An intelligent drying equipment for processed mosquito coils

A technology for processing molding and drying equipment, which is applied in lighting and heating equipment, drying, drying machines, etc., can solve the problems of high water absorption of mosquito coils, failure to ensure the continuity of mosquito coils, and high defective rate of mosquito coils, and achieve drying speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Now in conjunction with accompanying drawing, the present invention is further elaborated.

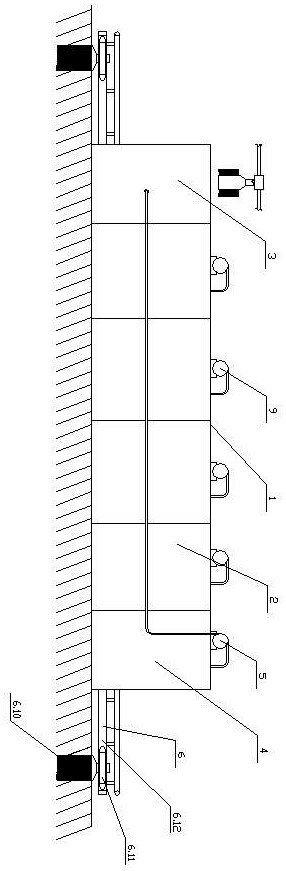

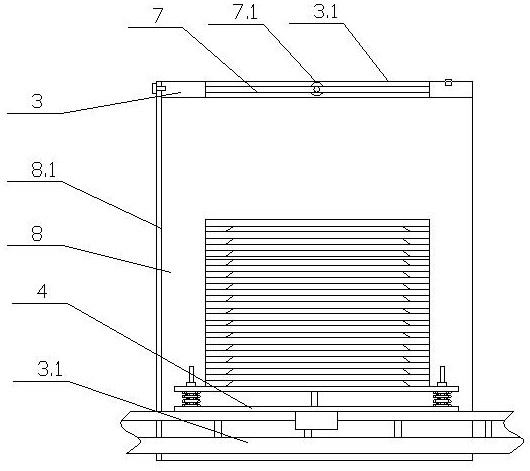

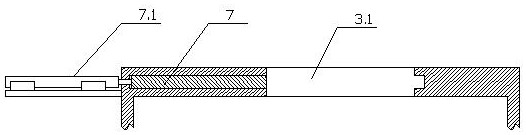

[0019] Such as Figure 1-10 As shown, a kind of intelligent drying equipment after mosquito coils are processed and formed, including a drying tunnel 1, an air heating unit 2, a loading workshop 3 and a blanking workshop 4, on the ground in front of the drying tunnel 1 through bolts There are multiple fixed air heating units 2, and each air heating unit 2 is connected to the drying tunnel 1, and the hot air is generated and sent to Go to the drying tunnel 1 to dry the mosquito-repellent incense, and the two ends of the drying tunnel 1 are fixed by welding with the loading workshop 3 and the unloading workshop 4, which are respectively used for the feeding and discharging of the mosquito-repellent incense in the drying tunnel 1 , the same material conveying unit 6 is set in the drying tunnel 1, the loading workshop 3 and the unloading workshop 4, and the circulation track 6.13 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com