360-degree rotating heavy transfer vehicle

A transfer vehicle, heavy-duty technology, applied in the direction of motor vehicles, vehicle maintenance, shunting equipment, etc., can solve the problems of limited height, narrow space, difficult transfer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

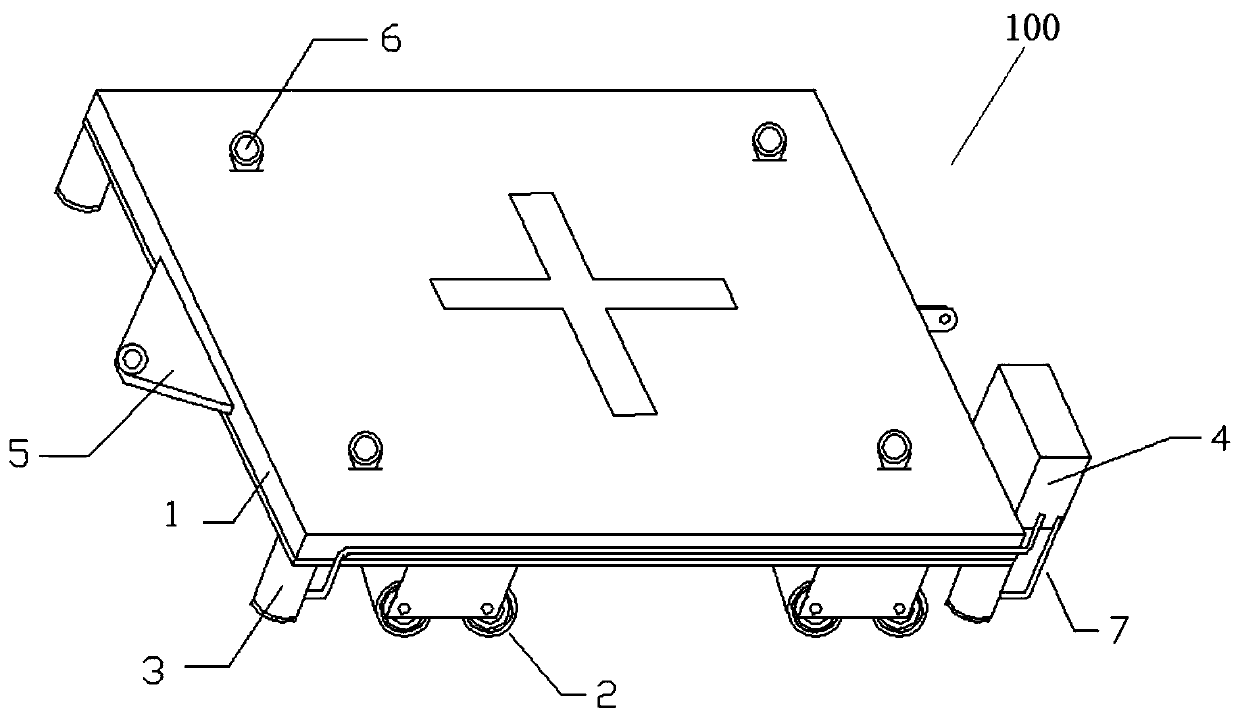

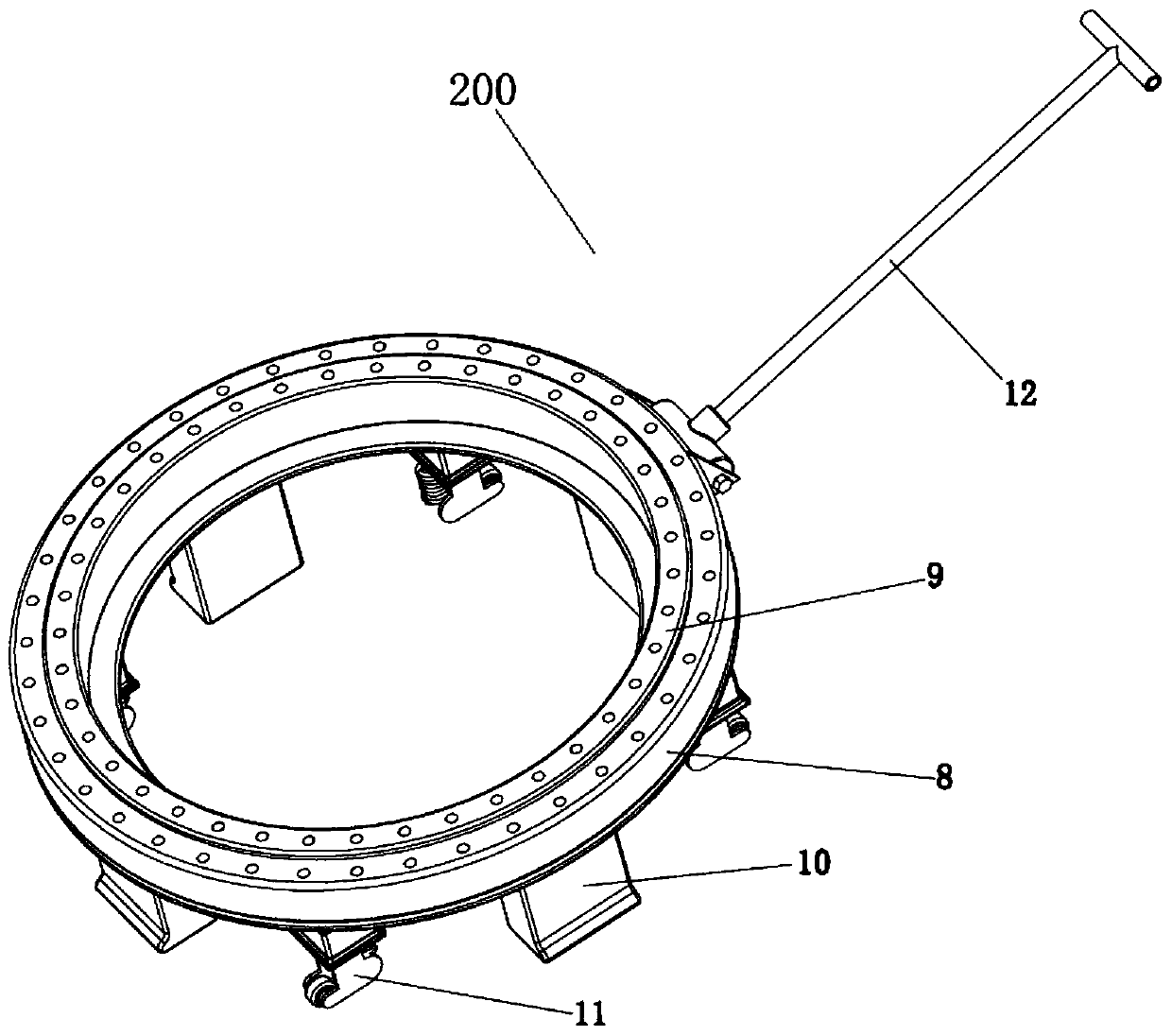

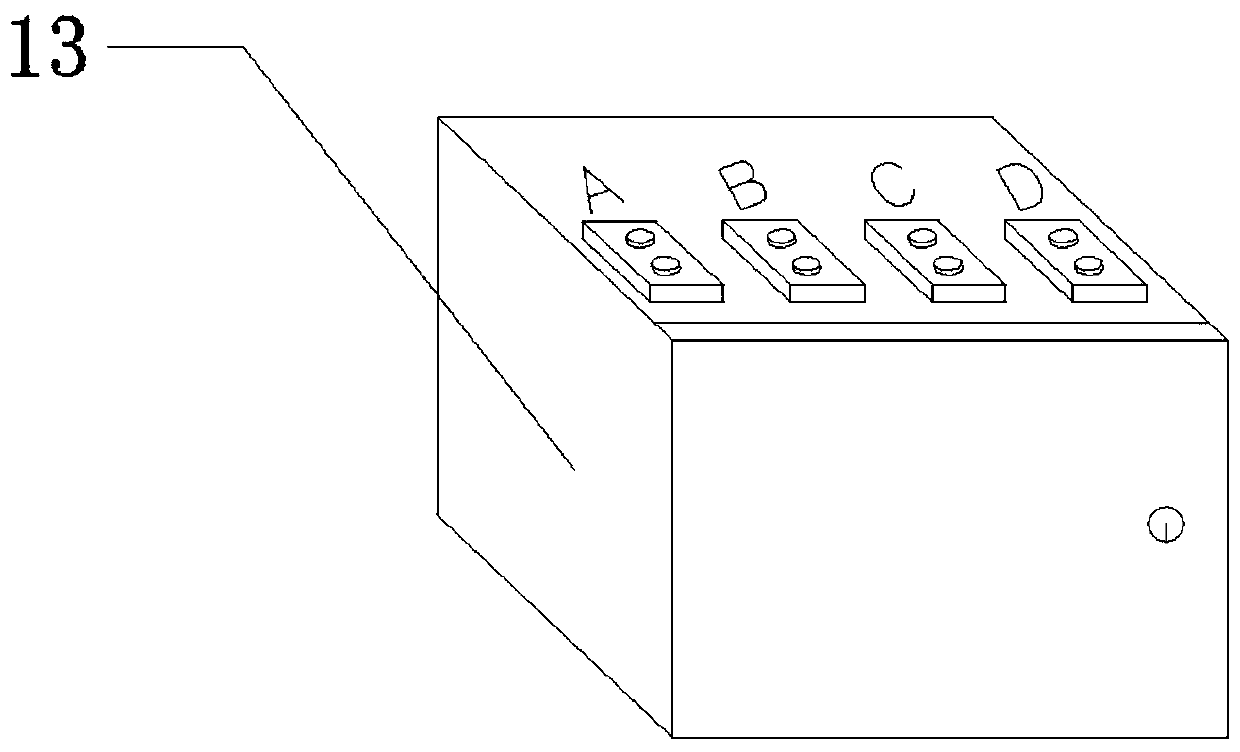

[0040] Such as Figures 1 to 5 As shown, a 360-degree rotating heavy-duty transfer vehicle includes a trolley body 100, a turntable 200 for 360° rotation of the trolley body, and an electro-hydraulic pump station 13; the trolley body 100 includes a trolley load platform 1, wheels 2 , a jack 3, a hydraulic station 4 and an oil pipeline 7; a plurality of wheels 2 are arranged under the trolley load platform 1, and at least one jack 3 is arranged near each of the wheels 2; each of the jacks 3 is respectively The hydraulic station 4 is communicated with the hydraulic station 4 through the oil pipeline 7; the hydraulic station 4 is connected with the electric hydraulic pump station 13; the hydraulic station 4 is provided with a hydraulic pressure relief valve;

[0041] The turntable 200 includes a turntable 8, a rotating ring 9, a support block 10 and a spring wheel 11; the turning ring 9 can rotate relative to the turntable 8, and the upper surface of the turning ring 9 is higher ...

Embodiment 2

[0043] Such as Figures 1 to 5 As shown, a 360-degree rotating heavy-duty transfer vehicle includes a trolley body 100, a turntable 200 for the trolley body to rotate 360°, and an electro-hydraulic pump station 13;

[0044] The trolley main body 100 includes a trolley load platform 1, wheels 2, jack 3, hydraulic station 4 and oil pipeline 7;

[0045] A plurality of wheels 2 are arranged under the trolley load platform 1, and at least one jack 3 is arranged near each wheel 2;

[0046] In practical applications, in order to better ensure that the trolley-carrying platform 1 runs smoothly and keeps it level as much as possible, at least three wheels 2 are provided at a time, preferably an even number greater than or equal to 4, and they are symmetrically distributed, so that it can be more Ensure that the trolley load platform 1 runs smoothly and keep it level as much as possible; the setting of the jack 3 is the same; with the ground, the connection mode of the wheel 2 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com