Metal-carbon fiber reinforced resin material composite and method for producing metal-carbon fiber reinforced resin material composite

A resin material and carbon fiber technology, which is applied in the field of metal-carbon fiber reinforced resin material composites, can solve the problems of low flexural strength, increased cost, weak compressive strength, etc., and achieve the effect of improving flexural strength and preventing electric corrosion

Active Publication Date: 2022-06-03

NIPPON STEEL CORP

View PDF10 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the compression strength of asphalt CFRP is very weak, so there is a problem of low flexural strength, and the cost increases when asphalt CFRP is used alone

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0228] The metal-CFRP composite of the present invention will be specifically described below by showing Examples and Comparative Examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Login to View More

Abstract

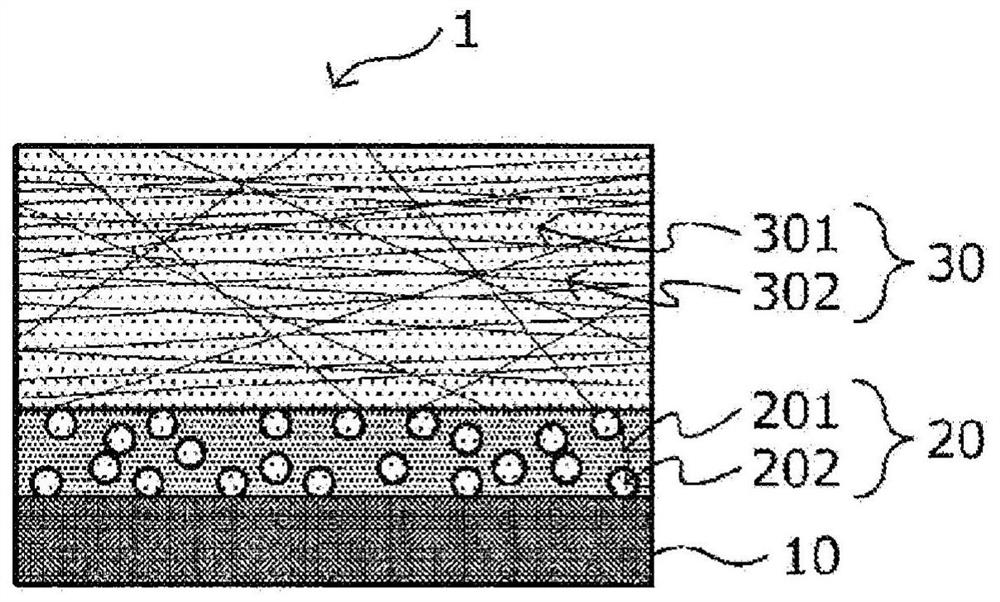

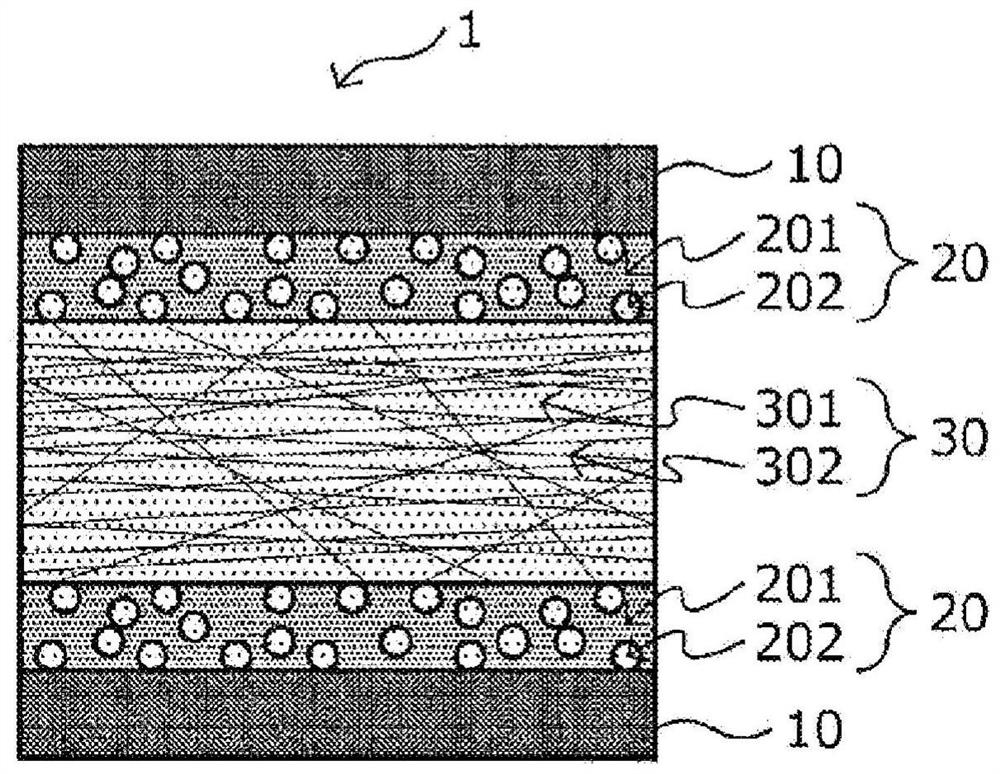

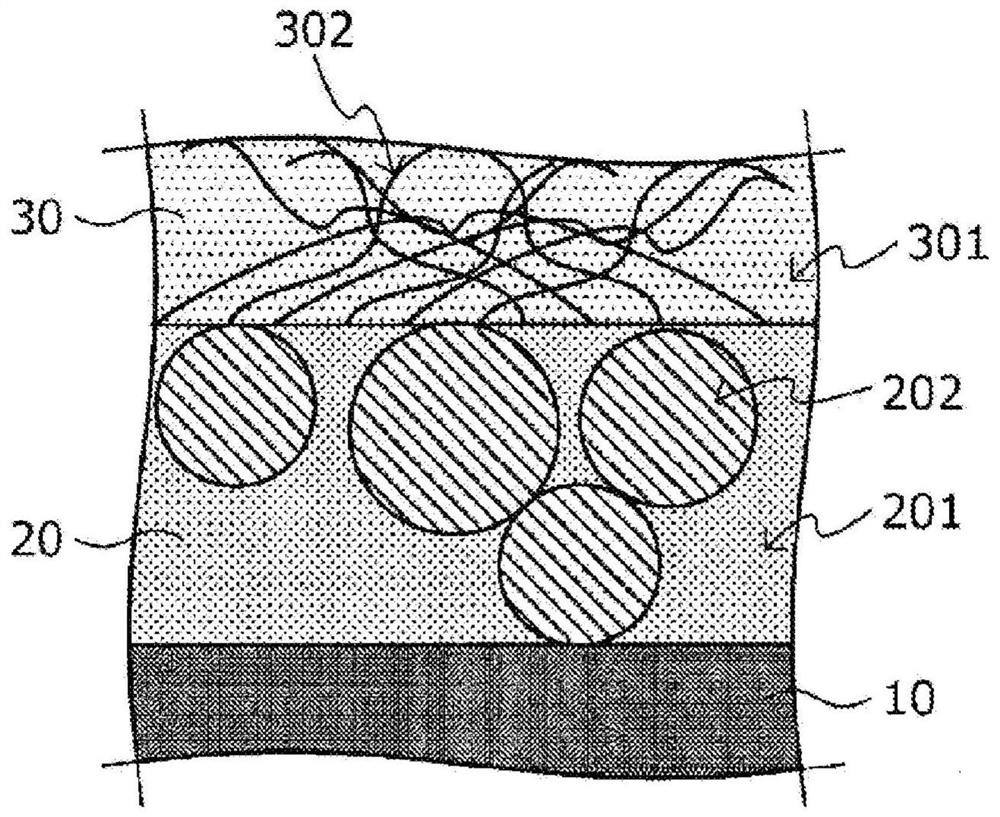

The metal-carbon fiber-reinforced resin material composite of the present invention includes a predetermined metal member, a resin layer located on at least part of the surface of the metal member, and a carbon fiber-reinforced resin material located on the resin layer, and the resin layer contains Inorganic fillers with a thermal conductivity of 20 W / (m·K) or more, the carbon fiber reinforced resin material contains a predetermined matrix resin and carbon reinforced fibers present in the matrix resin, and the carbon reinforced fibers have a thermal conductivity of 180 to At least one of pitch-based carbon-reinforced fibers in the range of 900 W / (m·K) and PAN-based carbon-reinforced fibers in the range of 100 to 200 W / (m·K) in thermal conductivity, the resin layer The content of the inorganic filler is in the range of 10 to 45% by volume relative to the total volume of the resin layer, and when the average particle diameter of the inorganic filler is X μm, the resin layer and the carbon fiber reinforced The number density of the inorganic fillers present in a region with a width of X μm in the direction of the interface of the resin material toward the resin layer is 300 / mm 2 above.

Description

technical field [0001] The present invention relates to a metal-carbon fiber reinforced resin material composite and a method for producing the metal-carbon fiber reinforced resin material composite. Background technique [0002] In recent years, various thermal managements have been required for automobiles. For example, in order to manage heat generated by batteries included in electric vehicles and hybrid vehicles, and to ensure battery safety and battery life, attention has been paid to components with high thermal conductivity. Specifically, the heat generated by the battery is managed by arranging a thermally conductive sheet, a copper heat pipe, or the like on the side surface portion or the bottom surface portion of the battery case. [0003] The above-mentioned thermally conductive sheet uses a member such as a resin (silicon) sheet from the viewpoint of reducing the weight of an automobile, but there is a problem that the strength of the resin sheet is lowered due ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B32B5/00B29C43/20B29C70/16B29C70/42B29C70/88B32B7/027B32B15/08B32B37/10B29K105/08B29L9/00

CPCB32B37/10B29C43/20B29C70/025B29C70/86B29C70/088B29C70/34B29C43/003B29K2305/00B29K2307/00B29K2105/0872B29K2101/12B29K2101/10B29C43/14B32B2250/02B32B2255/28B32B2262/0246B32B2262/106B32B2255/26B32B2307/302B32B2307/752B32B15/14B32B5/022B32B2260/046B32B2255/06B32B2264/10B32B2250/03B32B2457/10B32B15/18B32B2250/40B32B5/26B32B2260/021B32B2255/205B32B2264/107B32B15/20B32B2605/00B32B2307/206B32B2307/546B32B2264/102Y02E60/10B32B2264/303B29C43/203B29C70/42B29C70/683B29C70/78B29C70/88B29K2307/04B29K2705/00B29K2995/0013B32B5/02B32B37/06B32B37/182B32B2305/076B32B2305/10B32B2305/28B32B2305/30B32B2309/02B32B2309/04B32B2309/125B32B2311/20B32B2311/24B32B2311/30B32B2313/04B32B2315/02B32B2323/10B32B2363/00B32B2605/08

Inventor 臼井雅史茨木雅晴祢宜教之

Owner NIPPON STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com