Motor energization control method

A control method and motor technology, which is applied in the direction of electric steering mechanism, steering mechanism, power steering mechanism, etc., to achieve the effect of smooth assist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

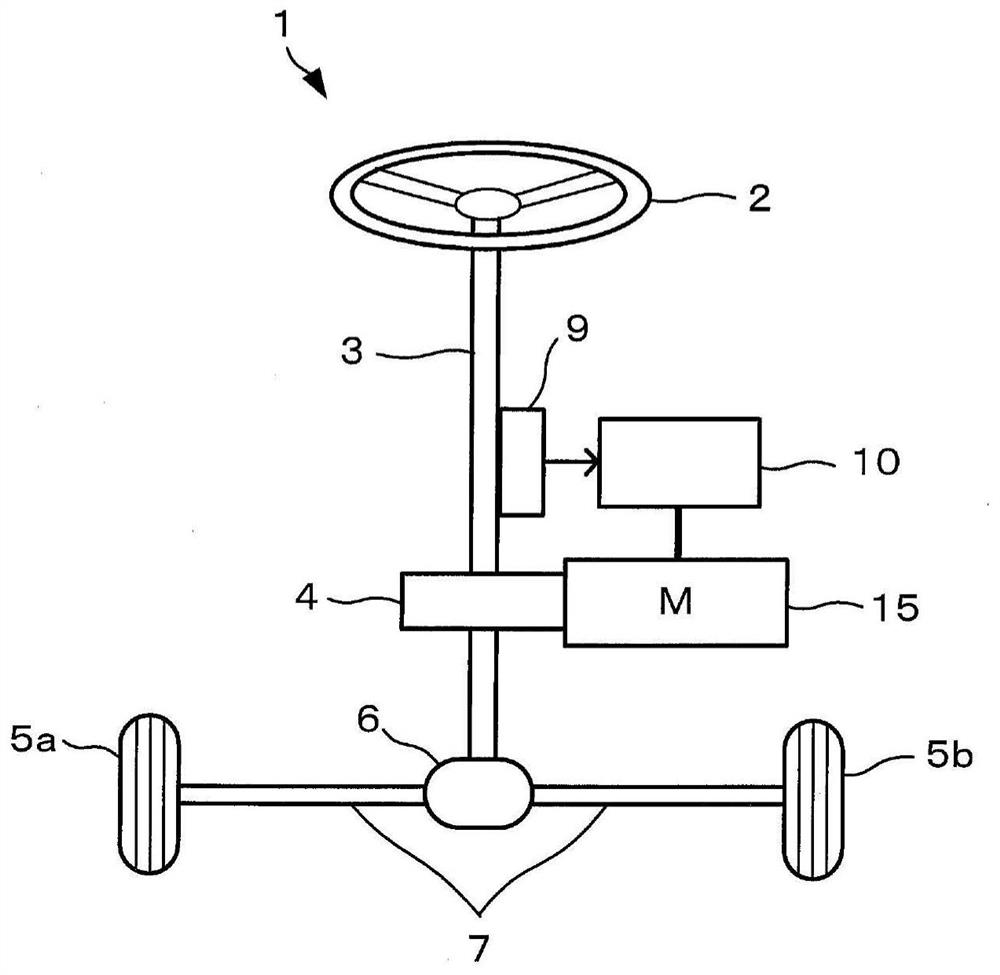

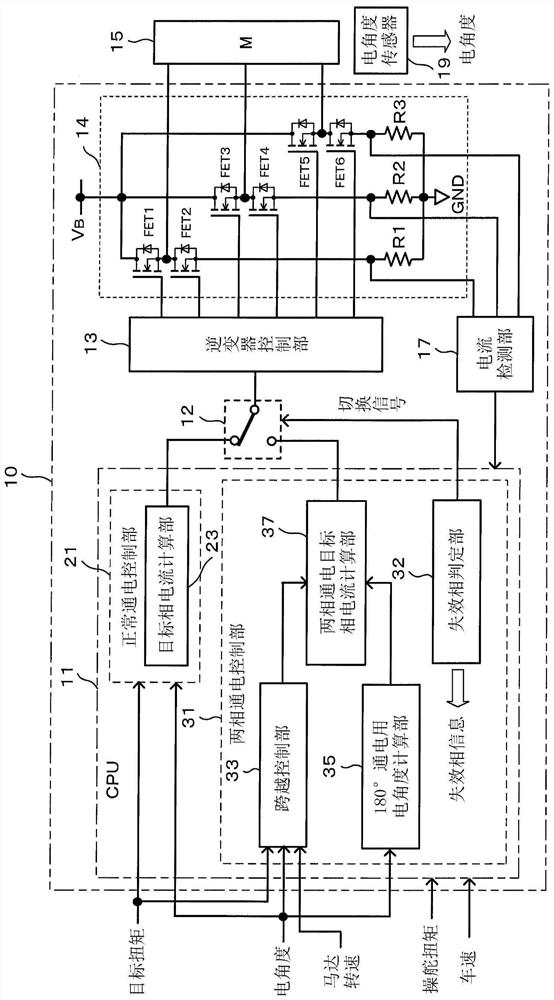

[0020] Hereinafter, one embodiment of the present invention will be described in detail with reference to the drawings. figure 1 It is a schematic configuration of an electric power steering device (system) using a motor energization control method according to an embodiment of the present invention. figure 1 The electric power steering device 1 has a motor control device 10 as an electronic control unit (Electronic Control Unit: ECU), a steering wheel 2 as a steering member, a rotating shaft 3 connected to the steering wheel 2, a pinion 6, a rack shaft 7, and the like. .

[0021] The rotary shaft 3 meshes with a pinion 6 provided at the front end thereof. The rotary motion of the rotary shaft 3 is converted into the linear motion of the rack shaft 7 by the pinion 6, and the pair of wheels 5a, 5b provided at both ends of the rack shaft 7 are steered so as to correspond to the displacement of the rack shaft 7. Angle.

[0022] A torque sensor 9 for detecting a steering torque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com