Absolute position type multi-legged robot servo steering engine

A multi-legged robot and servo steering gear technology, applied in the field of robotics, can solve problems such as unsafe and precise search actions, increase hardware structure costs, and reduce customer experience, etc., to facilitate miniaturization and modularization, and improve safety and accuracy, size and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

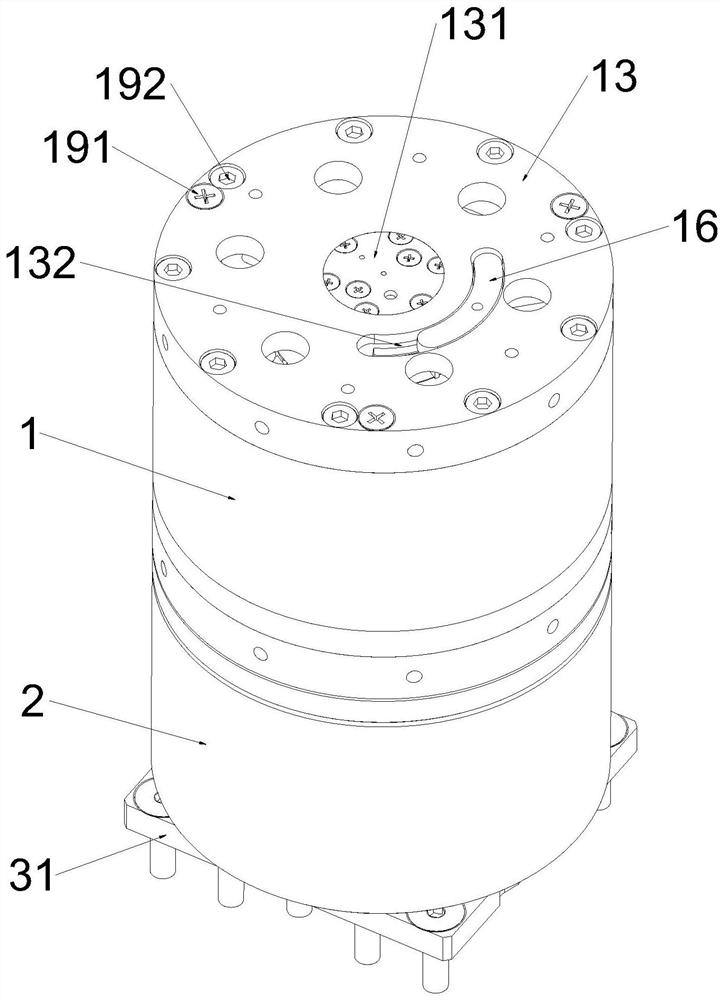

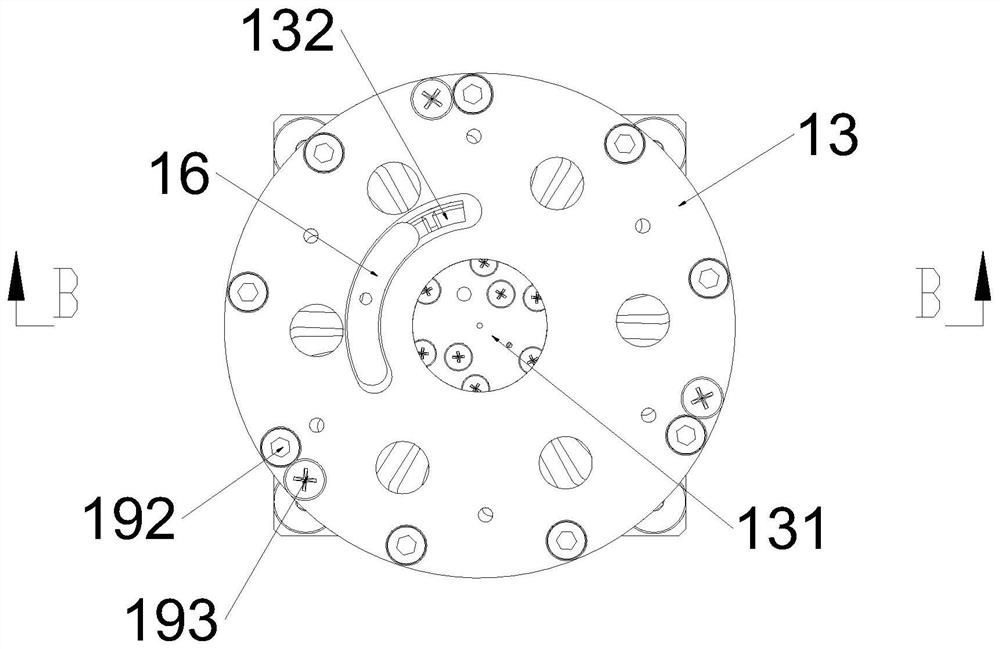

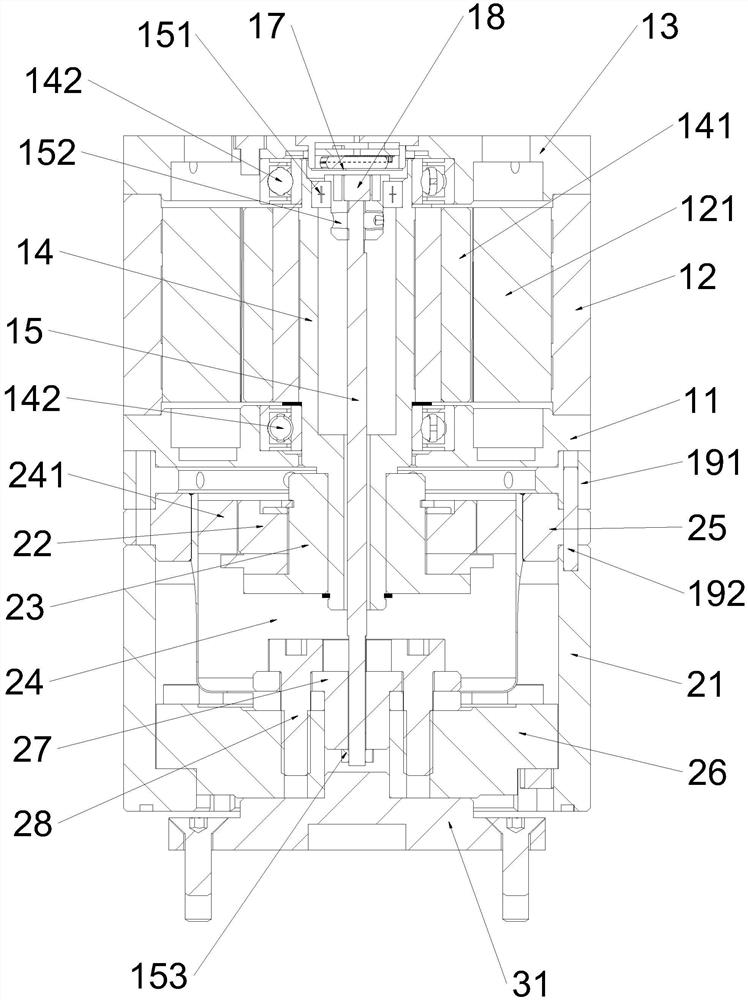

[0022] see Figure 1-3 , the present invention relates to an absolute position multi-legged robot servo steering gear, including a motor 1, a reducer 2, the motor 1 includes a motor front cover 11, a motor casing 12, a motor rear cover 13, a motor output shaft 14, a stator 121. Rotor 141, the motor front end cover 11 and the motor rear end cover 13 are respectively covered on the front and rear ends of the motor casing 12, the reducer 2 is fixed on the motor front end cover 11, and the motor output shaft 14 is set On the central axis of the motor housing 12, it is rotatably connected with the motor front end cover 11 and the motor rear end cover 13 respectively. The front end of the motor output shaft 14 extends into the reducer 2 and is connected with the input end of the reducer 2. The rotor 141 is fixed on the peripheral side of the motor output shaft 14, and the stator 121 is fixed on the inner wall of the motor housing 12, and also includes a Hall array encoding chip 17, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com