Leg assembly of multi-legged robot

A multi-legged robot and leg technology, applied in the field of robotics, can solve the problems of increasing the axial length of the motor, large volume, and poor precision of the planetary reducer, and achieve reduced volume and weight, accurate output angle, and short axis The effect of end size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

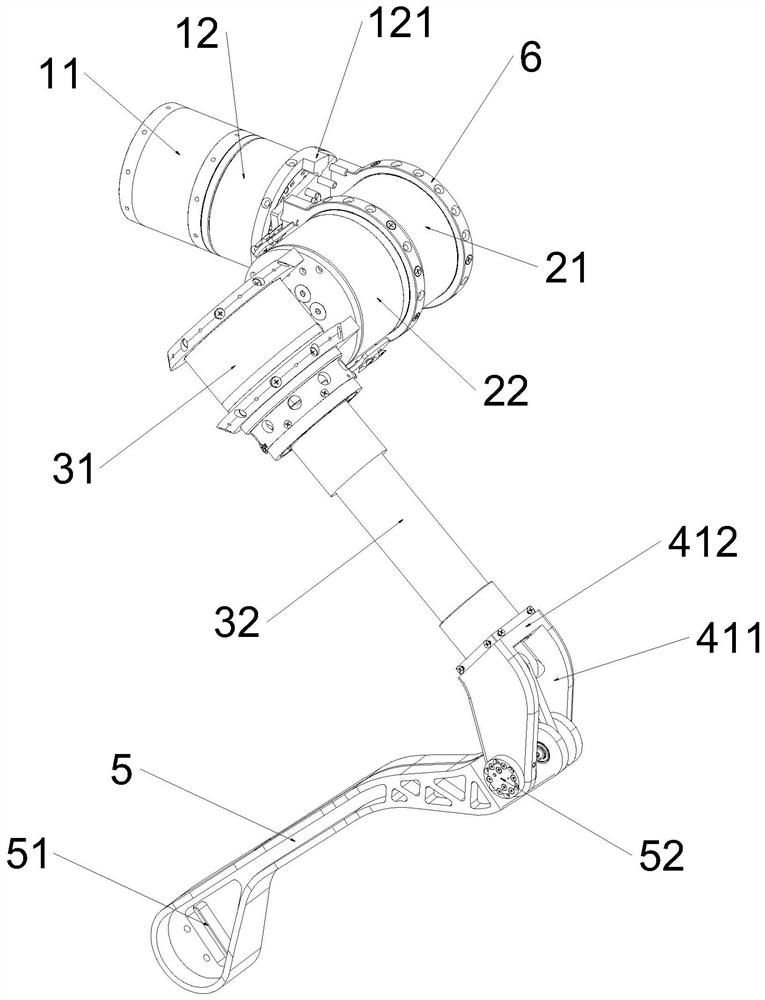

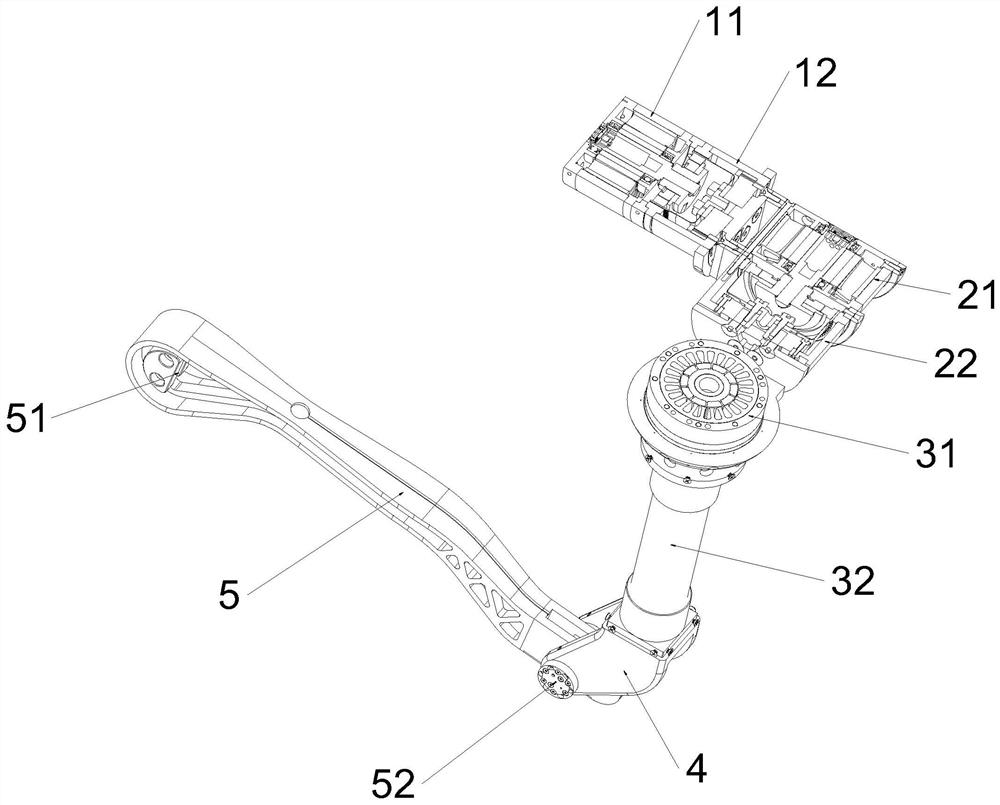

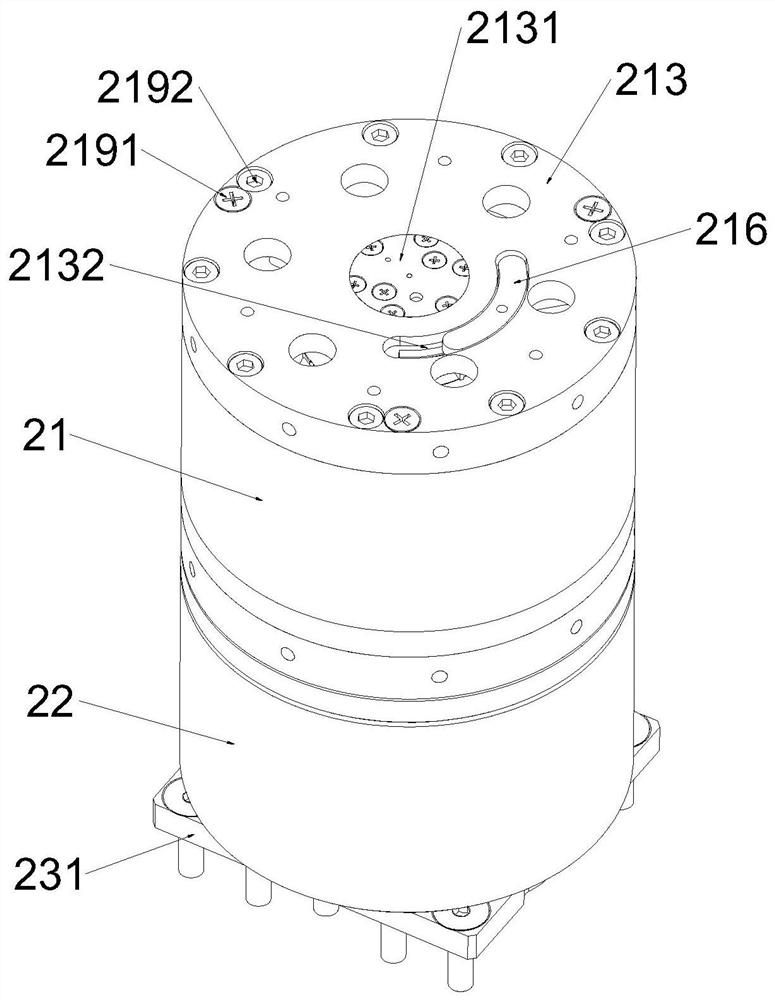

[0034] see Figure 1-2 , the present invention relates to a leg assembly of a multi-legged robot, which is characterized in that: a first steering gear 1, a second steering gear 2, a third steering gear 3, a crankshaft linkage mechanism 4, a calf support 5, the first The steering gear 1 includes a first motor 11 and a first speed reducer 12 that are assembled and connected, the second steering gear 2 includes a second motor 21 and a second speed reducer 22 that are assembled and connected, and the third steering gear 3 includes a first motor that is assembled and connected. Three motors 31 and screw mechanism 32, please refer to Figure 5 , the first motor 11, the second motor 21, and the third motor 31 all include a motor housing and a motor output shaft 214, and the motor output shaft 214 is rotatably arranged on the central axis of the motor housing. The center of the rear end of the casing is fixed with a Hall array encoding chip 217, and the Hall array encoding chip 217 ...

Embodiment 2

[0093] see Figure 1-2 , in order to achieve the above object, the present invention also provides another multi-legged robot leg assembly, including a first steering gear 1, a second steering gear 2, a third steering gear 3, a crankshaft linkage mechanism 4, and a leg support 5, The first steering gear 1 includes a first motor 11 and a first speed reducer 12 that are assembled and connected, the second steering gear 2 includes a second motor 21 and a second speed reducer 22 that are assembled and connected, and the third steering gear 3 Including assembling and connecting the third motor 31 and the screw mechanism 32, the first motor 11, the second motor 21, and the third motor 31 all include a motor housing, a motor output shaft 214, and the motor output shaft 214 rotates and is located on On the central axis of the motor housing, the rear end center of the motor housings of the first motor 11 and the second motor 21 is fixed with a Hall array encoding chip 217, and the Hall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com