setting out the line, popping up the position marking line of the object to be assembled; deepening the design and factory processing, and making the negative pressure isolation ward Divide into several functional modules and make a layout diagram; functional modules include HVAC modules, decoration modules, electrical modules, intelligent modules, medical gas modules and cabinet modules; the installation position of each functional module is adapted to the position marking line ; Install the HVAC module, decoration module, electrical module, intelligent module, medical gas module and cabinet module in sequence. After the above modules are installed, use medical silicone sealing strips or sealant to seal all the gaps in a dust-free environment To ensure the airtightness of the isolation ward. ...

Embodiment 2

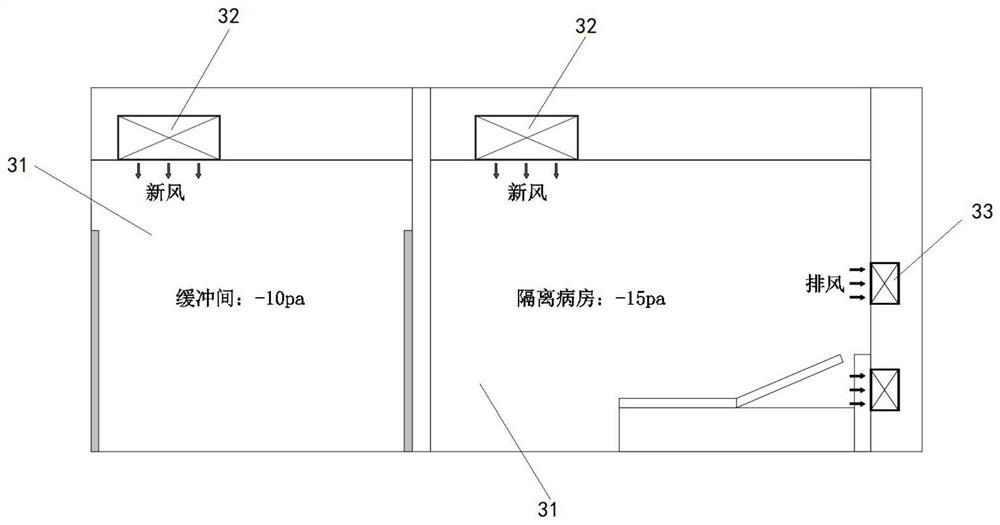

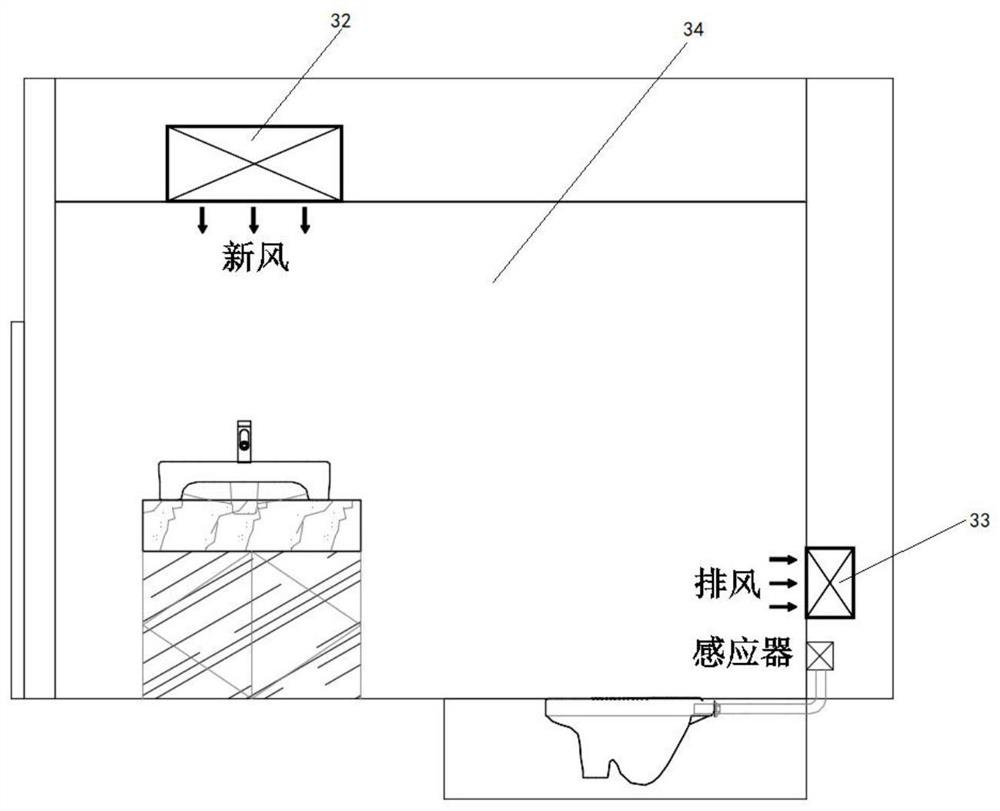

[0072] This embodiment also provides a modular assembly type hospital negative pressure isolation ward structure, including a frame built by metal composite boards and aluminum profiles, and a HVAC module, a decoration module, an electrical module, an intelligent module, and a medical gas module installed inside it. module and cabinet module; the HVAC module includes an air purification module, and the air purification module includes a buffer room and an isolation room inside the negative pressure isolation ward, and fresh air fans are installed in the buffer room and the isolation room near the entrance of the room, and the buffer room The air pressure in the isolation room is 10pa lower than that of the outside world, and the air pressure in the isolation room is 5pa lower than that in the buffer room. Two exhausts are installed on the side away from the entrance of the isolation room; the negative pressure isolation ward also includes a toilet, and a cleaning platform and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com