Automatic winding device for cable manufacturing

A winding device and cable manufacturing technology, which is applied in the direction of transportation and packaging, thin material handling, and delivery of filamentous materials, etc., can solve the problems of loose cables, low cable tightness, and poor winding effects, and achieve winding Efficiency improvement, the effect of improving the winding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

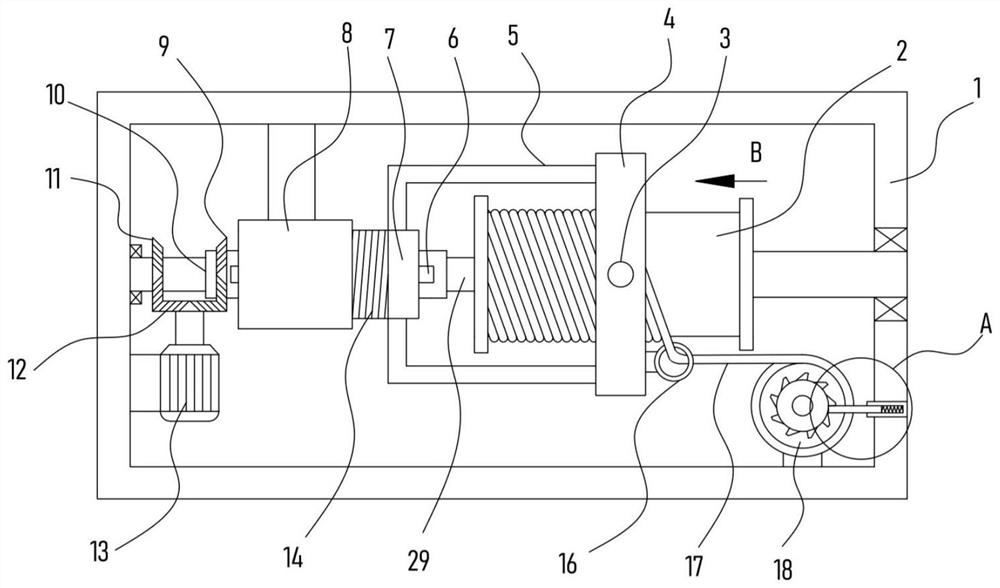

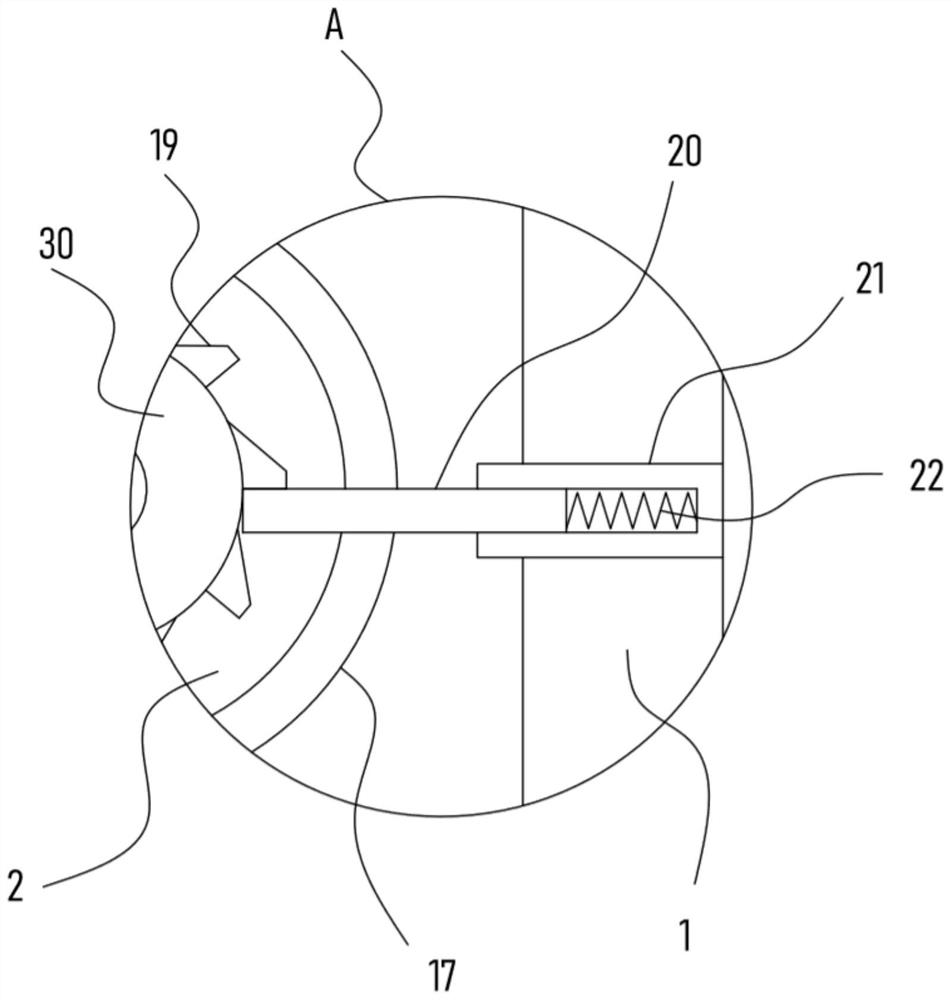

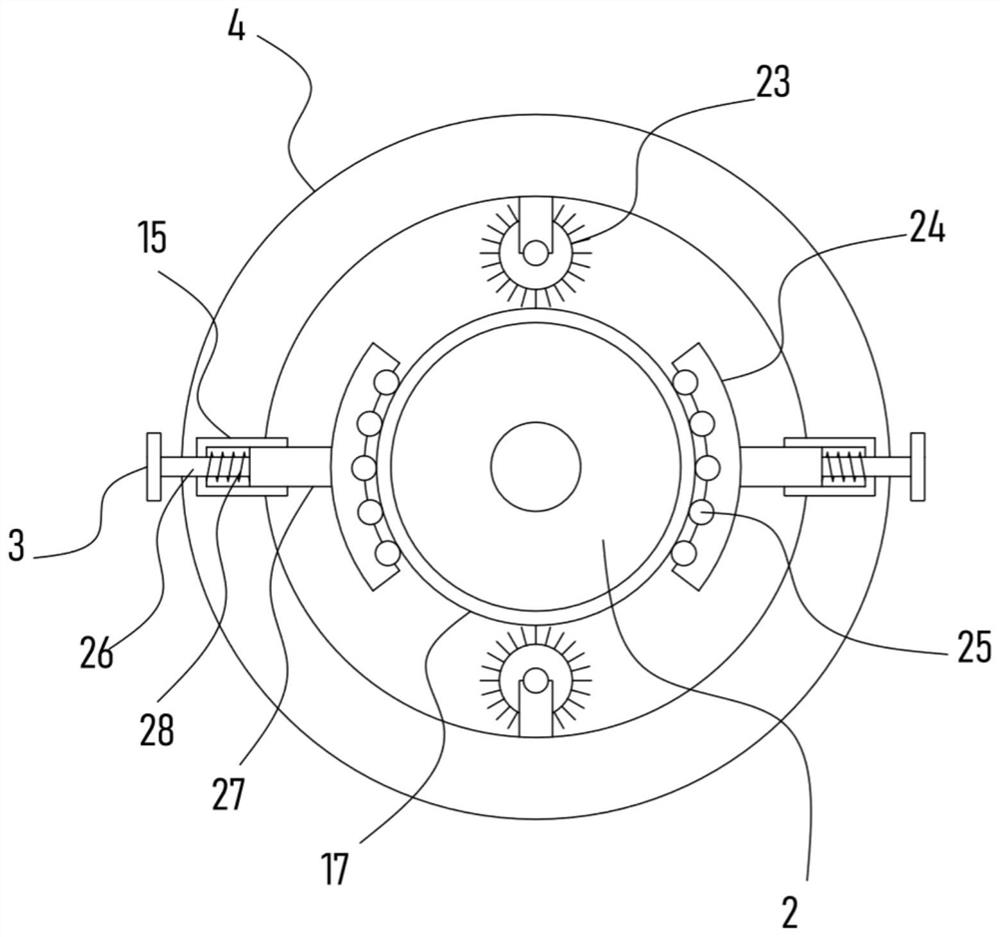

[0022] see Figure 1-4 , an automatic winding device for cable manufacturing, comprising a support frame 1, a drive motor 13 is fixed on the support frame 1, and the support frame 1 is rotatably equipped with a placement roller 18 for laying cables 17, and the support frame 1 rotates A winding roller 2 for winding the cable 17 is installed, the winding roller 2 is sleeved with a ring frame 4, the ring frame 4 is fixed with a limit ring 16 for the cable 17 to pass through, and the ring frame 4 is provided with a rolling mechanism for rolling the cable 17. A driving shaft 29 is coaxially fixed on the winding roller 2, and a translation mechanism for driving the translation of the ring frame 4 is connected to the driving shaft 29. The output shaft of the driving motor 13 is driven and connected with a rotating mechanism for driving the ring frame 4 to rotate relative to the winding roller 2, and the placing roller 18 is provided with a one-way positioning mechanism.

[0023] The...

Embodiment 2

[0029] On the basis of Embodiment 1, in addition, this device is also provided with a rotating mechanism, including a bevel gear III12 coaxially fixed with the output shaft of the drive motor 13, and the bevel gear III12 is meshed and connected with respectively sleeved and fixed on the drive shaft 29. And bevel gear II11 and bevel gear I9 on the rotary tube 10.

[0030] The drive motor 13 is used to drive the bevel gear III12 to rotate, and the bevel gear III12 simultaneously drives the bevel gear II11 and the bevel gear I9 meshed with it to rotate, thereby realizing the reverse rotation of the drive shaft 29 and the rotating tube 10. The winding roller 2 realizes reverse rotation, that is, the winding efficiency of the cable 17 by the winding roller 2 is significantly improved, and the rolling efficiency of the cable 17 by the rolling mechanism is significantly improved.

[0031] Further, the one-way positioning mechanism of the device includes a running wheel 30 coaxially f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap