Three-dimensional visual robot intelligent inspection system for transformer substation

A technology of robot intelligence and inspection system, applied in instruments, computer parts, image data processing, etc., can solve the problems of imperfect diagnosis and early warning function, inability to coordinate data, and low visualization level, so as to improve the visualization level and improve diagnosis. The effect of early warning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

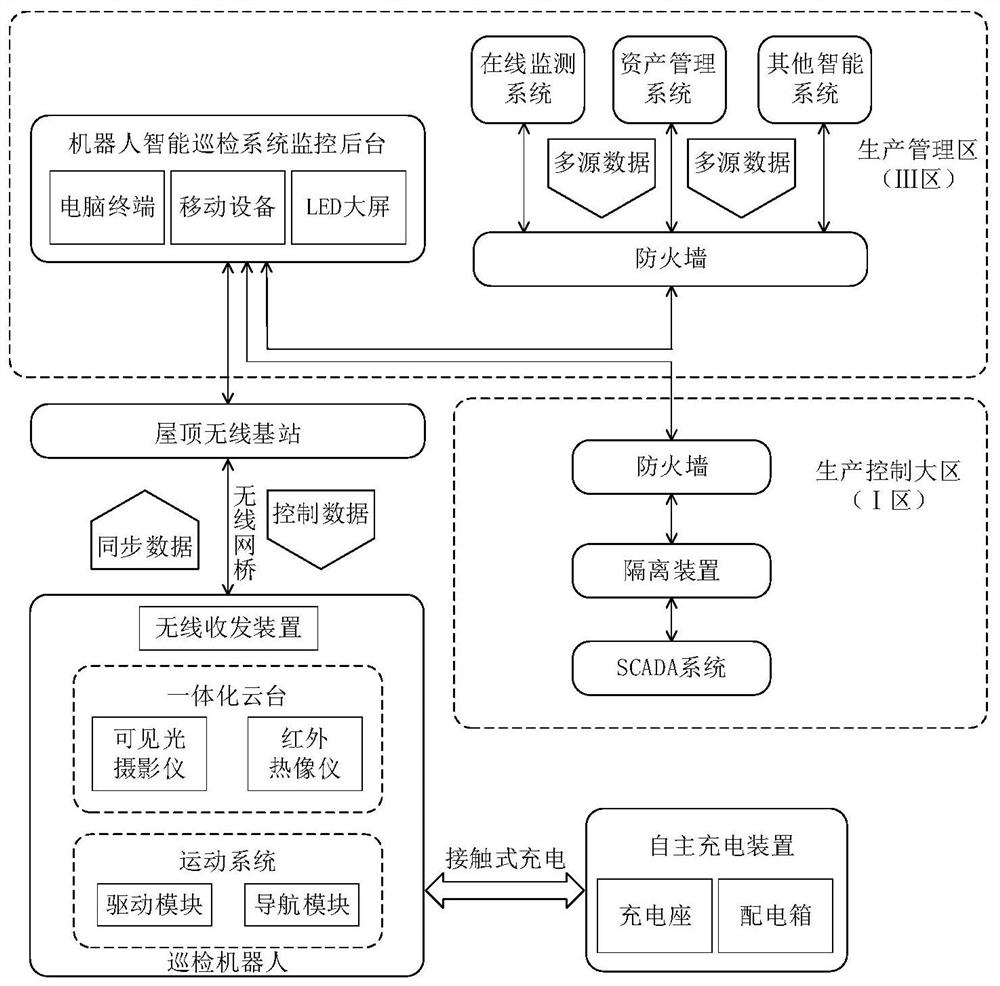

[0045] Such as figure 1 As shown, a substation three-dimensional visual robot intelligent inspection system includes: an inspection robot, a data transmission device, a self-service charging device, and a robot intelligent inspection system monitoring background, and the inspection robot is used to collect video images of the equipment to be tested Information, and the collected video image information is sent to the monitoring background of the robot intelligent inspection system through the data transmission device, and the data transmission device is used for uploading the data collected by the inspection robot and sending the monitoring background control data , the autonomous charging device is used for the automatic charging function of the inspection robot, and the monitoring background of the intelligent inspection system of the robot is used for storage, analysis, and display of inspection collection data.

[0046]In a specific embodiment, the background of the intell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com