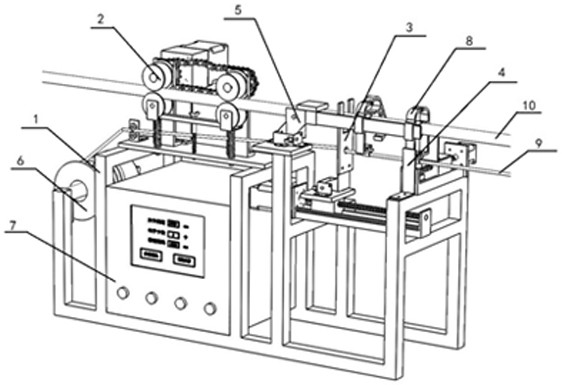

Overhead transmission line blasting deicing detonating cord automatic laying device and using method thereof

A technology for overhead transmission lines and overhead transmission lines, which is applied in the directions of overhead lines/cable equipment, overhead installation, cable installation, etc., can solve problems such as difficulty in laying detonating cords, and achieve the effect of improving laying efficiency and eliminating potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

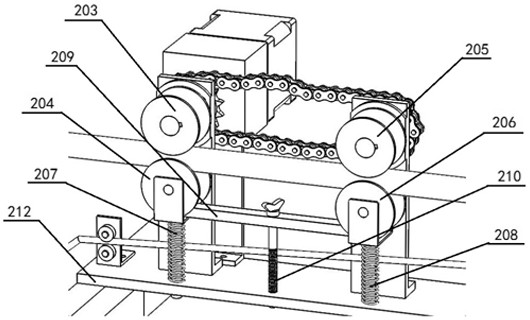

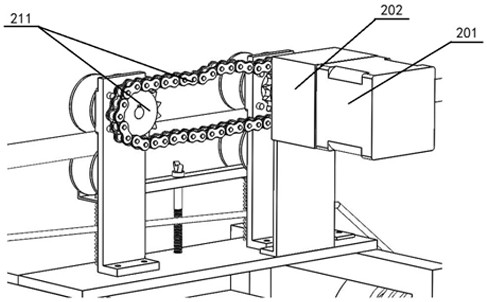

[0030] The present invention will be further explained with reference to the drawings.

[0031] Suppose there are 3 detonating cord clamping fixtures, the distance between detonating cord clamping fixtures is 1000mm, and the distance between the first detonating cord clamping fixture (the furthest detonating cord clamping fixture) and the transmission tower is 4000mm. The steps are as follows:

[0032] 1. The operator rotates the 90-degree self-locking folding hinge hinge Ⅱ501 on the detonating cord clamping fitting installation guide mechanism 5 by 90 degrees counterclockwise to turn the entire installation guide mechanism 5 downward, and the 90-degree self-locking mechanism of the push mechanism 3 The locking and folding hinge hinge I303 rotates 90 degrees counterclockwise to make the push plate 304 lie down and make room for placement.

[0033] 2. Turn the locking bolt 210 clockwise. Under the action of the pre-tightening force of the locking bolt 210, the lower pressing plate 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com