A method for preparing nucleotides by a two-phase enzymatic hydrolysis system

A two-phase water-phase system and two-phase water-phase technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, hydrolytic enzymes, etc., can solve the problems of low recovery and utilization rate of nuclease P1, many process steps, and difficult bioprocessing, etc. problem, to achieve the effect of improving the enzymatic hydrolysis rate of nucleotides and the yield of finished products, improving the recovery rate of enzymes, and being easy to scale up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

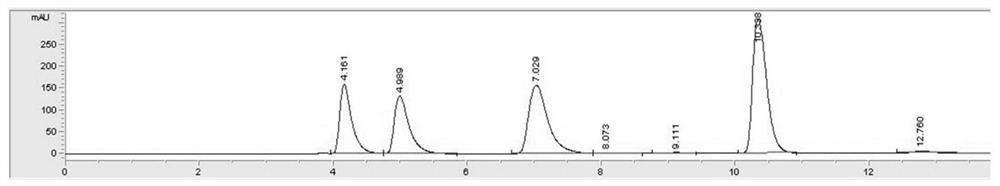

Image

Examples

Embodiment 1

[0052] In the two-phase enzymolysis tank, add 2kg polyethylene glycol 2000, 1.2kg ammonium sulfate, add 0.4kg ribonucleic acid, 0.02kg zinc chloride, add deionized water to a total system weight of 10kg, polyethylene glycol / In the ammonium sulfate system, the concentration of polyethylene glycol 2000 is 20% (w / w), the concentration of ammonium sulfate is 12% (w / w), the pH is adjusted to 6.0, the temperature is raised to 65°C, and stirred until fully dissolved. Add 0.6L of nuclease P1 (3000U / mL) to start the enzymatic hydrolysis, which ends after 4 hours, and the reaction solution is allowed to stand for 2 hours to form two phases. The upper phase contains nuclease P1 with a volume of 4.8L, the detected enzyme activity is 346U / mL, and the recovery rate of the enzyme activity is 92.27%. The volume of the lower phase is 5.6L, the nucleotide concentration is 48.86g / L, and the enzymolysis rate is 68.4%. Emit the lower phase aqueous solution, adopt the molecular weight cut-off tha...

Embodiment 2

[0054] In the two-phase aqueous enzymolysis tank, add 2.4kg polyethylene glycol 2000, 1.8kg ammonium sulfate. Add 0.5kg ribonucleic acid again, 0.03kg zinc chloride, add deionized water to total system weight and be 10kg, in polyethylene glycol / ammonium sulfate system, polyethylene glycol 2000 concentration is 24% (w / w), sulfuric acid The ammonium concentration was 18% (w / w), the pH was adjusted to 5.5, the temperature was raised to 70°C, and stirred until fully dissolved. Add 0.5 L of nuclease P1 (2500 U / mL) to start the enzymatic hydrolysis, which ends after 5 hours. The reaction solution was left to stand for 2h to form two phases. The upper phase contains nuclease P1 with a volume of 4.6L, the detected enzyme activity is 263U / mL, and the recovery rate of the enzyme activity is 96.78%. The volume of the lower phase is 5.9L, the nucleotide concentration is 64.07g / L, and the enzymolysis rate is 75.6%. Release the lower phase aqueous solution, and use an ultrafiltration m...

Embodiment 3

[0056] In the two-phase aqueous enzymolysis tank, add 1.6kg polyethylene glycol 2000, 2.4kg ammonium sulfate. Then add 0.8kg ribonucleic acid, 0.05kg zinc chloride, and supplement deionized water until the total system weight is 10kg. In the polyethylene glycol / ammonium sulfate system, the concentration of polyethylene glycol 2000 is 16% (w / w), and the concentration of ammonium sulfate is 24% (w / w). Adjust the pH to 6.5, raise the temperature to 75°C, stir until fully dissolved, add 0.5L of nuclease P1 (4000U / mL), start enzymatic hydrolysis, and end after 7h, let the reaction solution stand for 2h to form two phases. The upper phase contains nuclease P1 with a volume of 3.8L, the detected enzyme activity is 464U / mL, and the recovery rate of the enzyme activity is 88.2%. The volume of the lower phase is 6.7L, the nucleotide concentration is 79.28g / L, and the enzymolysis rate is 66.4%. Emit the lower phase aqueous solution, and use an ultrafiltration membrane with a molecular ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com