Flaw detection bracket and ultrasonic flaw detector

A sliding frame and hanger technology, which is applied in the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis and instruments using sound waves/ultrasonic waves/infrasonic waves, and can solve potential safety hazards and threats to urban rail transit safety. The effect of bump damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

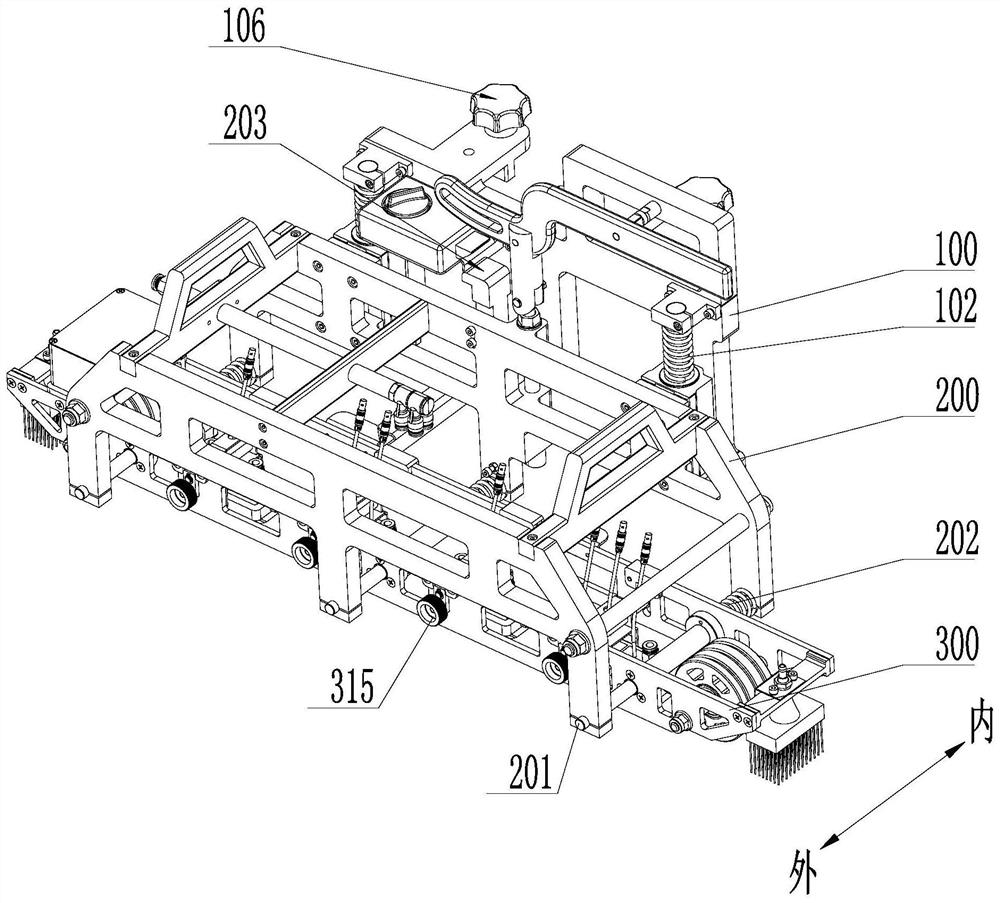

[0050] Such as Figure 1-Figure 14 As shown, this embodiment provides a flaw detection bracket, including a hanger assembly 100, a carriage assembly 200 and a shoe probe assembly 300,

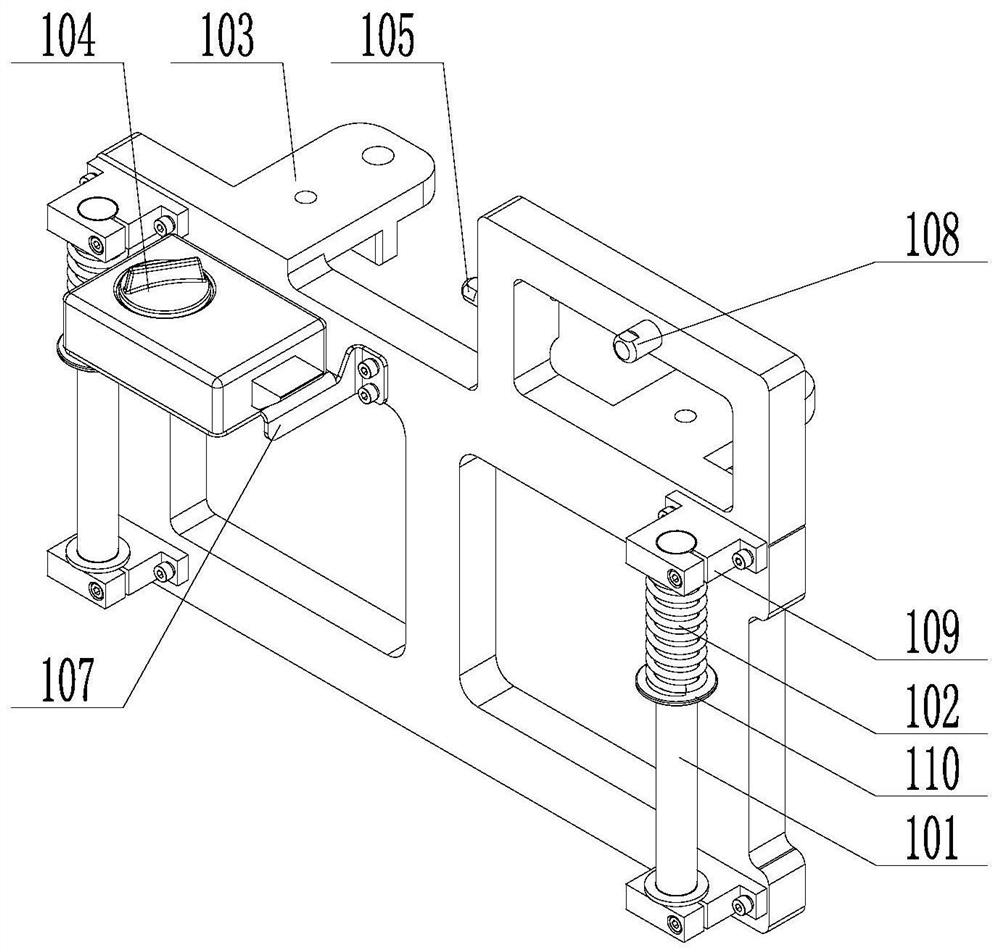

[0051] The hanger assembly 100 includes at least one hanger guide assembly, the hanger guide assembly includes a guide shaft 101 and a first spring 102, and the guide shaft 101 is vertically arranged;

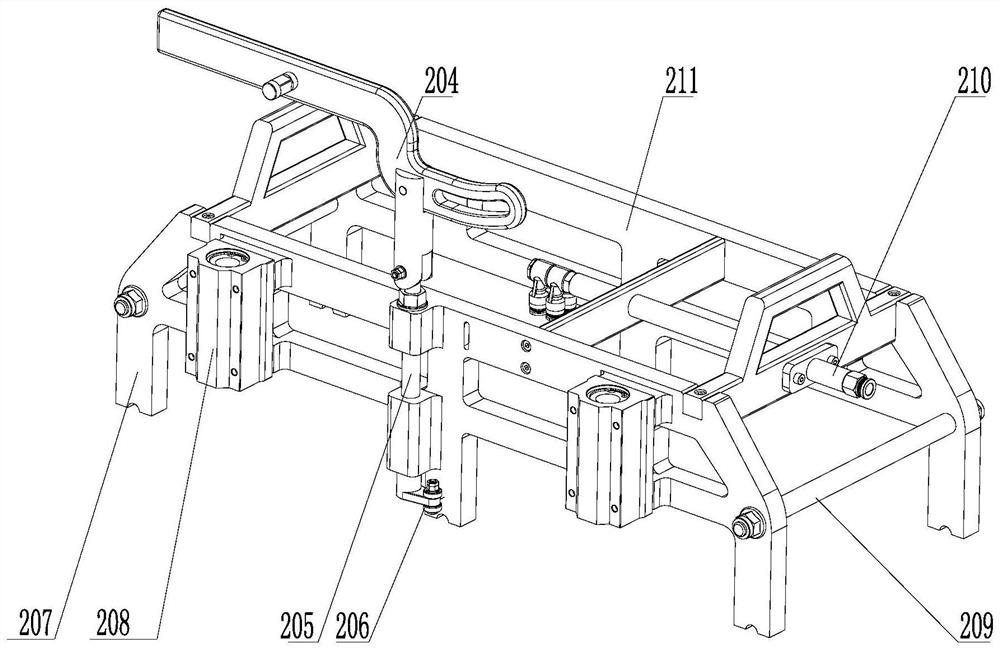

[0052] The carriage assembly 200 includes a carriage plate assembly and at least one carriage guide assembly, the first spring 102 and the carriage plate assembly are sheathed on the guide shaft 101, and the first spring 102 is opposite to the guide shaft 101. The carriage plate assembly applies a downward force, the carriage guide assembly includes a guide shaft 201 and a secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com