Clamping device for machining reeling device

A technology of clamping device and force coiler, which is applied in the direction of workpiece clamping device and manufacturing tools, can solve the problems of vibration of force coiler, affecting the clamping effect, cleaning of sliding rod and slider, etc., so as to reduce vibration, Optimize the clamping process and improve the effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

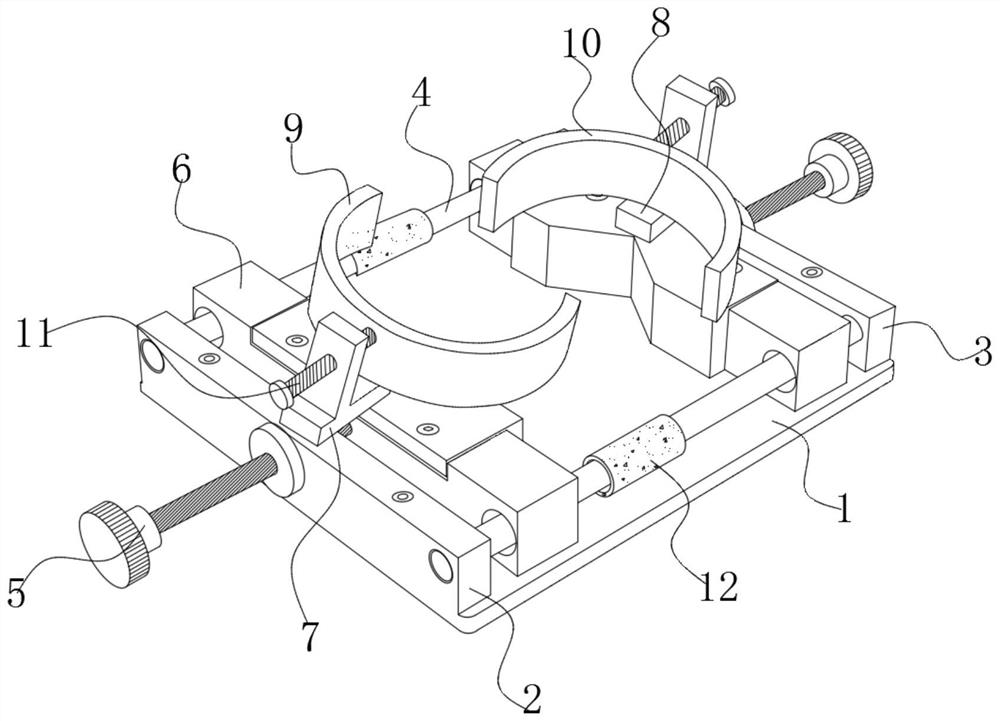

[0024] Such as Figure 1 to Figure 4 As shown, the present invention includes an underframe, and the underframe includes a base plate 1, a first base 2 and a third base 3, and the left and right sides of the upper surface of the base plate 1 are symmetrically fixed with the first base 2 and the second base 3, The central positions of the first base 2 and the second base 3 are respectively connected with a first threaded rod 5 placed horizontally, and the ends of the first threaded rod 5 extend into the sliding seat 6, and the two sliding seats 6 are close to each other. One end is V-shaped. Such as figure 1 As shown, the left and right sides of the first base 2 and the second base 3 are respectively connected with a guide rod 4, the guide rod 4 passes through the sliding seat 6, and the guide rod 4 between the two sliding seats 6 is also connected to the guide rod 4. Cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com