A multi-heat storage tank type heat storage phase change heat exchanger with diversion function

A technology of phase-change heat exchanger and heat storage tank, which is applied in the direction of indirect heat exchanger, heat exchanger type, heat exchanger shell, etc., can solve the problems of poor sealing and water resistance, bulkiness, etc., and achieve convenience Equipment energy consumption, stable and accurate installation, easy to reduce the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

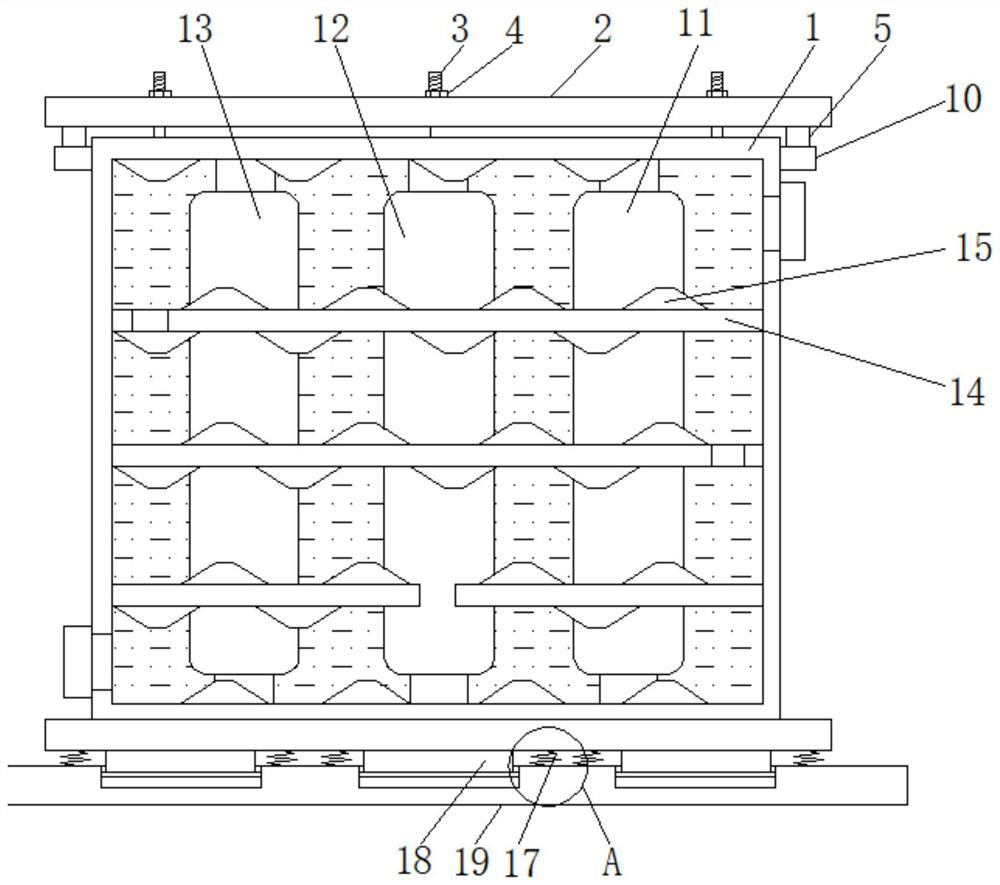

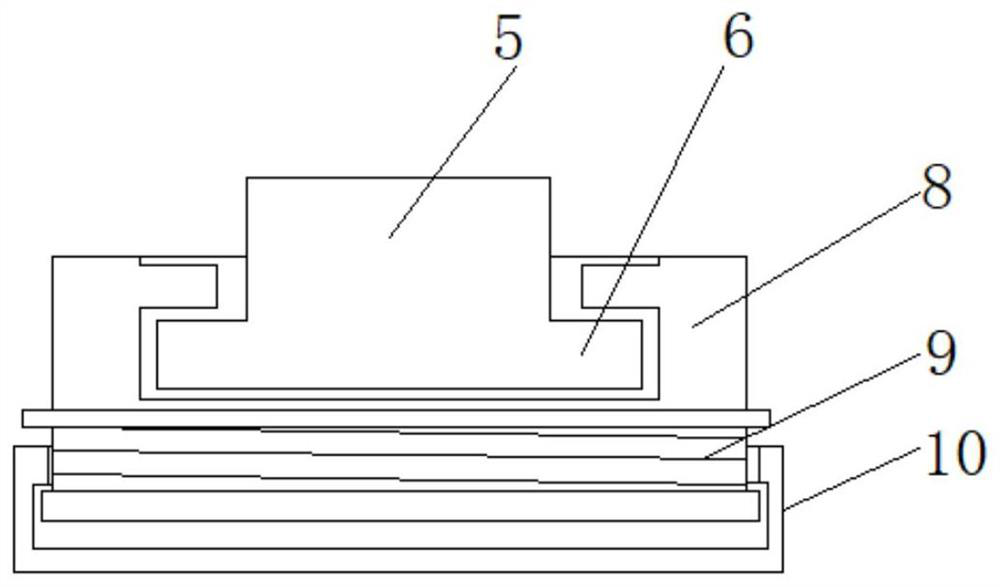

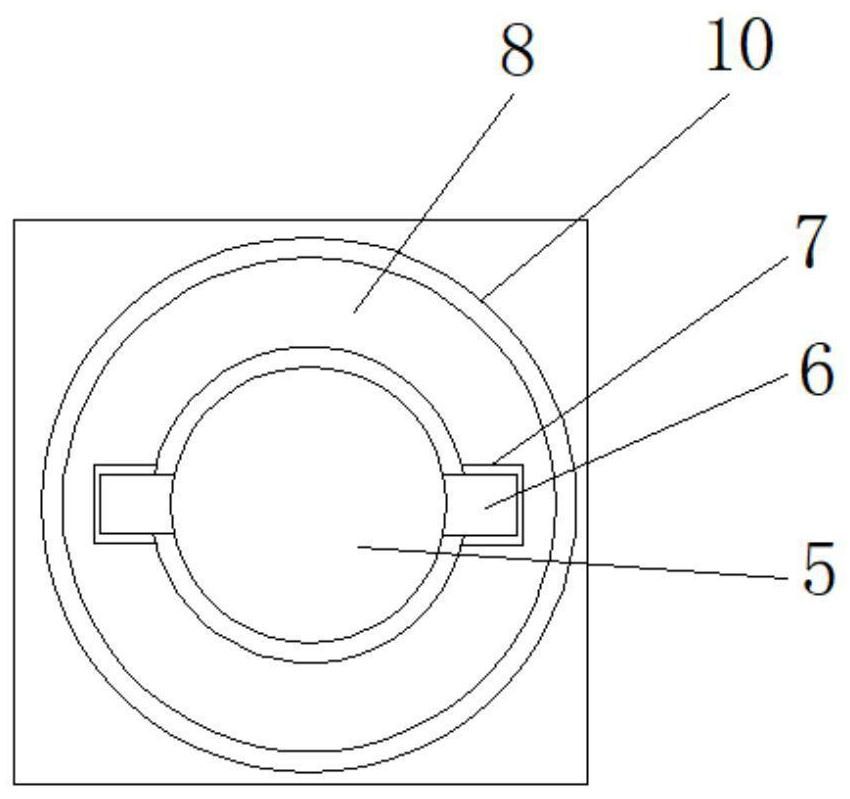

[0019] see Figure 1-5 , this implementation provides a technical solution:

[0020] A heat storage phase-change heat exchanger with multiple heat storage tanks and diversion function in this embodiment, including a main body 1, a top cover 2, a fixing rod 3, a nut 4, a connecting rod 5, a block 6, and an assembly groove 7. Connecting piece 8, threaded piece 9, fixing block 10, first heat storage tank 11, second heat storage tank 12, third heat storage tank 13, diversion layer 14, bump 15, bolt 16, spring 17, The limit frame 18 and the base 19, the top of the main body 1 is provided with a top cover 2, and the inside of the top cover 2 is penetrated with a fixed rod 3, and the periphery of the fixed rod 3 is penetrated with a nut 4, and the bottom of the top cover 2 is provided with a connection rod 5, and the outside of the connecting rod 5 is provided with a block 6, and the outside of the block 6 is connected with an assembly groove 7, the outside of the block 6 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com