Density segmented correction method and online moisture content monitoring method for online moisture content analysis of multi-component oil product

A multi-component, water content technology, applied in the use of microwave to test water content, analysis of materials, material analysis by electromagnetic means, etc., can solve the problem of difficult tracking of oil components, and achieve real-time high reliability and efficiency High, accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

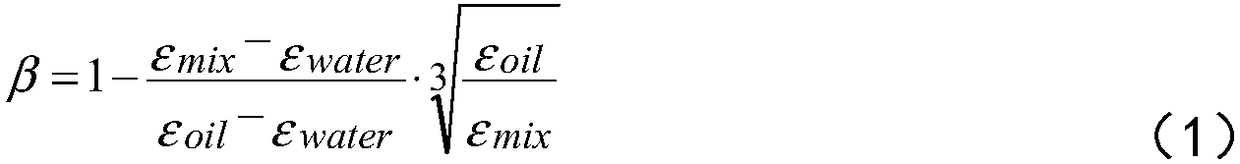

Method used

Image

Examples

Embodiment

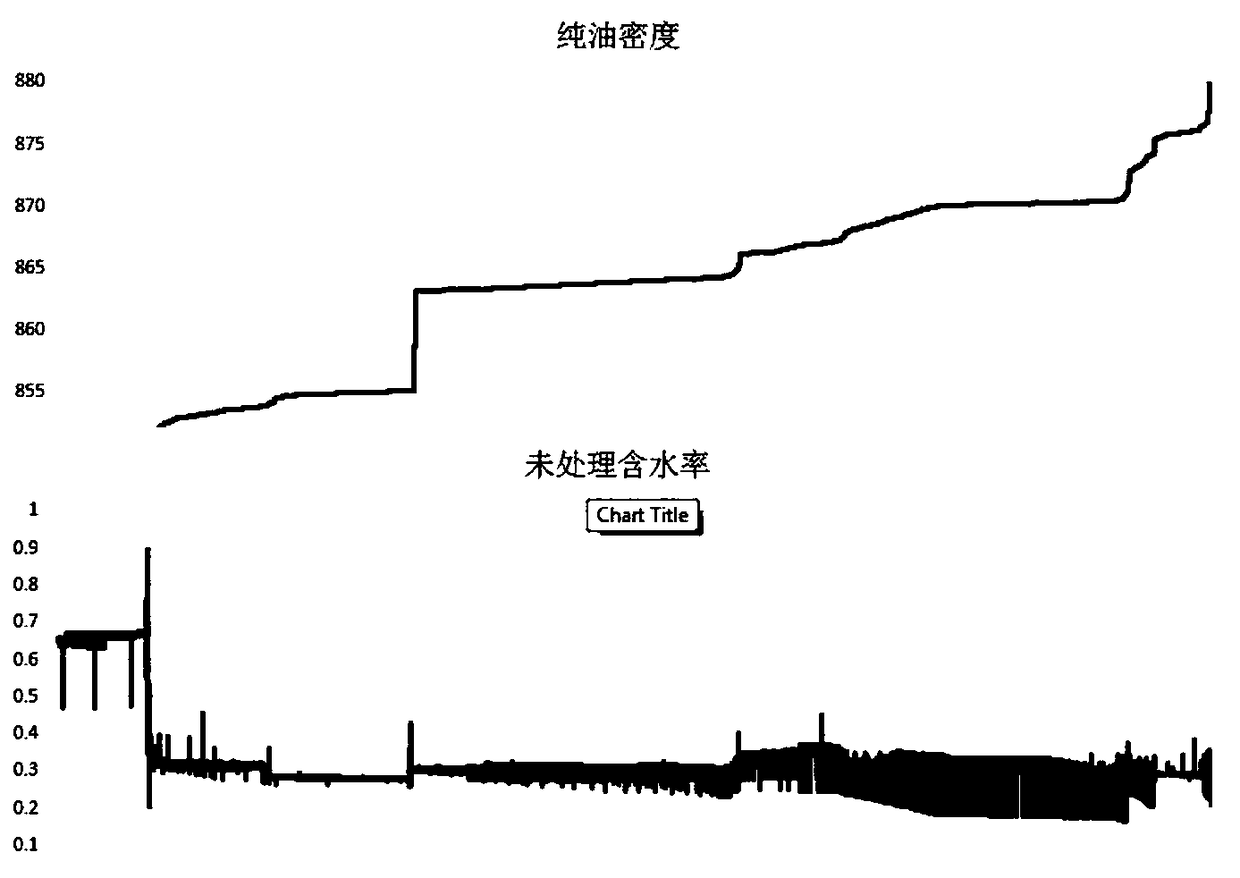

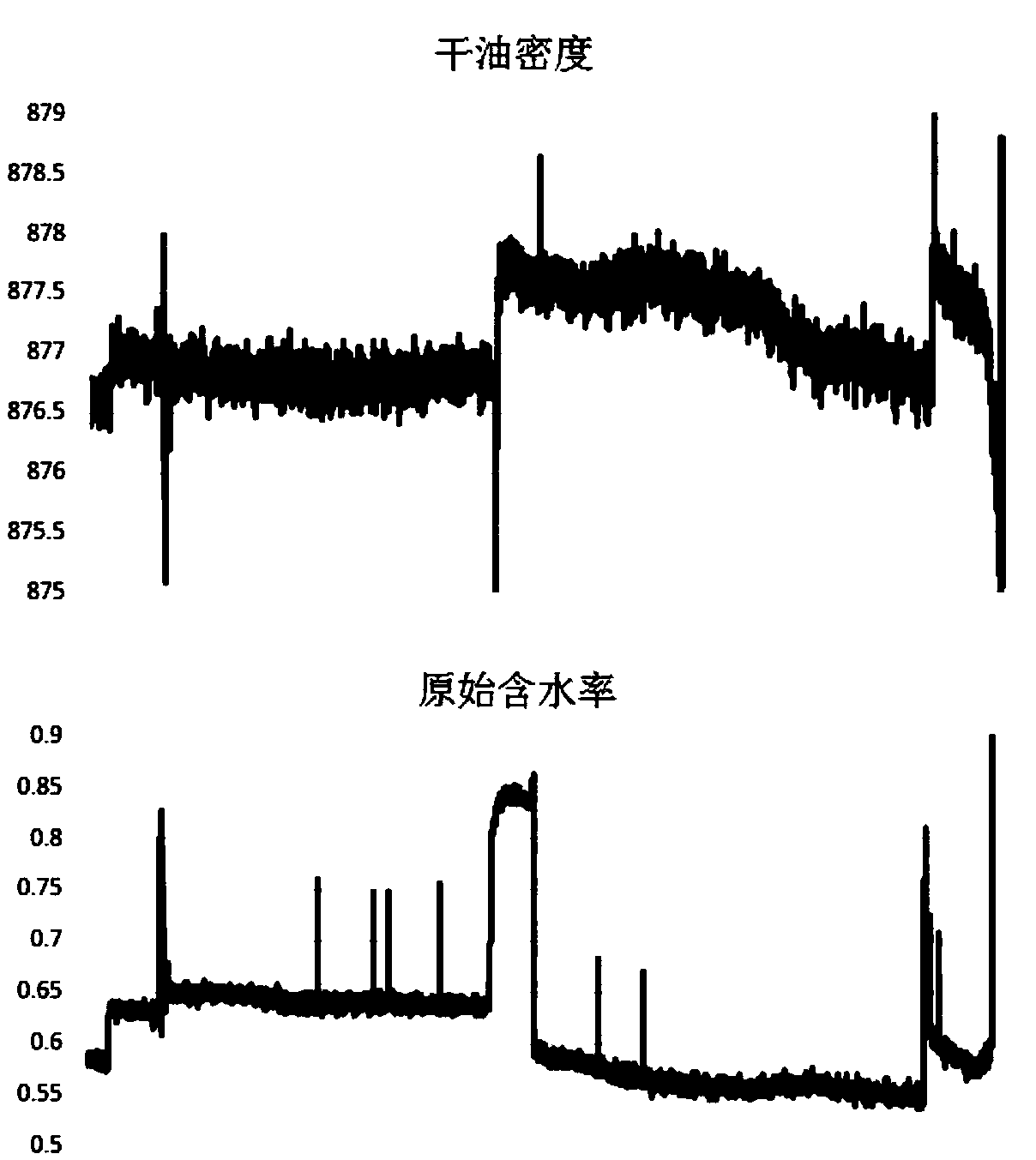

[0081] An on-line water content monitoring method for multi-component oil products, through the automatic zeroing technology and the use of density segmentation correction method, the crude oil density with a wide range of fluctuations is divided into several sub-density intervals, and each sub-density interval has its own deviation correction Coefficient; automatically find the corresponding sub-density interval through the oil density value, and call the correction deviation coefficient of different sub-density intervals according to the different density values to eliminate the influence of oil component changes and oil-water distribution forms on the measurement results , to ensure the accuracy of the moisture content value obtained under ultra-low moisture content.

[0082] figure 1 and figure 2 This is the graph of measurement results obtained after applying the above method to two sites of Zhenhai Refining and Chemical Company, figure 1 The density of medium and pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com