Auxiliary containing equipment for manufacturing scale paper of thermometer

A thermometer and scale technology, used in thermometers, devices for coating liquid on surfaces, thermometers based on material expansion/contraction, etc. The effect of saving manpower and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

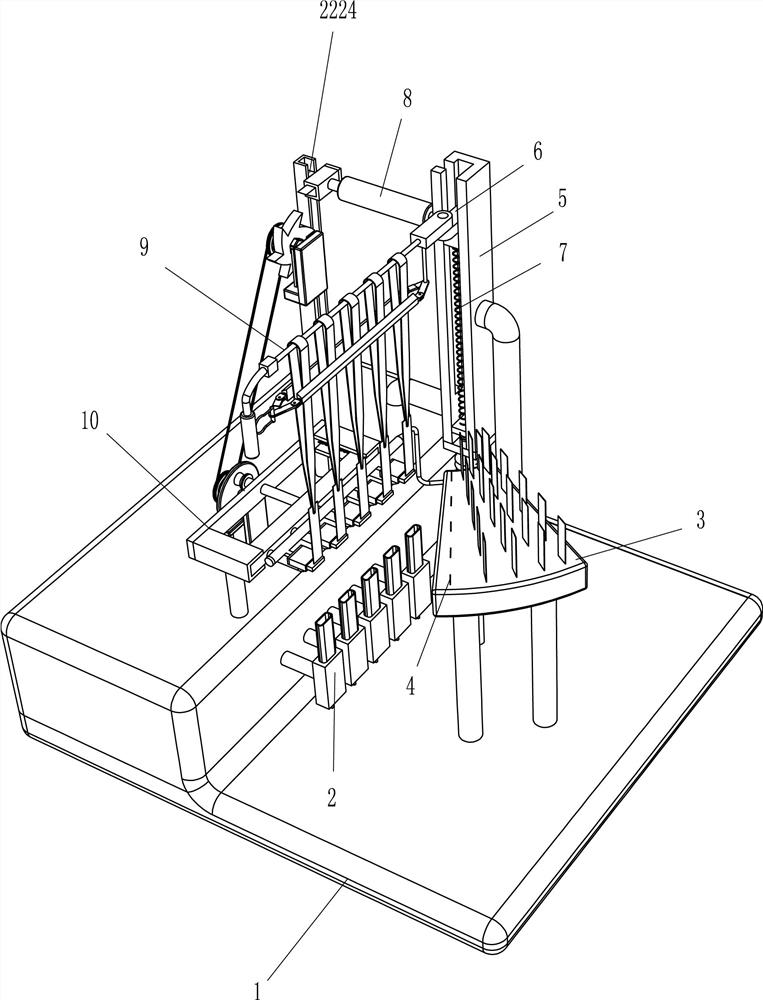

[0026] An auxiliary device for making scale paper for thermometers, such as Figure 1-3 As shown, it includes a base 1, a placement box 2, a fan-shaped plate 3, a slide rail 5, a slider 6, a first elastic member 7 and a handle 8, and the right side of the base 1 is connected with five placement boxes 2 at even intervals, and the base 1 The fan-shaped board 3 is connected to the right side of the top, and there are multiple groups of slots 4 evenly spaced on the left and right sides of the top of the fan-shaped board 3, and the number of each group of slots 4 is five. A slider 6 is slidably connected within the 5, a first elastic member 7 is connected between the slider 6 and the slide rail 5, a handle 8 is connected to the left side of the slider 6, and a clamping device 9 and a gluing device 10 are also included. A clamping device 9 is provided on the slider 6 , and a gluing device 10 is provided on the base 1 .

[0027] The clamping device 9 includes a first swing lever 91,...

Embodiment 2

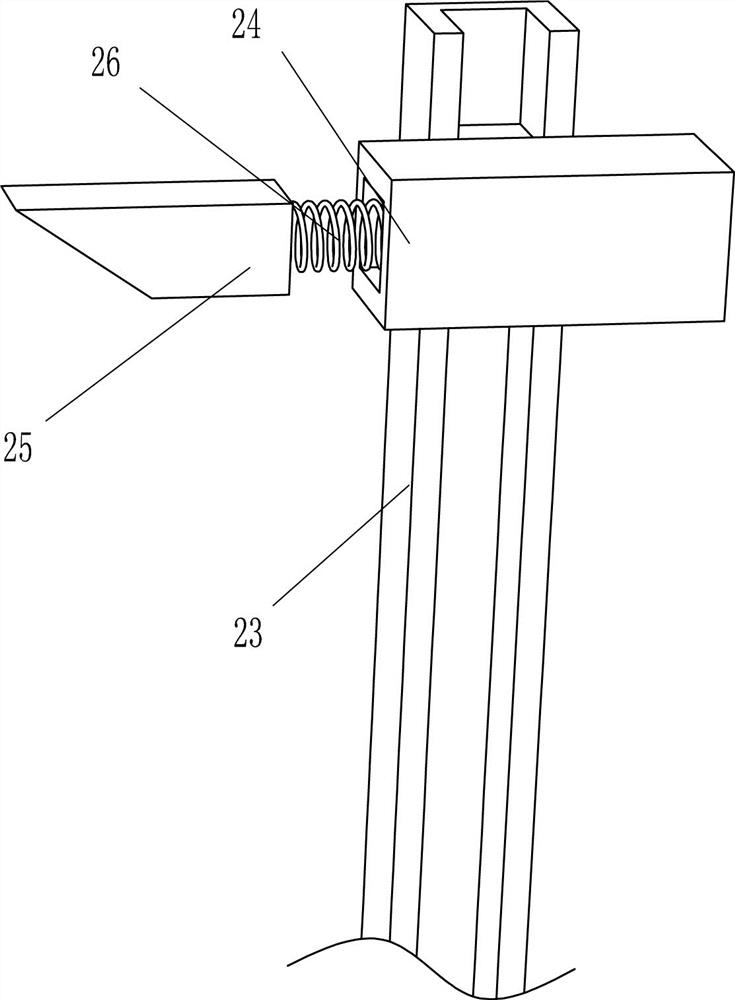

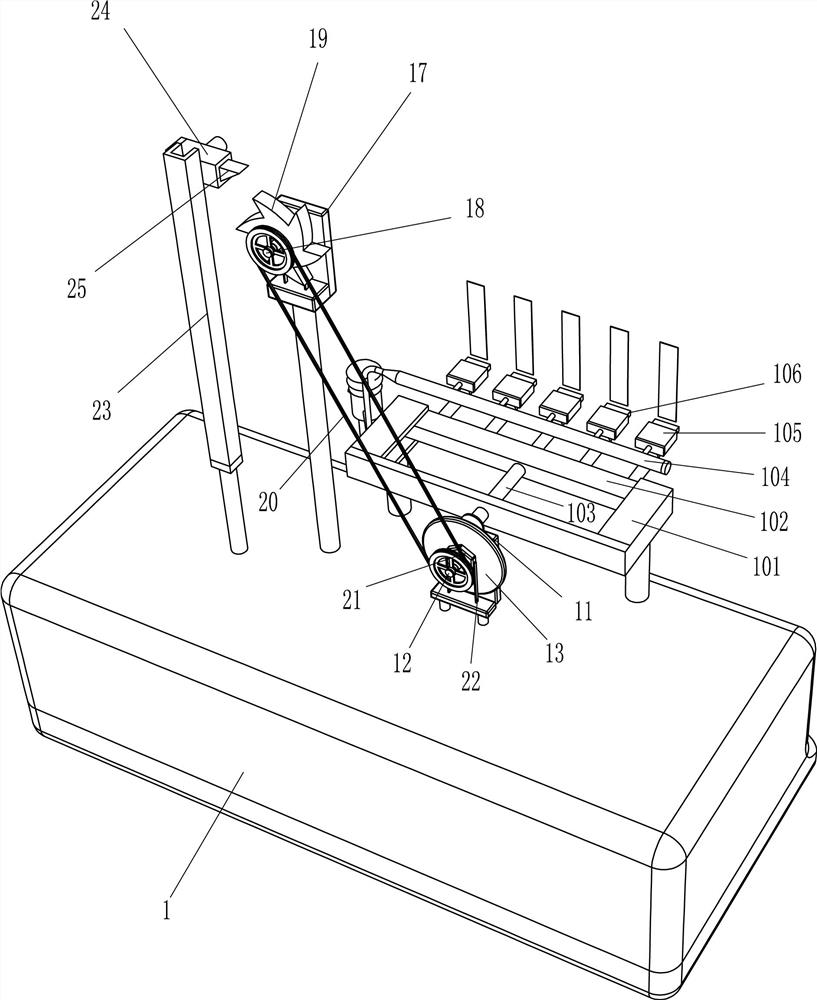

[0031] On the basis of Example 1, such as Figure 4-5As shown, it also includes a bearing seat 11, a first rotating shaft 12, a disc 13, a bump 14, a convex ball 15, a second elastic member 16, an L-shaped mounting frame 17, a second rotating shaft 18, a six-tooth ratchet 19, and a belt Transmission mechanism 20, hexagonal block 21, shrapnel 22, sliding track 23, square sliding sleeve 24, wedge-shaped top block 25 and the third elastic member 26, the left side of base 1 top is connected with bearing seat 11, and the bearing seat 11 is connected with The first rotating shaft 12, the first rotating shaft 12 is connected with a disc 13, the disc 13 is connected with three projections 14 evenly spaced along the circumferential direction, the left end of the movable rod 103 is connected with a convex ball 15, and the convex ball 15 will meet the projection 14 Contact, the second elastic member 16 is connected between the left side of the sliding frame 102 and the inner left side of...

Embodiment 3

[0034] On the basis of Example 2, such as Image 6 Shown, also comprise compressible container 27, hose 28, one-way valve 29, push rod 31 and the 4th elastic member 32, base 1 top right rear side is connected with compressible container 27, the discharge of compressible container 27 A flexible pipe 28 is connected between the end and the injection tube 104, and the liquid inlet end of the flexible pipe 28 and the compressible container 27 is provided with a one-way valve 29, and the inner bottom of the slide rail 5 has a square groove 30, and the sliding type in the square groove 30 A push rod 31 is connected, the bottom of the push rod 31 is in contact with the compressible container 27 , the top of the push rod 31 is in contact with the slider 6 , and a fourth elastic member 32 is connected between the push rod 31 and the inner bottom of the square groove 30 .

[0035] When the slide block 6 moves down to contact with the push rod 31, the slide block 6 continues to move down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com