Adjustable bed guardrail supporting structure

A support structure and adjustable technology, applied in the field of bed guardrails, can solve the problems of poor stability and firmness of bed guardrails, easy loosening, poor versatility, etc., achieve good stability and firm reliability, reduce structure and size requirements, Improve the effect of the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

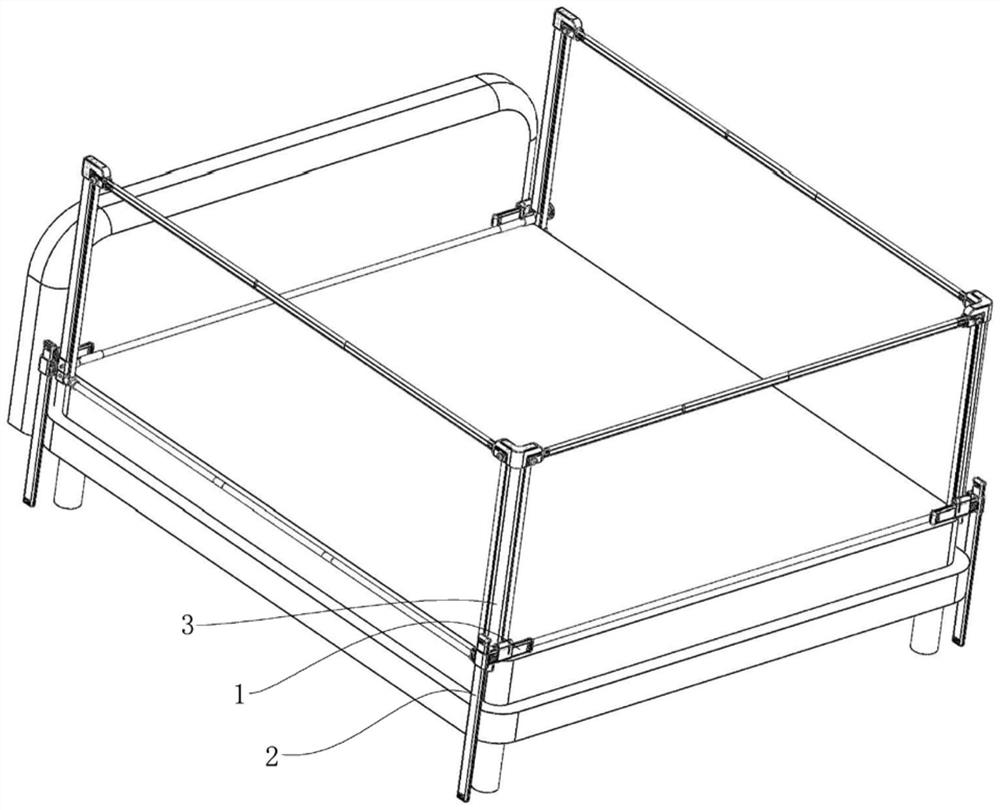

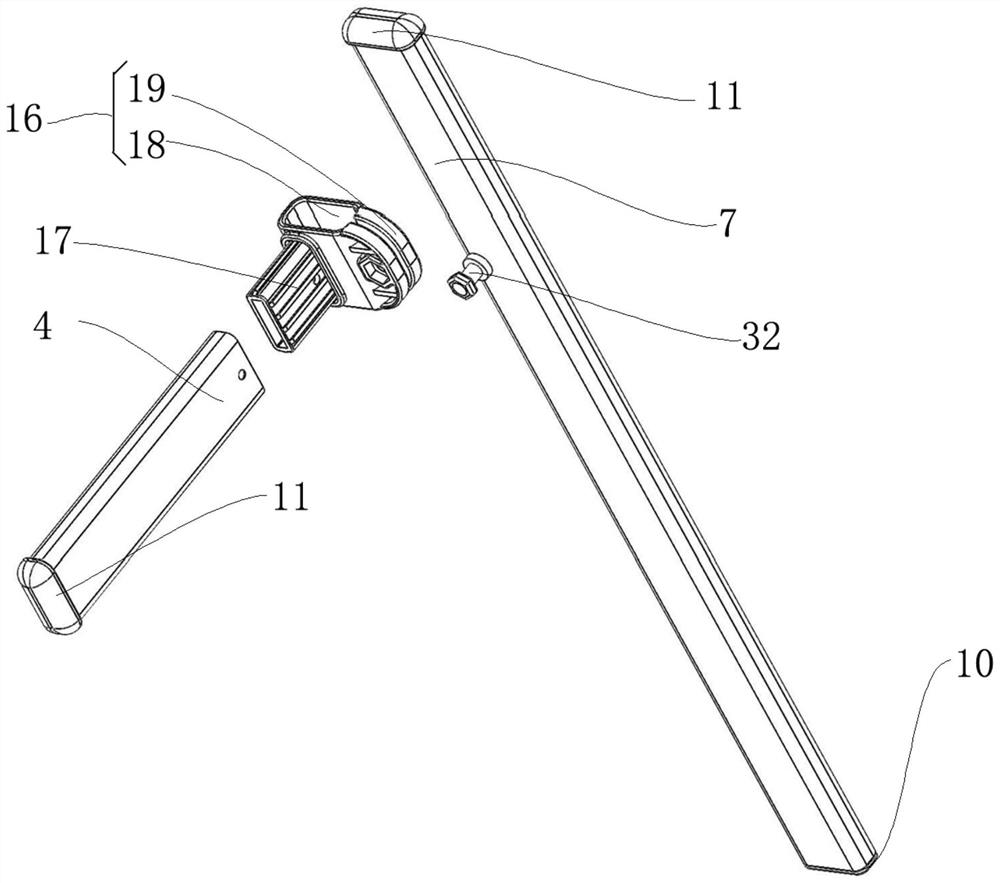

[0033] like Figure 1-7 As shown, it includes: a horizontal adjustment part 1, a vertical adjustment part 2 and a guardrail bracket part 3; the horizontal adjustment part 1 includes a horizontal support rod 4 and a horizontal sleeve device 5, and the horizontal support rod 4 can be movably sleeved on the horizontal sleeve device. 5, and the transverse strut 4 can be fixed in position by the transverse sleeve device 5, specifically, as figure 2 As shown, the horizontal strut 4 and the following vertical strut 7 are rectangular aluminum alloy rods with rounded edges;

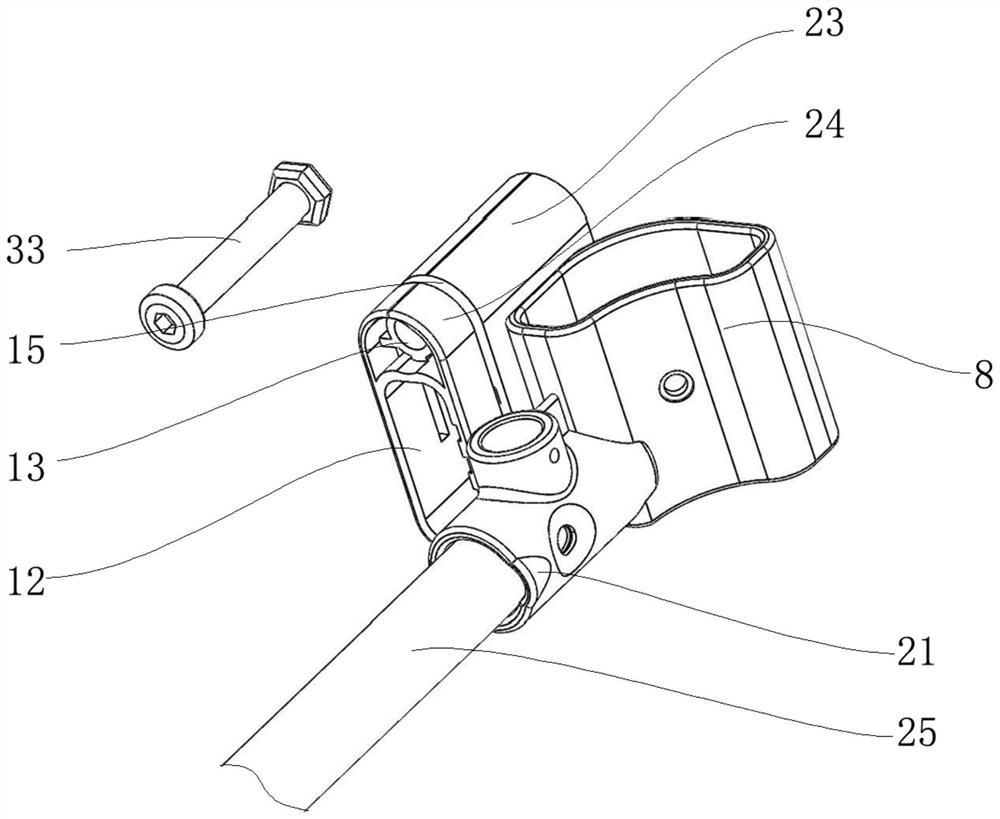

[0034] Moreover, in the present embodiment, the transverse sleeve device 5 includes a transverse sleeve 12 and a first fixing device 13 arranged on the side of the transverse sleeve 12, and a fastening device 13 is passed between the first section 23 and the second section 24. Specifically, the transverse sleeve device 5 also supports and fixes the transverse strut 4. After the transverse strut 4 is adjusted to ...

Embodiment 2

[0043] Compared with Embodiment 1, Embodiment 2 is based on Embodiment 1; both the horizontal sleeve device 5 and the vertical sleeve device 6 adopt a sleeve structure with fastening screws on the side, and the horizontal support rod 4 After the vertical strut 7 is adjusted to a proper position, the horizontal strut 4 and the vertical strut 7 socketed in the casing are directly fastened and fixed by fastening screws. This fixing method is simpler and more convenient.

Embodiment 3

[0045] like Figure 4 , Figure 5 As shown, compared with Embodiment 1, in this embodiment, the bottom of the vertical bar bottom cover 22 is provided with a concave rounded corner 28, and the concave rounded corner 28 abuts against the corner of the side edge of the mattress, that is, two adjacent surfaces Formed concave fillet 28, wherein the first surface 30 abuts against the upper surface of the mattress or the upper surface of the bed edge, wherein the second surface 31 abuts against the side of the mattress or the edge of the bed, and the second surface 31 and the side of the mattress may There will also be a little gap, the first sleeve 26 is arranged on the rounded side wall 29 of the concave fillet 28 where the second surface 31 is located, and the first sleeve 26 and the first pull rod 27 are arranged near the side wall of the mattress; In the above structural design, the second sleeve 21 and the second pull rod 25 are arranged on the upper part of the mattress, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com