Drop test machine

A testing machine and adjustment mechanism technology, applied in impact testing, testing of machine/structural components, measuring devices, etc., can solve problems such as low testing efficiency and inconvenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

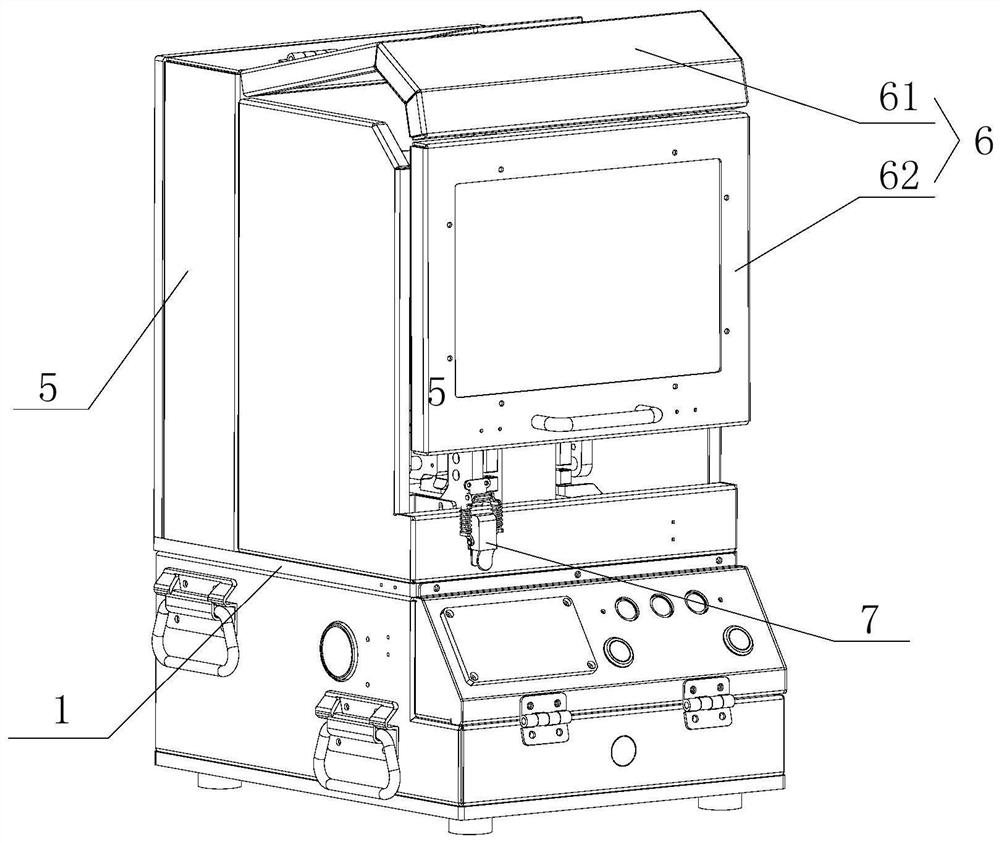

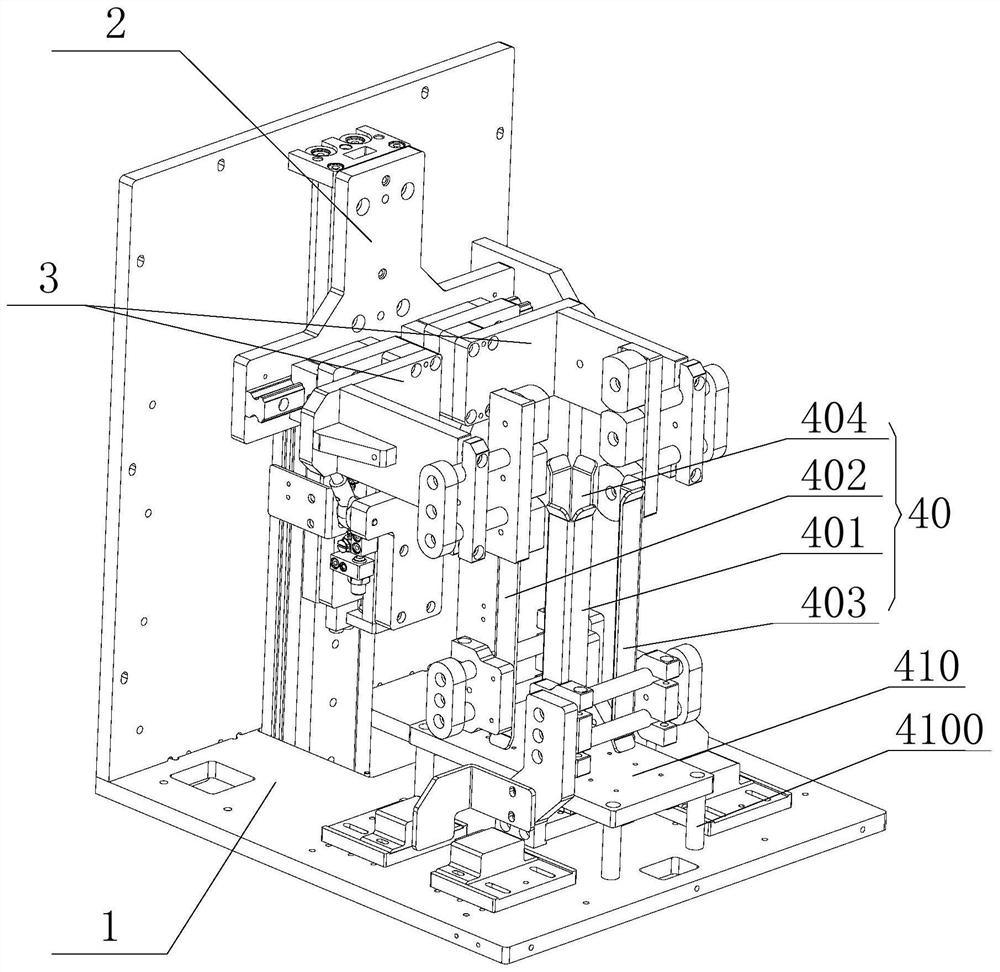

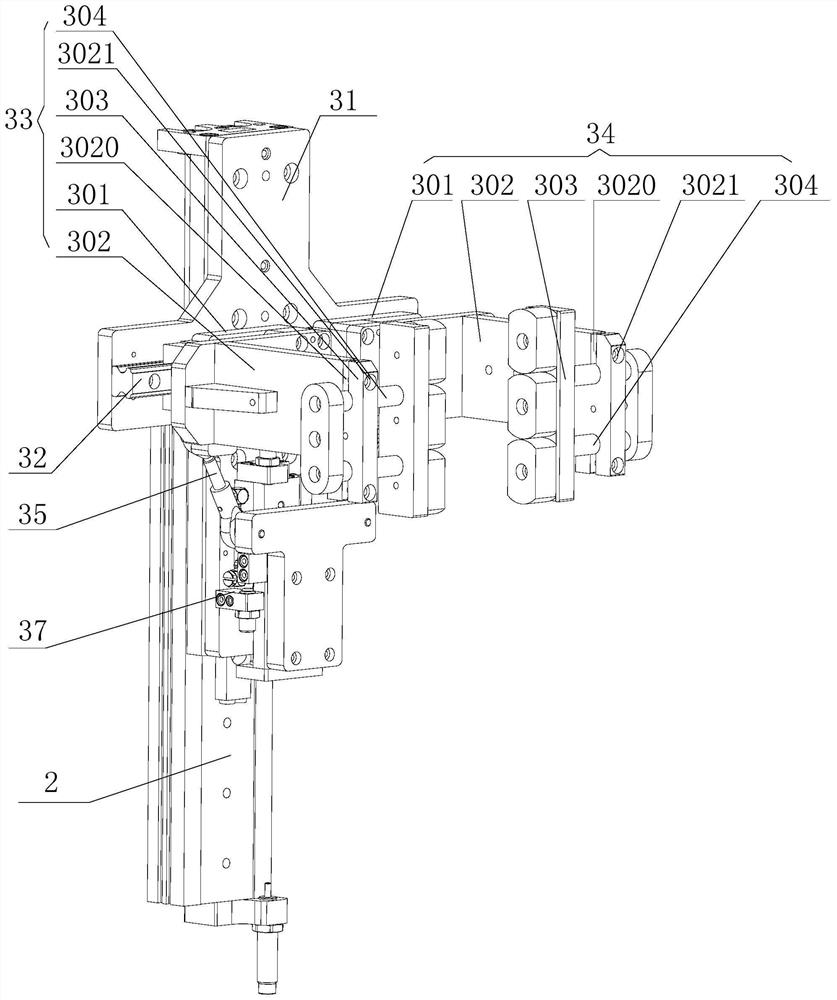

[0051] The present embodiment provides a kind of drop testing machine, refer to Figure 1 to Figure 3 , the drop test machine includes a base 1, a lifting device 2, a clamping device 3 and an enclosure device; the clamping device 3 is installed on the lifting device 2, and is configured to be able to clamp or release the package; the lifting device 2 is installed on the base 1; the enclosure device includes a plurality of longitudinal enclosures connected to the base 1 at the position below the clamping device 3 , and surrounded by a plurality of longitudinal enclosures to form a fence 40 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com