Rapid construction method for elastic supporting block type monolithic track bed

A technology of integral ballast bed and elastic support, which is applied in the direction of roads, tracks, and ballast layers, can solve the problems of low rail assembly speed, non-straight expansion joints, and low hoisting efficiency, and achieve good social and economic benefits and improve Construction efficiency and the effect of improving hoisting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with specific examples.

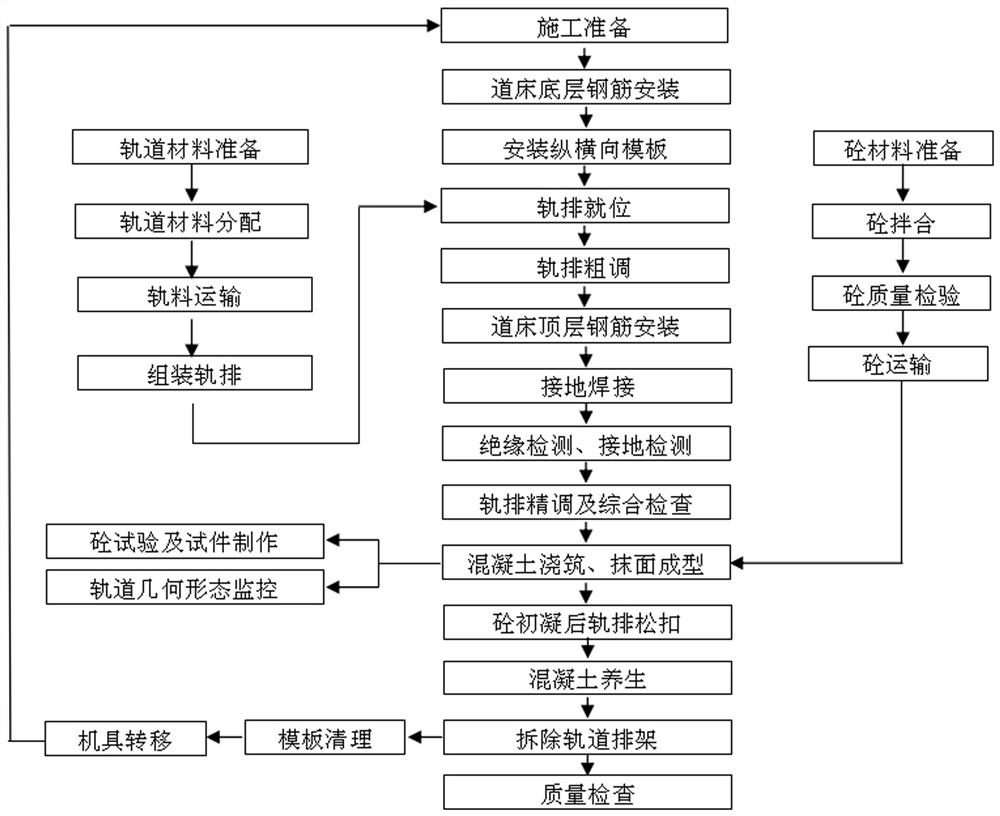

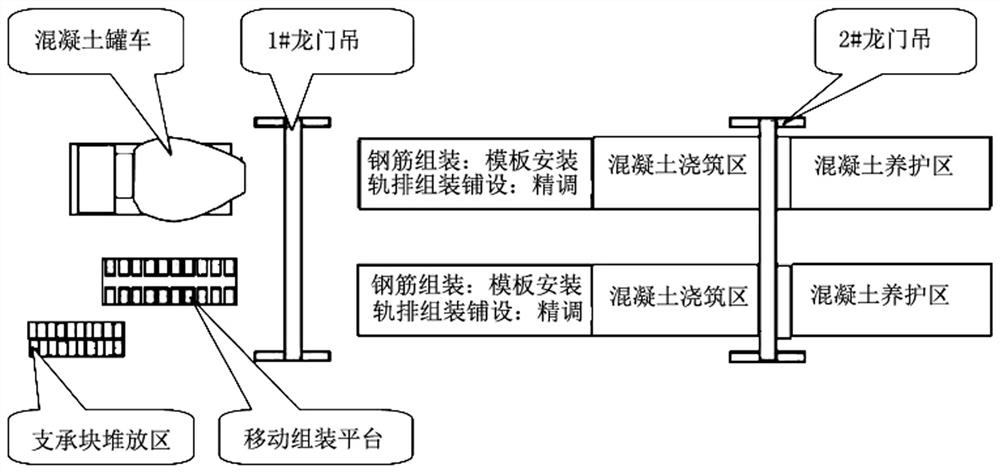

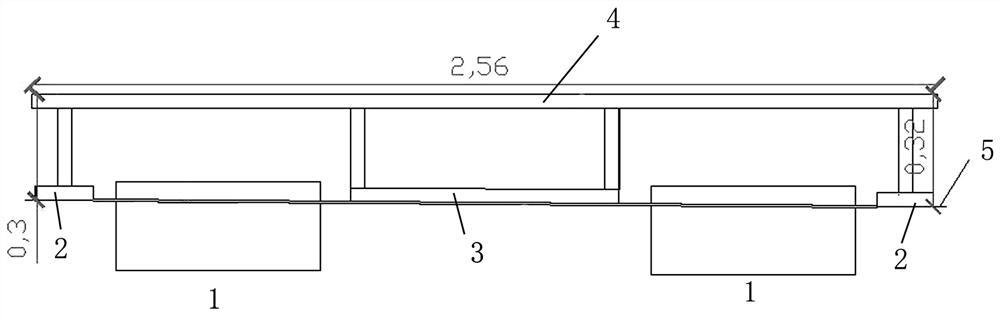

[0038] A rapid construction method of an elastic supporting block type integral ballast bed, comprising the following steps:

[0039] (1) Construction preparation: Before construction, conduct penetration measurement in the construction range of the ballast bed and adjacent sections, and start construction after adjusting and closing the center line and elevation;

[0040] (2) Transportation and placement of steel bars and support blocks: Place steel bars and support blocks along both sides of the ditch to ensure that they do not affect the construction passage, and at the same time meet the requirements for hoisting when assembling rail rows;

[0041] (3) Measuring and setting out: measure and set out the center line of the track and the four side pile points of the formwork on the inverted arch filling layer every other length of the track bed slab through the CPII control p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com