Plane soft body pneumatic driver of array type series-parallel structure

A driver and array technology, applied in the direction of program control manipulators, manufacturing tools, manipulators, etc., can solve the problems of poor space bending ability, less research on pneumatic drivers, etc., and achieve the effect of good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with specific embodiments, but the protection scope of the present invention is not limited thereto.

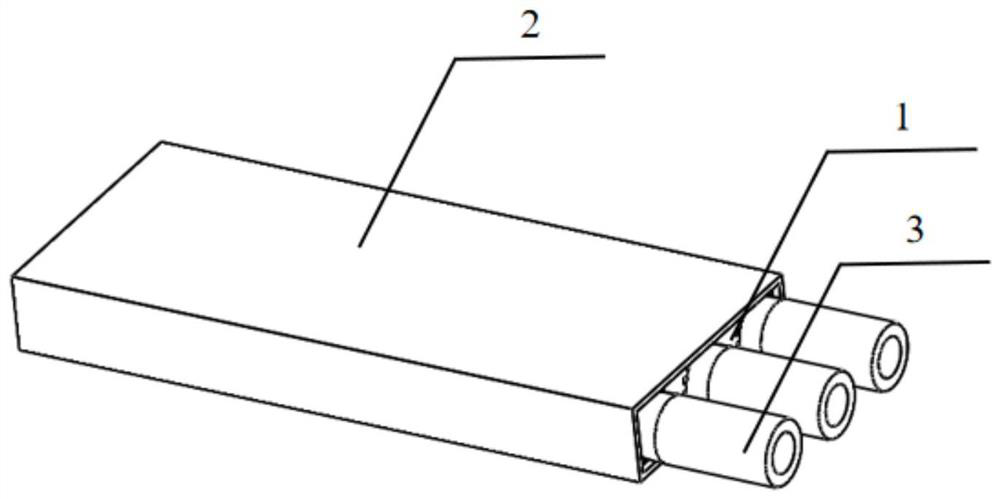

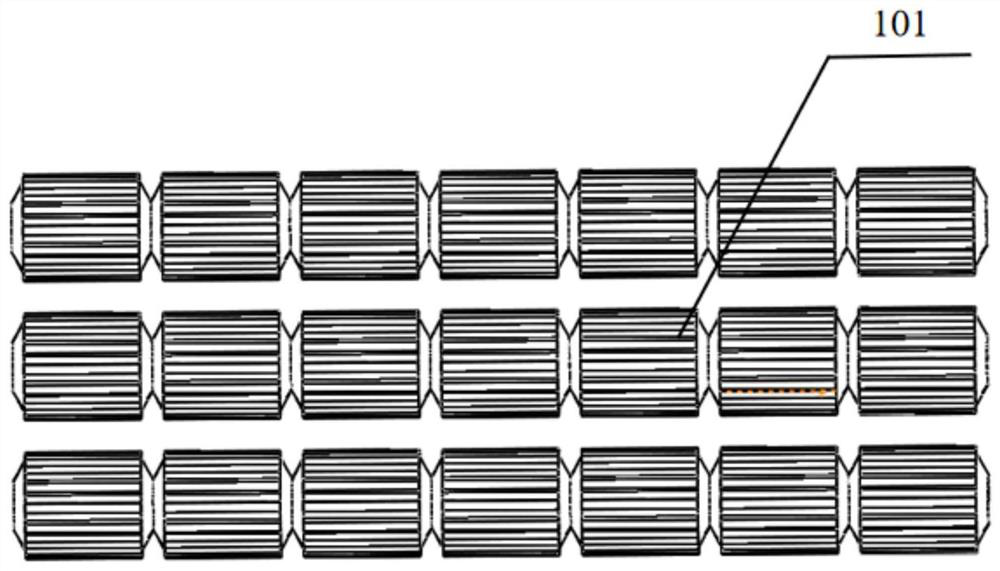

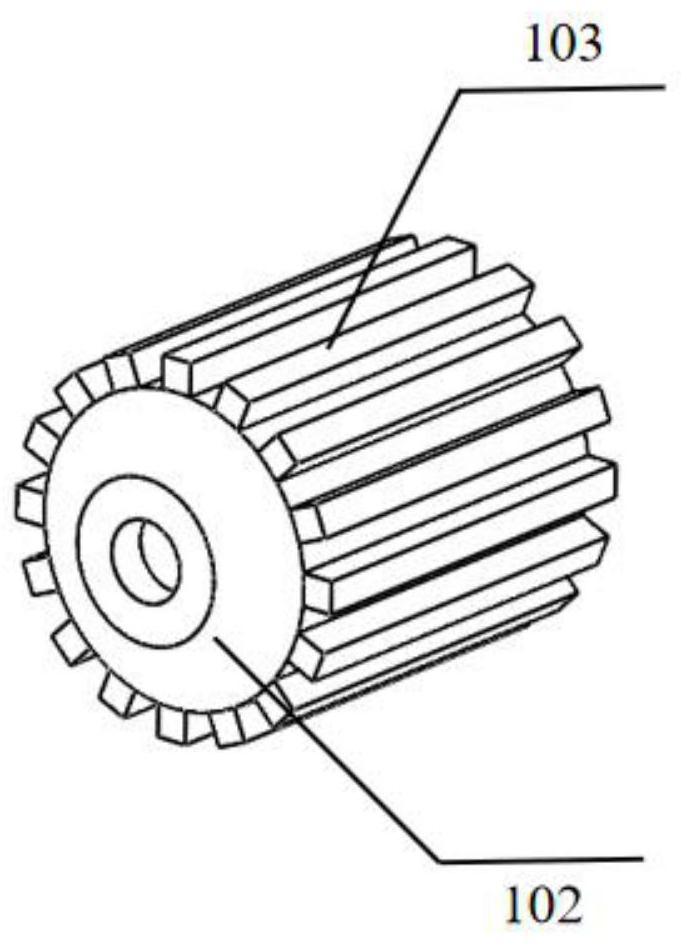

[0023] A planar software pneumatic driver with an array series-parallel structure, which is divided into the following three parts according to the functional structure: the drive module 1, the outer planar module 2, and the outer air circuit connection module 3, and the three parts are fixed by gluing, such as figure 1 shown. Wherein, the drive module 1 includes several long cylindrical drivers 101 arranged in parallel, such as figure 2 As shown; the outer plane module 2 includes upper and lower surfaces 201, side surfaces 202, and front and rear surfaces 203, such as Figure 5 As shown; the external air path connection module 3 is located at one end of the long cylinder driver 101 . The long cylindrical driver 101 is composed of several driving units 102 connected in series, and the driving uni...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap