High-strength bridge and assembling method thereof

A high-strength, bridge technology, used in electrical components, springs/shock absorbers, vibration suppression adjustment, etc., can solve the problems of safety, easy to break, easy to damage, etc., to achieve rapid combined installation, easy to clamp and fix , Easy to operate and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

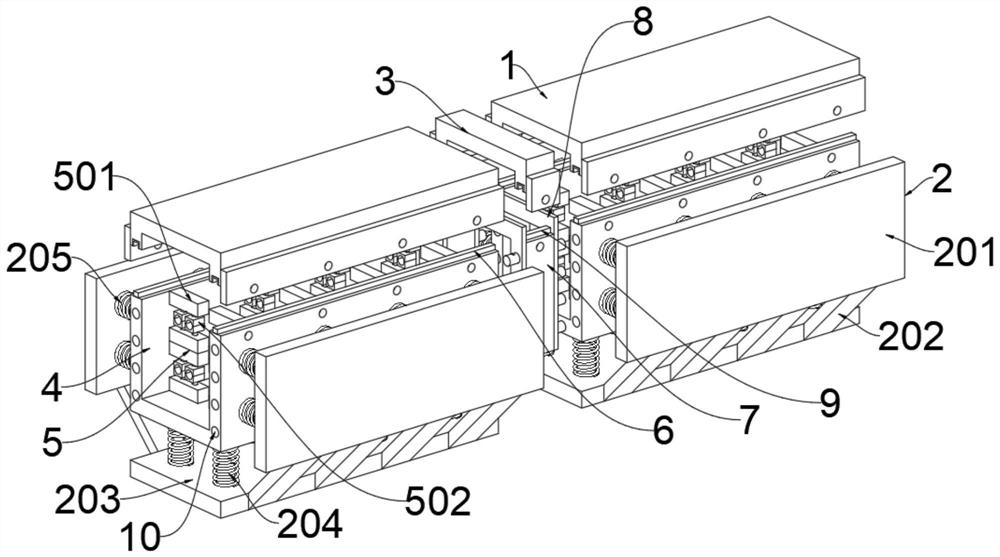

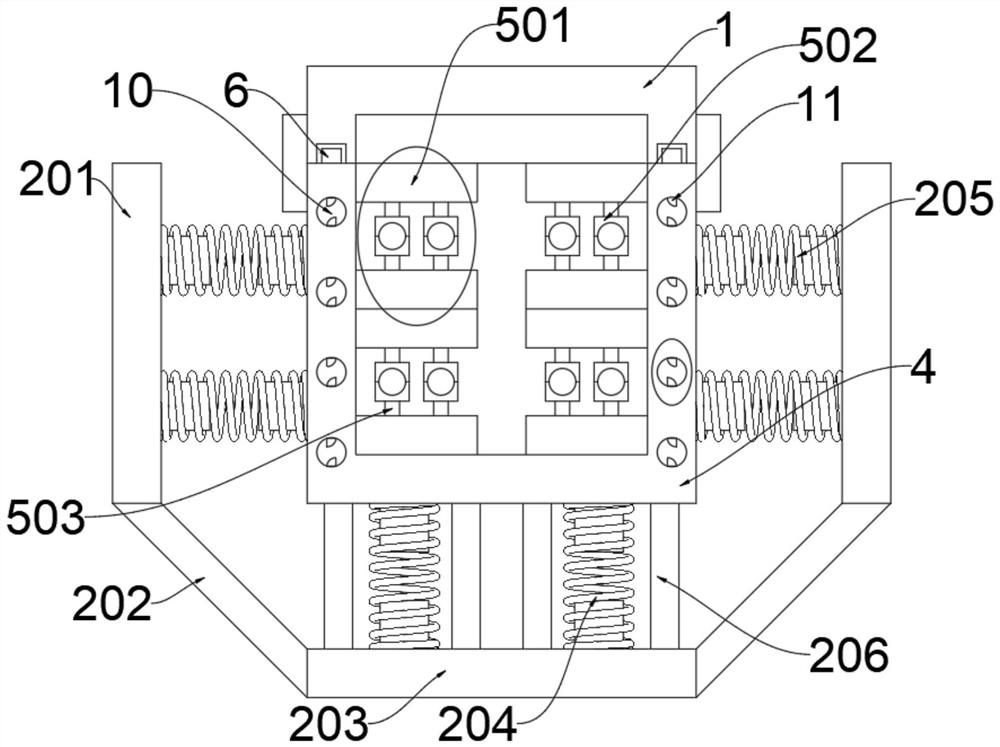

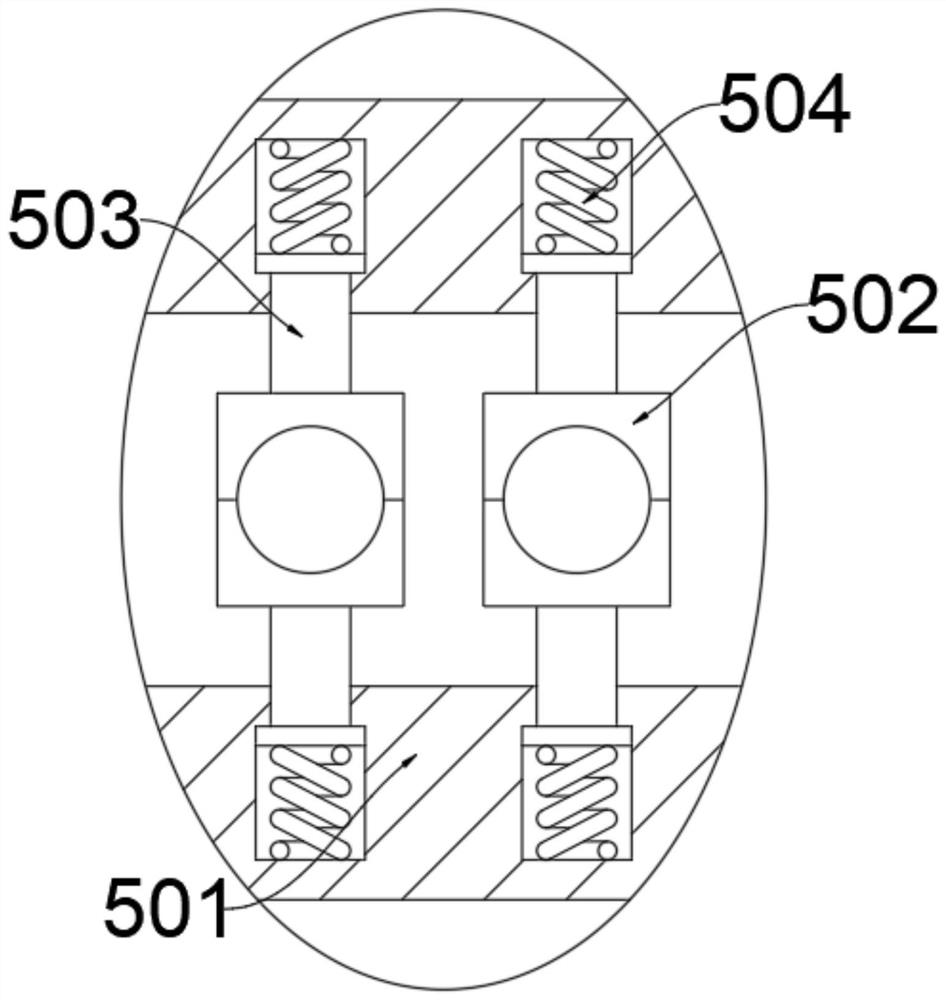

[0034] see Figure 1 to Figure 6 , an embodiment provided by the present invention: a high-strength bridge, including a bridge main shell 4, a number of cable fixing and clamping mechanisms 5 are evenly fixed on the inner side of the bridge main shell 4, and the cables can be arranged in an orderly manner. Clamping and fixing to avoid entanglement between cables and mutual interference. The upper end of the main housing 4 of the bridge frame is evenly fixed with two positioning rods 6, and a protective top cover 1 is movable above the two positioning rods 6. The bridge frame The outer side of the main housing 4 is provided with a shock absorbing mechanism 2, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com