A small die-casting waste cleaning mechanism

A die-casting and die-casting machine technology, which is applied in the field of small-scale die-casting waste cleaning mechanisms, can solve the problems of rising costs and low output, and achieve the effects of quality assurance, simple structure, and improved efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings of the description.

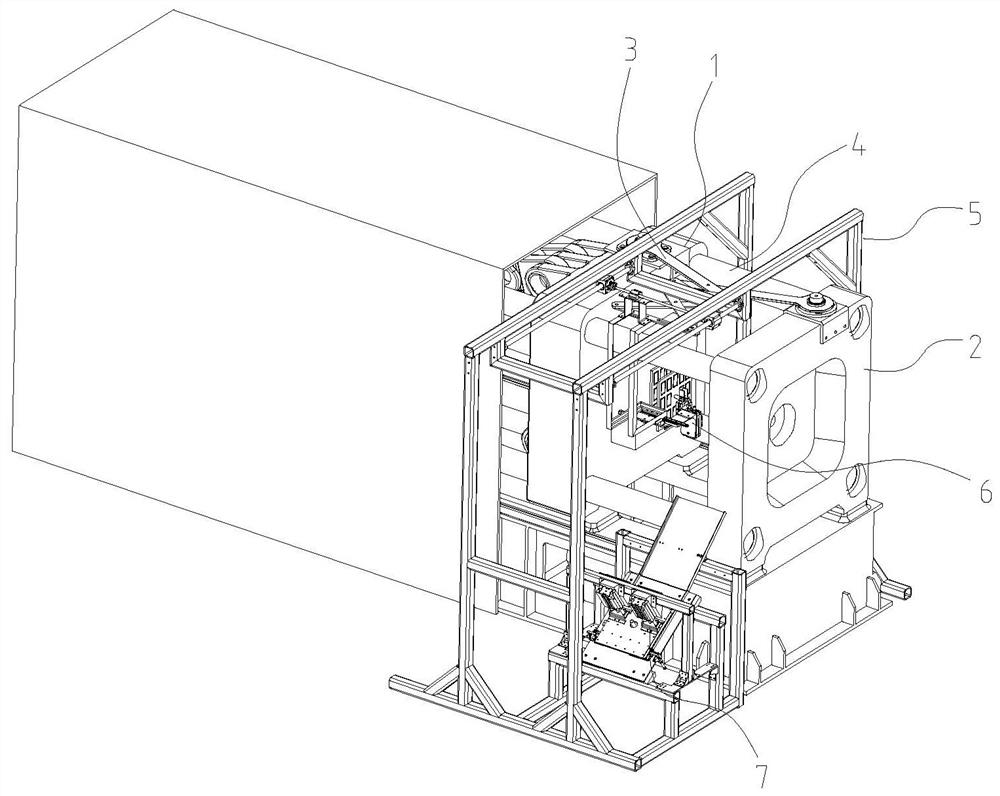

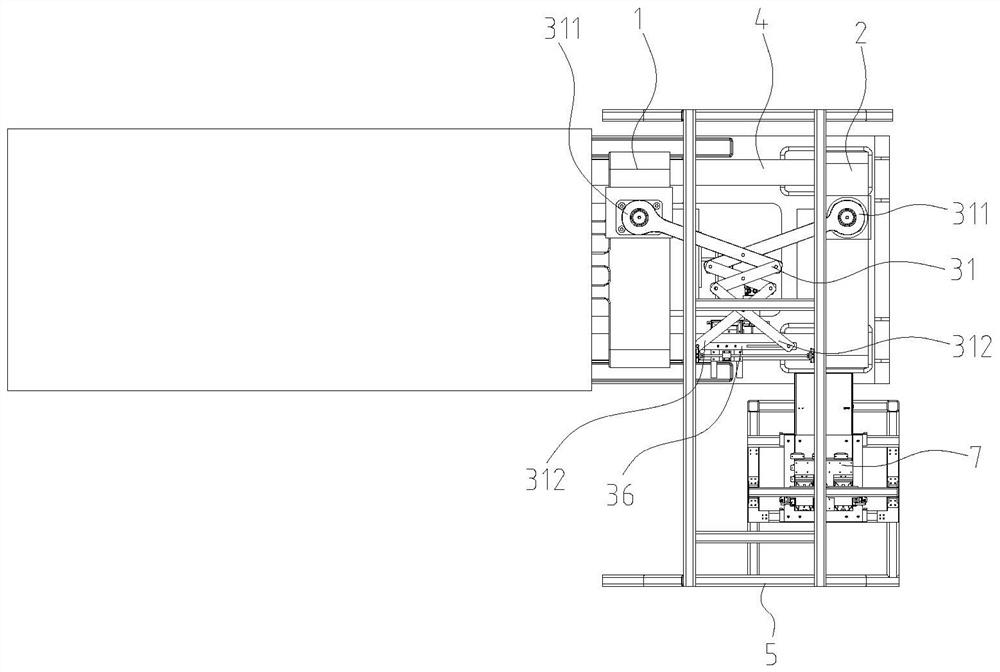

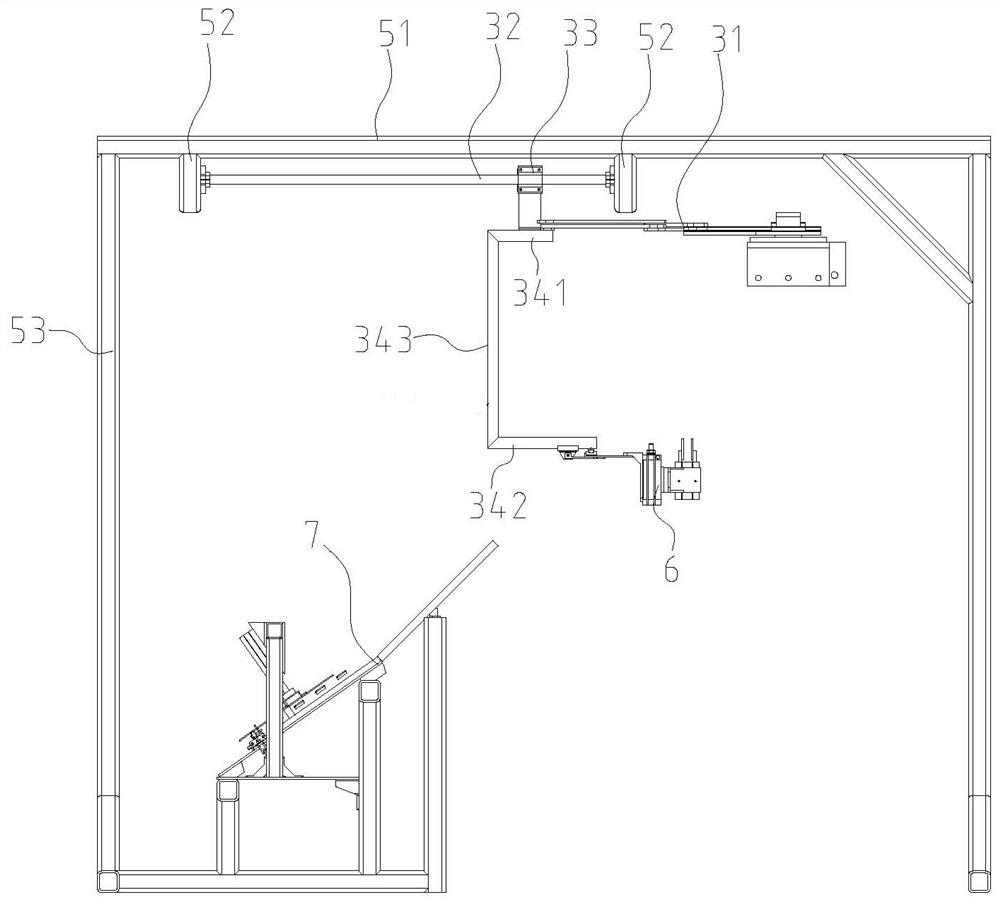

[0024] Such as figure 1 , 2 As shown, a small-scale die-casting waste cleaning mechanism includes a die-casting machine middle plate 1, a die-casting head plate 2 formed in cooperation with the die-casting machine middle plate 1, and a die-casting head plate 2 arranged between the die-casting machine middle plate 1 and the die-casting head plate 2 The telescopic linkage mechanism 3, the pick-up mechanism 6 located on the telescopic linkage mechanism 3, the waste material cleaning mechanism 7 and the mounting frame 5 docked with the pick-up mechanism 6.

[0025] Four guide columns 4 are arranged between the die-casting machine middle plate 1 and the die-casting head plate 2, and the die-casting machine middle plate 1 can approach or move away from the die-casting head plate 2 along the guide columns 4, thereby realizing the die-casting of the workpie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com