A multi-layer screen printing device for helmets with the function of filling ink

A technology of screen printing device and safety helmet, which is applied in the direction of screen printing machine, printing, printing machine, etc., can solve the problems of contamination of safety helmet, damaged characters and patterns, and inability to print with ink on safety helmet, so as to ensure that it is not damaged, The effect of reducing ink condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

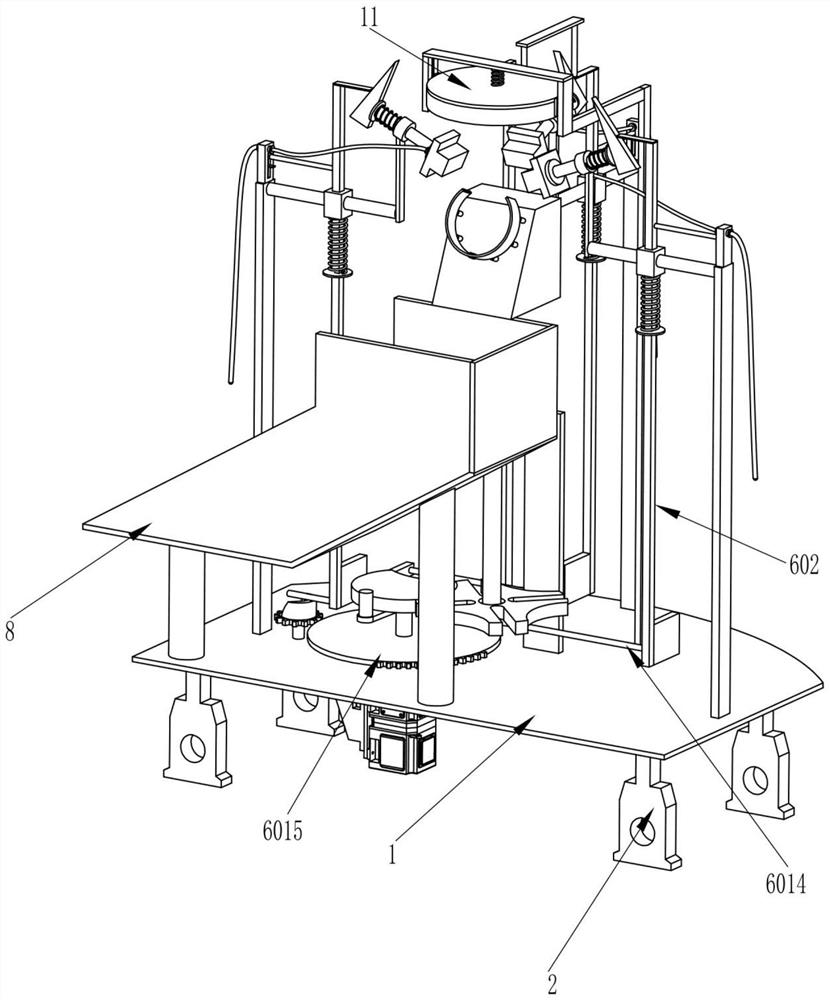

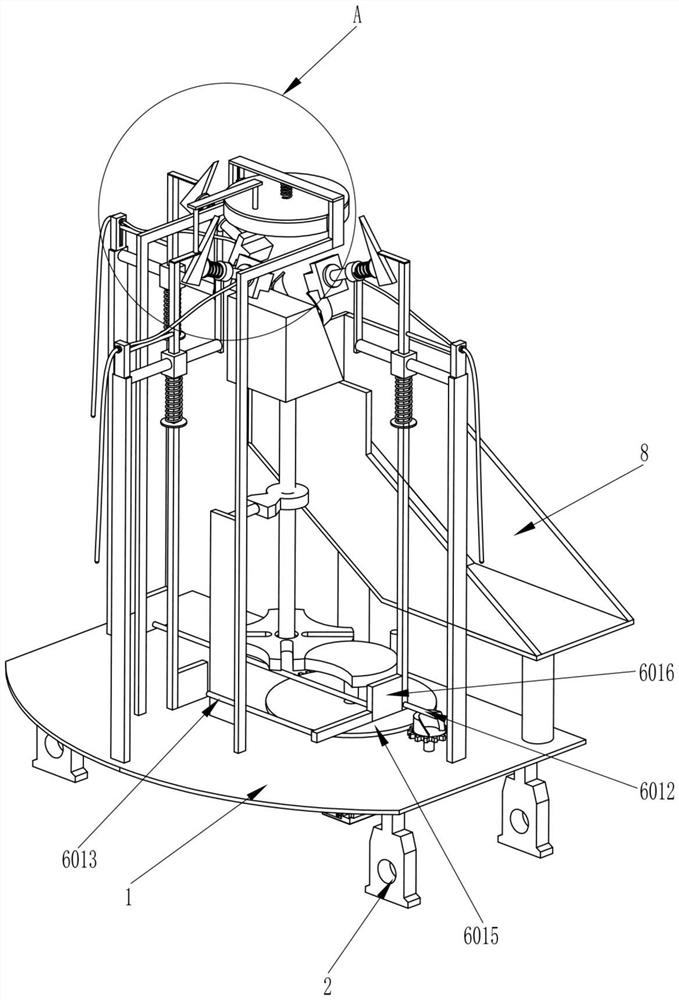

[0023] A multi-layer screen printing device for safety helmets with the function of adding ink, such as Figure 1-7 As shown, it includes an arc panel 1, a base 2, an intermittent rotating part 3, a helmet screen printing part 6, an ink automatic refilling part 7 and a guide frame 8, and the upper ends of the four bases 2 are fixedly equipped with an arc panel 1, so The intermittent rotating part 3 is installed on the upper side of the arc panel 1, the intermittent rotating part 3 is used to drive the helmet that needs silk screen to rotate clockwise intermittently, and the helmet silk screen part 6 is installed on the upper side of the arc panel 1 And connected with the intermittent rotating part 3, the helmet silk screen printing part 6 is used to perform three silk screen printing operations on the safety helmet on the intermittent rotating part 3 successively, and the ink automatic replenishment part 7 is arranged on the helmet silk screen printing part 6, so The guide fra...

Embodiment 2

[0029] On the basis of Embodiment 1, such as Figure 5-6 As shown, the ink automatic replenishment component 7 for automatically filling ink on three screen printing cottons 607 includes a movable frame 701, a sliding block 702, a connecting rod 703, a telescopic hose 704, an infusion hose 705, a pushing plate 706 and a third compression spring 707, the movable frame 701 is fixedly installed on the upper side of the guide frame 601, the third compression spring 707 is installed in the movable frame 701, and a sliding spring 707 is installed on the upper end of the third compression spring 707 Stopper 702 and sliding stopper 702 sliding type are positioned at movable frame 701, and described sliding stopper 702 is fixedly installed with pushing plate 706, and described connecting rod 703 is fixedly installed on the guide bar 602 and connecting rod 703 can be connected with pushing plate 706, the connecting rod 703 is used to drive the push plate 706 to move up and down, one end...

Embodiment 3

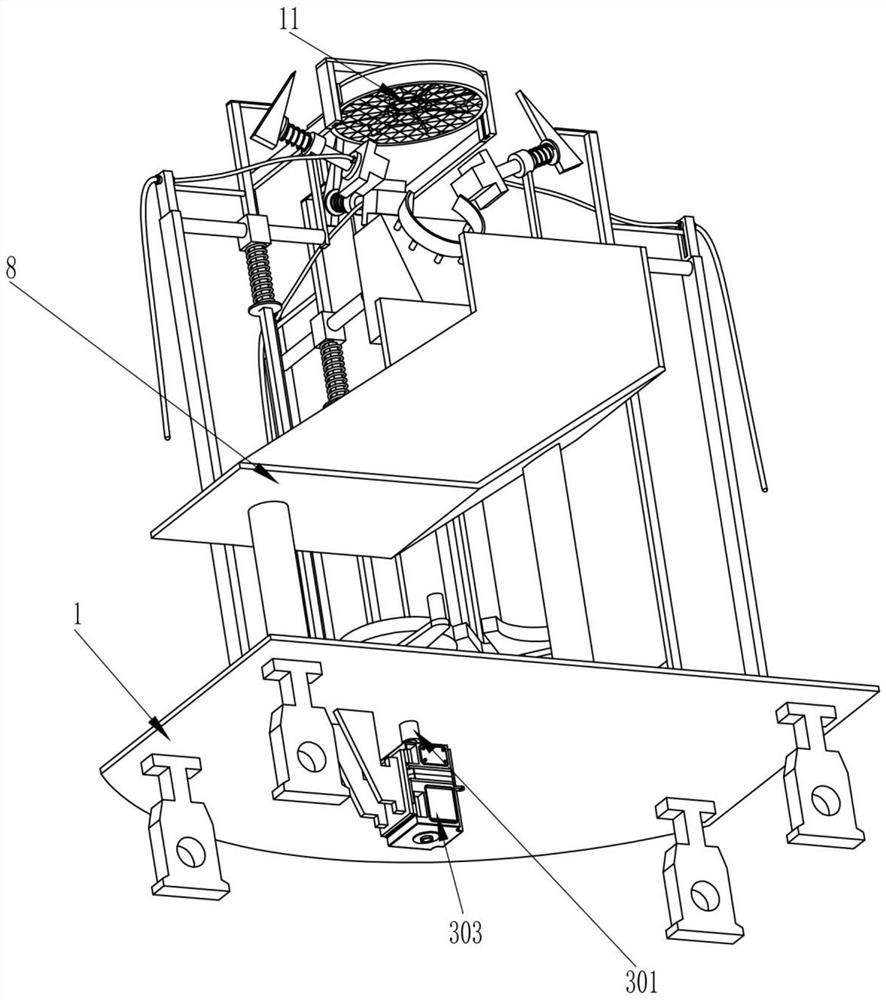

[0032] On the basis of Example 2, such as Figure 7 As shown, it also includes a support plate 9, a sliding frame 10, a heating fan 11, a fourth compression spring 12 and a connecting frame 13. The upper side of the arc panel 1 is fixedly equipped with two support plates 9, and the two support plates 9 The upper end of the sliding frame 10 is fixedly installed, the fourth compression spring 12 is installed on the bottom side of the upper part of the sliding frame 10, and the heating fan 11 is installed on the lower end of the fourth compression spring 12 and is in sliding contact with the sliding frame 10, so The heating fan 11 is used to speed up the air-drying speed of the ink on the helmet, and a connecting frame 13 is fixedly installed between the upper side of the heating fan 11 and the upper side of one of the push plates 604 .

[0033] When one of the push plates 604 moves up and down, the heating fan 11 will be driven to move up and down by the connecting frame 13. Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com